Pinene: An off flavor in mango juice

Contents

[hide]Objectives

The primary objective of this review was to compile experimental information and relevant literature to help researches working in the area of pinene removal, an off flavor, form mango juice.

Associated objectives were:

- To map the biological pathway of pinene synthesis in mango from the basic element available to cell such as carbohydrate or proteins.

- To find out methods from literature which can help in cutting down the synthesis of pinene in mango (or other fruits). The challenge was to ascertain physical parameters that can effect pinene synthesis in fruits such as temperature, pH, humidity, oxygen concentration and stage of ripening. These parameters can then be taken care of during farming, storage, fruit processing and juice production stages to avoid pinene production in mango. Playing with physical conditions mentioned above are far more cost effective and time saving than the usage of more complex and costly methods such as usage of recombinant DNA technology and genetic engineering, which may not always prove successful.

- To provide literature uncovering methods of pinene isolation from magno and other fruits.

- To provide other important supporting information such as chemical synthesis methods of pinene, isomers of pinene, chemical and physical properties of pinene that could be helpful from researcher's point of view.

- To give IP activity in the area of pinene which may involve methods patented to synthesize pinene in labs, usage of pinene to synthesize other important compounds etc.

- Finally, based on our extensive analysis we proposed a way which can turn out to be a cost effective measure to curb pinene production in mango.

Overview

The chemical compound pinene is a bicyclic terpene known as a monoterpene. There are two structural isomers found in nature: α-pinene and β-pinene. As the name suggests, both forms are important constituents of pine resin; they are also found in the resins of many other conifers, and more widely in other plants. Both are also used by many insects in their chemical communication system. e-soruce 1

Alpha-Pinene

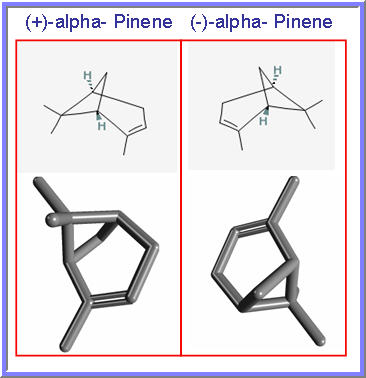

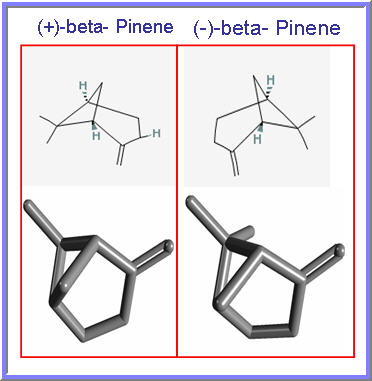

Alpha –Pinene (α-pinene) is an organic compound of the terpene class, one of two isomers of pinene. It is an alkene and it contains a reactive four-membered ring. It is found in the oils of many species of many coniferous trees, notably the pine. It is also found in the essential oil of rosemary (Rosmarinus officinalis). Both enantiomers (shown below) are known in nature; 1S, 5S- or (−)-α-pinene is more common in European pines, whereas the 1R,5R- or (+)-α-isomer is more common in North America. The racemic mixture is present in some oils such as eucalyptus oil. e-source 2 In Brazil alone, the pine resin tapping activity is increasingly important, producing resin mostly for export; 100,000.00 tons were produced in 2002, a market that moved some US$ 25 millions, providing over 12,000.00 direct jobs in the countryside. Limberger et al., 2007 & e-source 3

Beta-Pinene

Beta-Pinene (β-pinene) is a colorless liquid, soluble in alcohol, but not water. It has a woody-green pine-like smell. It occurs naturally in rosemary, parsley, dill, basil, yarrow, and rose. Both enantiomers (+)-beta- Pinene and (-)-beta- Pinene are shown below. e-source 4

