Technology Overview

Pressure sensitive adhesive (PSA, self adhesive, self stick adhesive) is adhesive that forms a bond when pressure is applied to marry the adhesive with the adherend. No solvent, water, or heat is needed to activate the adhesive. It is used in pressure sensitive tapes, labels, note pads, automobile trim, and a wide variety of other products.

As the name "pressure sensitive" indicates, the degree of bond is influenced by the amount of pressure which is used to apply the adhesive to the surface.

Surface factors such as smoothness, surface energy, removal of contaminants, etc. are also important to proper bonding.

PSAs are usually designed to form a bond and hold properly at room temperatures. PSAs typically reduce or lose their tack at cold temperatures and reduce their shear holding ability at high temperatures: Specialty adhesives are made to function at high or low temperatures. It is important to choose an adhesive formulation which is designed for its intended use conditions.

Applications of PSAs

Pressure sensitive adhesives are designed for either permanent or removable applications. Examples of permanent applications include safety labels for power equipment, foil tape for HVAC duct work, automotive interior trim assembly, and sound/vibration damping films. Some high performance permanent PSAs exhibit high adhesion values and can support kilograms of weight per square centimeter of contact area, even at elevated temperature. Permanent PSAs may be initially removable (for example to recover mislabeled goods) and build adhesion to a permanent bond after several hours or days.

Removable adhesives are designed to form a temporary bond, and ideally can be removed after months or years without leaving residue on the adherend. Removable adhesives are used in applications such as surface protection films, masking tapes, bookmark and note papers, price marking labels, promotional graphics materials, and for skin contact (wound care dressings, EKG electrodes, athletic tape, analgesic and transdermal drug patches, etc.). Some removable adhesives are designed to repeatedly stick and unstick. They have low adhesion and generally can not support much weight.

Food Industry

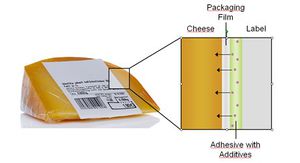

For the food packaging it is of high importance that none of the ingredients in an adhesive do not influence the quality of the food in an undesired way. Usually, the label is not directly applied to the food but on the package. Thus the packaging such as a plastic film is a barrier between the label and the food. This means that the adhesive - which is the sticky side of a label - is not in direct food contact. However, plastic films used for the food packaging can be very thin. The material is thin; such that depending on the chemical nature of an additive, migration through the film can occur (see picture). These products need to fully meet indirect food contact regulations to be certain that the quality of the food is not influenced in case an additive migrates through the film.

Pressure-sensitive adhesives may be safely used as the food-contact surface of labels and/or tapes applied to food, in accordance with the FDA CFR - Code of Federal Regulations Title 21

Other Industries

Other than food industry PSAs are widely used in

- Aerospace Industry

- Automobile Industry

- Electronics and Electrical Industry

- Medical Applications

Making of PSA

PSA products

The most common products that utilize PSAs are tapes, labels, and protective films. The PSA sector is among the fastest growing in the adhesive market, making the search for new pressure-sensitive products (PSP) and applications highly competitive.

- PSA tapes: Self-adhesive materials usually produced by coating an adhesive onto a carrier and used as a continuous web.

- PSA labels: Self-adhesive laminated carrier materials. The self-adhesive layer is protected with a supplemental material (release liner).

- Protective films: Carrier material possesses built-in or built-on self-adhesive properties.

Pressure Sensitive Adhesive Products in Food Industry

| S. No | Company | Product Name | Description |

| 1 | Sustainable Adhesive Products - Berkshire Labels Ltd | BioTAK™ S100 | Berkshire Labels, pioneers of thegreenlabelcompany.co.uk currently coat our S100 Permanent PSA onto a range of label stock substrates used in a variety of food labeling applications. |

| 2 | Exxon Mobil Corporation | Label-Lyte™ | Pressure-sensitive label facestocks for food packaging |

| 3 | Franklin Adhesives & Polymer | Pressure Sensitive Adhesives | Pressure sensitive adhesives for labels, tapes, films and office products marketed under the brand names of Covinax, Micronax and Acrynax. Adhesives offer various combinations of peel, tack and shear strength for specific applications – from packaging frozen foods to labels that can withstand the heat under the car hood. |

| 4 | Aqua Based Technologies | Aqua Tack 320 | Pressure sensitive adhesive for direct food contact. All levels of tack and shear are available. FDA 175.320 |

| 5 | Adhesive Technologies, Inc. | Formula 061 Hot Melt Pressure Sensitive Adhesive | Hot melt pressure sensitive adhesive being 100% solids containing no solvent. Excellent adhesion to PE and low energy surfaces. High peel adhesion and high initial tack. A qualified toxicologist has analyzed the components in Ad-Tech 061. This product is certified to be non-toxic. Additionally, Ad-Tech 061 meets FDA CFR 175.105 adhesive requirements for intermittent contact with food. |