Important properties of pinene in juices

- Give piney aroma to juices. Bell, 2004

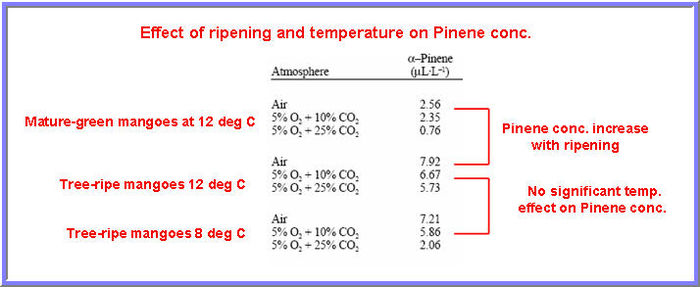

- Concentration of pinene was reported to be 2.56µL/L and 7.92µL/L in mature-green (MG) and tree-ripe (TR) mangoes respectively. Bender and Brecht, 2000

- Retention time of pinene in mango juice was reported to be 23.13 minutes. Zhang et al., 2006

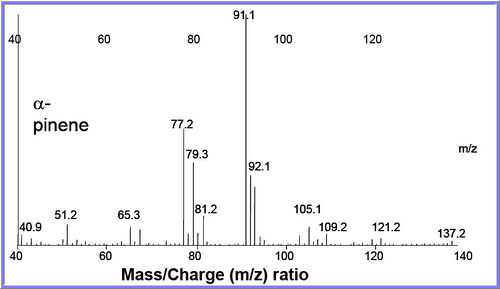

- m/z of pinene was found to be 91.1. Bell, 2004

Synthesis of pinene

Biological synthesis of pinene

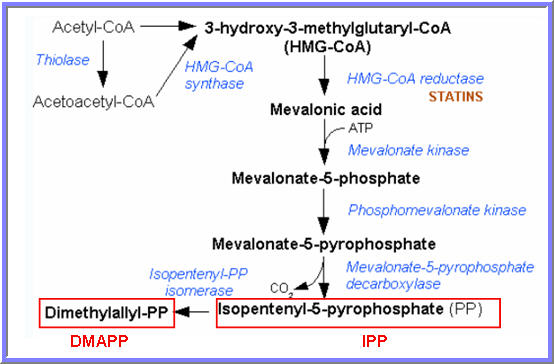

Step 1: Formation of GPP from Acetyl-CoA

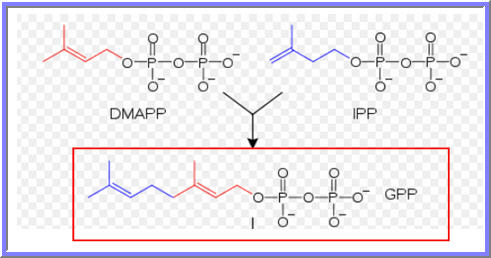

The mevalonate pathway or HMG-CoA reductase pathway or mevalonate-dependent (MAD) route or isoprenoid pathway, is an important cellular metabolic pathway present in all higher eukaryotes and many bacteria. It is important for the production of dimethylallyl pyrophosphate (DMAPP) and isopentenyl pyrophosphate (IPP), which serve as the basis for the biosynthesis of molecules used in processes as diverse as terpenoid synthesis. (Figure below e-source 5

Geranyl pyrophosphate is an intermediate in the HMG-CoA reductase pathway used by organisms in the biosynthesis of farnesyl pyrophosphate, geranylgeranyl pyrophosphate, terpenes and terpenoids and is formed by the reaction between DMAPP and IPP. (Figure below). e-source 6

Step 2: Synthesis of pinene from GPP

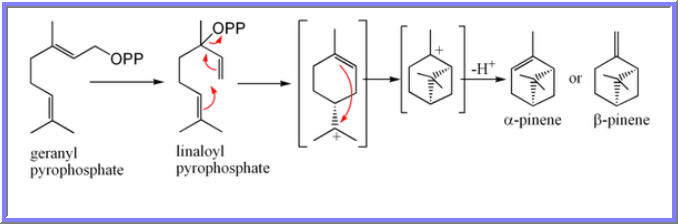

α-Pinene and β-pinene are both produced from geranyl pyrophosphate, via cyclisation of linaloyl pyrophosphate followed by loss of a proton from the carbocation equivalent. e-source