Search Strategy for PSA

The search strategy page contains:

- Control Patents

- Patent class definitions

- Search Query

- Sample Patent Analysis

New Innovations

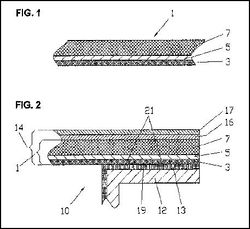

Reusable closures for packages

| Patent number | Date of publication | Assignee | Title | Abstract | Problem in prior art | Solution provided by patent | Image |

| EP2228211A2 | 9/15/2010 | AVERY DENNISON CORP | Reusable closures for packages and methods of making and using the same | The present invention relates to a method of providing a reusable closure for packages in the presence of moisture from refrigerated or frozen food packing environments, comprising (a) providing a package having a folding portion and a main portion wherein the folding portion is able to be folded over to cover the main portion of the package, (b) folding the folding portion over to close the package and (c) applying an adhesive article to the folded portion and the main portion so that the package remains closed, wherein the adhesive article comprises (i) a moisture resistant substrate having a first and second surface, and (ii) a removable adhesive covering at least a first portion of the first surface, wherein the removable adhesive has a Moist Loop Test result of at least about 0.8 N/25 mm at a test plate temperature of 5°C. | Manufacturers have proposed numerous forms of integrated means to provide a way of resealing a package, such as a frozen food bag. Consumers have typically used tape, clamps, twist ties, etc. to reclose packages. However, these systems are not entirely satisfying to consumers. | One solution to the resealing problem is to use a laminate with a pressure sensitive adhesive (PSA). If the adhesive is selected to provide removability, the consumer may open and reseal the package with the PSA laminate. The PSA laminate can provide easy application of the laminate, easy opening and closing of the package, and also writing or printing capabilities for identification of the package contents. |

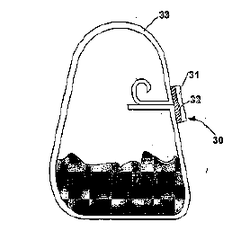

Adhesive clamp for closing a bag

| Patent number | Date of publication | Assignee | Title | Abstract | Problem in prior art | Solution provided by patent | Image |

| WO2011004271A2 | 1/13/2011 | EL TACK LTD | An adhesive clamp for closing a bag | An adhesive clamp for reclosing a packaging bag, the adhesive clamp comprises a tape having one side of the tape coated with an adhesive substance and a clamping strip of foldable non-elastic material attached to the adhesive side of the tape and where the tape is wider and longer than the clamping strip. | Prior art mentions about various reclosable techniques. Zipper pack known in the art consists of female and male zipper members provided at an opening of the pack. Zipper may easily collapse under external pressure. There are difficulties in manufacturing zipper packs, including increase in manufacturing cost. There are various types of fasteners for reclosing bags. Such fasteners are usually quite bulky and are bought independently of the package. However, such solutions are usually not at hand when a bag should be closed. Other solutions use an adhesive tack. After opening the bag, the user can fold the bag and use the tack to keep the edge folded. This type of solution is also advantageous as it includes the folding of the bag, which reduces the amount of air in the bag, thus reducing humidity and oxygen in the bag. However, this solution is effective only for a small number of opening and reclosing cycles. Another disadvantage is that the adhesive does not function in deep freeze conditions and the bag will not stay closed when in deep freeze conditions. | The invention is a a package-reclosing device devoid of the mentioned limitations. According to one aspect of the present invention there is provided an adhesive clamp for closing a packaging bag. |

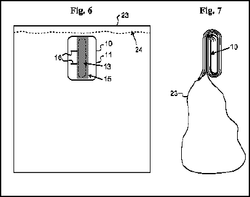

Multilayer Film

| Patent number | Date of publication | Assignee | Title | Abstract | Problem in prior art | Solution provided by patent | Image |

| US20080081183A1 | 4/3/2008 | DE BOER, Jurjen | Multilayer Film | An blow-extrudable film that ensures a reclosing ability after a first opening consists of a support layer on which a connecting layer and an overlying cover layer are arranged. The connecting layer essentially consists of a pressure sensitive hot melt adhesive. Both the support layer and the cover layer are essentially composed of polyethylene. The support layer may e.g. be made of low density and/or high density polyethylene (LD-PE respectively HD-PE). The cover layer consists of up to 100% LLD-PE (linear low density polyethylene) or of a blend of LLD-PE and polyethylene. Due to the LLD-PE content, the cover layer has a higher adhesion on the connecting layer than the support layer. In this manner it is ensured that in the first opening process, during which a portion of the support layer is separated, the connecting layer remains on the cover layer. Pressing the separated portion onto the connecting layer restores the bond between the separated portion and the film and recloses a container that is sealed by the film. | Food packages are often composed of a lower portion, e.g. in the form of a tray, that is covered with a film and welded together with the film at its edges to form an airtight package. Compound film of the prior art is unsuitable as a closure film for food packages due to its compositions, insufficient stability and excessive resilience. When the package is opened, the sealing layer of the compound film is detached in the sealing zone, thereby causing a cohesive failure of the hot melt.there is also a risk for the hot melt to be exposed during the filling operation due to lesions of the surface and thus enters in direct contact with the foods. | This is achieved by a multilayer film where in connecting layer is essentially composed of a pressure sensitive hot melt adhesive,Where in the cover layer and the support layer are essentially composed of polyethylene |