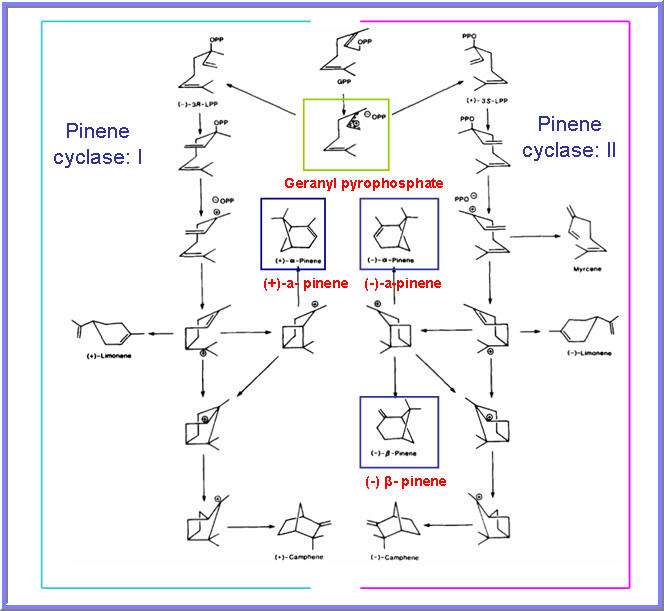

Role of pinene cyclase I and II in conversion of GPP to α & β pinene

The soluble enzyme preparations from tissue of Saluia officinalis leaves were shown to catalyze the divalent cation dependent cyclization of the acyclic C10 precursor [l-3H] GPP1 to (+/-)-7- H] α -pinene and (-)-[7-3H] β – pinene. The co-occurrence in the same species of the (+)- and (-)- modification is fairly common among the cyclic monoterpenes but rare among the higher terpenes, and it is generally assumed that such enantiomers are synthesized independently via stereochemically distinct routes.

On fractionation by gel filtration on Sephadex G-150 has shown two regions of enzymatic activity termed geranyl pyroph0sphate: Pinene cyclase I (Mr = 96,000), which catalyzed the conversion of geranyl pyrophosphate to the bicyclic olefin (+)-a-pinene, and geranyl pyrophosphate: pinene cyclase II (Mr = 55,000), which transformed the acyclic precursor to (-)-a-pinene and (-) β- pinene. Gambliel and Croteaug et al., 1984

Effect of ripening and temperature on pinene synthesis in mangoes

The concentrations of all four of the terpene volatiles including alpha-pinene were influenced by initial ripeness stage, with mature-green (MG) fruit from all atmosphere treatments stored at 12 °C having lower concentrations than did tree-ripe (TR) mangoes stored at the same temperature (figure below). However, there was no significant temperature effect on the levels of the terpene volatile, alpha-pinene, for TR mangoes stored at 8 or 12 °C. This shows that the concentration of pinene in mangoes remains nearly unaffected with change in temperature from 8 deg C to 12 deg C but increase significantly with ripening of fruit. Bender and Brecht, 2000

Isolation and analysis of pinene

Aroma characteristics of Chinese mango cultivars by GC/MS

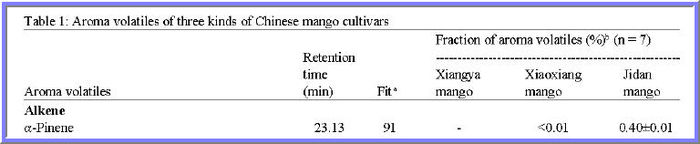

The figure below shows aroma volatile properties of pinene in three kinds of Chinese mango cultivars Xiangya, Xiaoniang, Jidan mangoes. Fit value was referred to what degree the target spectrum matched the standard spectrum in theNIST library (100 relates to a perfect fit). Area of the peak of an aroma volatile (%) was calculated by dividing Area of the peak of an aroma volatile by total area of all aroma volatile. Zhang et al., 2006