Interactive Taxonomy

Click on the Nodes to expand or collapse them

Click on the Red Arrow adjacent to the node name to access the Dashboard for that particular node

Click on any node and drag to move the taxonomy within the display field

Dashboard

A sample Dashboard with categorized sample patents can be accessed here.

Manufacturers and distributors

- Please find a list of Pressure sensitive adhesive(PSA) manufacturers and distributors here. The PSA's produced and distributed by these companies are used for food packaging and other applications.

Key Opinion Leaders

Listed below are few experts in Pressure sensitive adhesive in Food packaging industries.

| Sr.No | Name | Educational Qualification | Present company | Present position in company | Expertise | Experience | Image |

| 1 | Jenice Evers | 1.University of Saint Thomas - School of Business,MBA , Manufacturing Systems , 1991 — 2001 2.University of Minnesota-Twin Cities,BS , Chemical Engineering - Minor in Biology , 1982 — 1985 |

Scholle Corporation | Quality Systems Manager | Product development experience in medical adhesive and wound care products, consumer products, food packaging, and durable goods. Class I and II medical device experience.Technology experience in coated and extruded polymer materials such as pressure sensitive adhesives, coated materials, optical films, and multilayer extruded films. | 22 years | |

| 2 | Dr. Timothy B. Jensen | 1.B.S. from the University of Minnesota , Chemical Engineering 2.Ph.D. from Princeton University, Chemical Engineering |

3M Masking and Packaging Systems | Not Available | Business consultant for pressure sensitive adhesives (PSA).Areas of expertise and interest are:- packaging, tape products, regulatory and environmental issues, standards and specification development | Not Available | |

| 3 | Joseph H. Groeger | 1.B.S. Mechanical Engineering and Materials Science,University of Connecticut 2.M.S Metallurgy, University of Connecticut 3.PhD Materials Science’ University of Connecticut |

Mantis Associates Inc. | President | Industrial Consultant | 25 years | |

| 4 | Barry Werner Sanel | 1.Bachelor of Science, Computer Science/Graphic Arts 2.Associate of Arts, General Studies |

Barry Sanel Packaging Advisors | Independent Packaging Consultant | Experience developing packaging for food and beverage: ACL glass, aluminum can and bottle, PET, pressure-sensitive & cut-and-stack labels, paperboard, shrink sleeve, closure, bag, foil, Tetra Pak, direct and preprint corrugate | 17 Years |

IP Activity

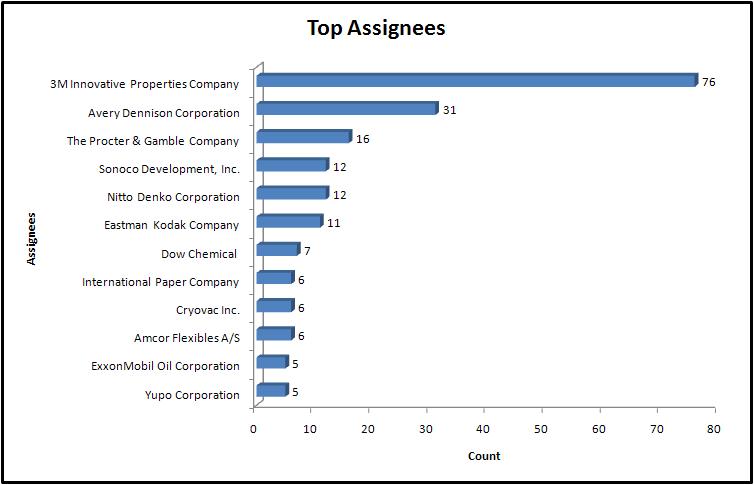

Top Assignees

As can be seen, 3M leads ahead in the list with 76 patents followed by Avery Denisson with 31 patents. These players are top in the manufacture of pressure sensitive adhesive with application in food packaging

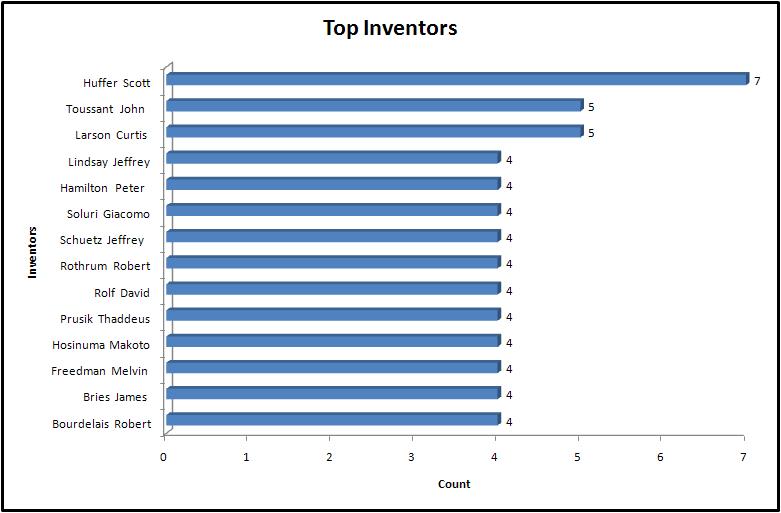

Top Inventors

Huffer Scott of Sonoco Development leads the top of the chart for Top inventors with 7 patents in the field of Pressure sensitve adhesive with application in food industry

- Note: The above values are approximate and an accurate value can be obtained after a detailed analysis of the patents obtained from the search query

Other information on PSA

Recycling issues with PSA

PSAs exact a considerable cost on the paper recycling industry, an estimated $700 million per year. Most paper recycling systems converts paper into pulp in presence of water, which is then transformed back into paper. PSAs do not dissolve in water, but rather fragment into smaller particles during the repulping process. These particles are known as stickies, get deformed under heat and pressure, making them difficult to screen or filter out of the pulp. Stickies can become lodged on papermaking and can cause damage to equipment or even in the paper. Source

| Sr. No. | "Sticky" PSA Product | Alternative Product/Procedure |

| 1 | Address Labels | 1. Print addresses directly on envelopes 2. Using glassine (cellulose) film window or filmless window envelopes, and print mailing addresses directly on the letter to show through the window. 3. Handprint addresses directly on large mailing envelopes.. |

| 2 | Sticky Notes | 1.Use scratch paper for notes and secure with paper clips. |

| 3 | Postage Stamps | 1. Use moisture-activated postage stamps 2. Postal meter that prints postage directly on envelopes or that uses moisture-activated meter tape |

| 4 | File Folder Index Labels | 1. Handprint file subjects directly on index tabs, instead of using an index label. When recycling file folders with index labels, tear off the index tab. |

| 5 | Closure Tabs | 1. Sharply folding fliers and newsletters is often sufficient to send them safely and securely through the mail. |

FDA regulations on use of adhesives in food packaging

Regulation

FDA compliance: The adhesive will be applied to food packaging, it must be compliant with USA FDA CFR 21 Section 175.105. This regulation also applies to prerssure sensitive adhesives(PSA).

Section 175.105

(a) Adhesives may be safely used as components of articles intended for use in packaging, transporting, or holding food in accordance with the following prescribed conditions:

(1) The adhesive is prepared from one or more of the optional substances named in paragraph (c) of this section, subject to any prescribed limitations.

(2) The adhesive is either separated from the food by a functional barrier or used subject to the following additional limitations:

- In dry foods:: The quantity of adhesive that contacts packaged dry food shall not exceed the limits of good manufacturing practice.

- In fatty and aqueous foods:: (i ) The quantity of adhesive that contacts packaged fatty and aqueous foods shall not exceed the trace amount at seams and at the edge exposure between packaging laminates that may occur within the limits of good manufacturing practice.

(ii ) Under normal conditions of use the packaging seams or laminates will remain firmly bonded without visible separation.

(b) To assure safe usage of adhesives, the label of the finished adhesive container shall bear the statement "food-packaging adhesive".

(c) Subject to any limitation prescribed in this section and in any other regulation promulgated under section 409 of the Act which prescribes safe conditions of use for substances that may be employed as constituents of adhesives, the optional substances used in the formulation of adhesives may include the following: (1) Substances generally recognized as safe for use in food or food packaging.

(2) Substances permitted for use in adhesives by prior sanction or approval and employed under the specific conditions of use prescribed by such sanction or approval.

(3) Flavoring substances permitted for use in food by regulations in this part, provided that such flavoring substances are volatilized from the adhesives during the packaging fabrication process.

(4) Color additives approved for use in food.

(5) Substances permitted for use in adhesives by other regulations in this subchapter and substances named in this subparagraph:Provided, however, That any substance named in this paragraph and covered by a specific regulation in this subchapter, must meet any specifications in such regulation.

- Note:Please find the complete regulation for use of FDA for food packaging here

Downloads

Click to download the analysis spreadsheets in excel format.