Retention characteristics of pinene in grapefruit juice

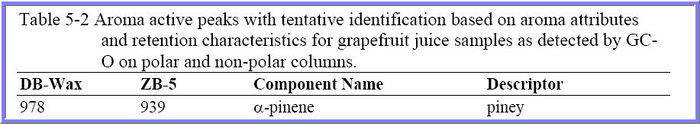

Aroma active peaks with tentative identification based on aroma attributes and retention characteristics for grapefruit juice samples as detected by GC-O on polar and non-polar columns for pinene is shown in the figure below.

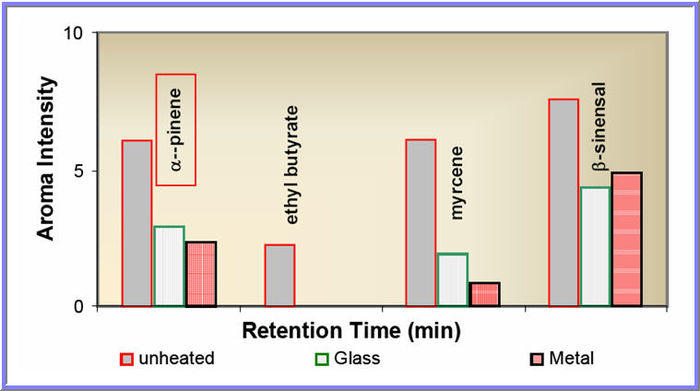

Three aroma active compounds, α-pinene, myrcene and β-sinensal, exhibited greater aroma intensities in the unheated reconstituted juice compared to that of the two heated juice samples. Pinene is a low boiling point compound, which has higher aroma intensity in the unheated reconstituted juice compared to the two heated juice treatments. In both heated samples, the response for α-pinene was less than 45% that of the unheated reconstituted juice. Bell, 2004

Chemical and physical properties of pinene

| Vanillin Comprehensive Information Table | ||

| 1 | Molecular Weight | 136.23404 [g/mol] |

| 2 | Molecular Formula | C10H16 |

| 3 | XLogP3-AA | 2.8 |

| 4 | H-Bond Donor | 0 |

| 5 | H-Bond Acceptor | 0 |

| 6 | Rotatable Bond Count | 0 |

| 7 | Exact Mass | 136.125201 |

| 8 | MonoIsotopic Mass | 136.125201 |

| 9 | Topological Polar Surface Area | 0 |

| 10 | Heavy Atom Count | 10 |

| 11 | Formal Charge | 0 |

| 12 | Complexity | 186 |

| 13 | Isotope Atom Count | 0 |

| 14 | Defined Atom StereoCenter Count | 2 |

| 15 | Undefined Atom StereoCenter Count | 0 |

| 16 | Defined Bond StereoCenter Count | 0 |

| 17 | Undefined Bond StereoCenter Count | 0 |

| 18 | Covalently-Bonded Unit Count | 1 |

Patents on pinene

Some of the patents involving synthesis of pinene or compounds from pinene are shown below.

| Sr. No. | Patent/Publication No. | Title | Abstract | Assignee / Applicant |

| 1 | US3676504A | PREPARATION OF A TEREPENE ALCOHOL | Synthesis of terpinene-4-ol from terpinolene. | R. J. Reynolds Tobacco Company |

| 2 | GB1033170A | Isomerisation of -pinene | b -Pinene is obtained by catalytic isomerization of a -pinene containing less than the equilibrium amount of b -pinene under neutral to basic conditions at 20 DEG to 300 DEG C., using as catalyst Pd, Pt, Ni, Ru, Rh, Os, Ir, alkali metal, sulphur, iodine, alkali metal alkoxide having 2 or more carbon atoms, palladium chloride or platinum oxide. The catalyst may be supported on a non-acidic carrier and contact times of 0.05 second to 2 minutes are used. b -Pinene is preferably recovered by distillation and in one embodiment make up feed is introduced into a fractionation column in which a -pinene is separated overhead for isomerization from b -pinene product and to which is also fed the isomerizate. | GLIDDEN CO |

| 3 | WO2008044640A1 | & 946;-PINENE POLYMER AND PROCESS FOR PRODUCTION THEREOF | The invention provides a & 946;-pinene polymer which is excellent in heat resistance in spite of its having thermoplasticity and exerts excellent strength without impair in the inherent characteristics such as small specific gravity and excellent transparency. An objective & 946;-pinene polymer which has a weight-average molecular weight of 90,000 to 1,000,000 and a glass transition temperature of 80°C or above can be obtained by polymerizing & 946;-pinene in the presence of a bifunctional vinyl compound. | align = "center" Yasuhara Chemical Co., Ltd. | KURARAY Co., Ltd. | National University Corporation Nagoya University | KAMIGAITO, Masami | SATOH, Kotaro | SUGIYAMA, Hiroko |

| 4 | GB190202129A | Improvements in the Production of Derivatives of Pinene. | 2129. Mills, C. K., [Ampere Electro-Chemical Co.]. Jan. 27. Dipentene and camphor.-Relates to improvements in the process described in Specification No. 14,754, A.D. 1900, and consists chiefly in an adaptation of the process for the purpose of separately collecting the dipentene which is produced by it. Rectified and dehydrated turpentine is heated with anhydrous oxalic acid at 120‹-130‹ C., whereby a mixture of dipentene with smaller quantities of pinyl formate and oxalate, free camphor, borneol oxalate and formate, and higher polymerization products of pinene, is produced. The mass is washed with water to remove free acid, enough alkali is added to saponify the borneol oxalate and formate, and the mixture is distilled. The first portion of the distillate, which consists mainly of dipentene, is collected separately. The remainder of the distillate, consisting of camphor, borneol, and oils, is frozen, treated centrifugally, and washed with cold water to separate the oils, and the residue is oxidized with potassium bichromate and sulphuric acid to convert the borneol into camphor. The camphor produced is centrifugalled, washed, dried, and sublimed with lime. | None |

| 5 | JP8034821A | PRODUCTION OF ALPHA-PINENE RESIN HAVING HIGH SOFTENING POINT | PURPOSE: To produce an & 945;-pinene resin having a softening point as high as 140°C or above in yields as high as 80% or above. CONSTITUTION: This production process is one for producing an & 945;-pinene resin by polymerizing & 945;-pinene in the presence of a catalyst system comprising aluminum chloride and antimony chloride in an inert solvent, which process comprises separately adding a mixture prepared by adding 0.5-1.5 pts. wt. antimony chloride to an inert solvent and & 945;-pinene to a dispersion prepared by dispersing 1 pt.wt. aluminum chloride within the scope in which the total amount of the catalyst system used is 1-2wt.% based on the & 945;-pinene to polymerize the & 945;-pinene and further adding aluminum chloride and antimony chloride to the reaction system to polymerize the & 945;-pinene.COPYRIGHT: (C)1996,JPO&Japio | ARAKAWA CHEM IND CO LTD |

- To download the complete patent sheet click here

Conclusion

Pinene, a monoterpene is known to exist as an off flavor in mango juice. Pinene exists in two structural isomers in nature, α-pinene and β-pinene. Biologically, synthesis of pinene can be summarized in two steps. In step one, acetyl CoA results in formation of dimethylallyl pyrophosphate (DMAPP) and isopentenyl pyrophosphate (IPP) via HMG CoA reductase pathway. Further, DMAPP and IPP combines to form Geranyl pyrophosphate (GPP). In step two, GPP undegoes cyclization to give pinene. Pinene cyclase I and II are the two enzymes responsible for conversion of GPP to (+)-a-pinene and (-)-a-pinene, (-) β- pinene, respectively. Production of pinene was found to be increased in mangoes as the ripen during fruit maturation. Change in temperature from 8 deg C to 12 deg C was shown to have no significant impact on pinene production in mangoes. On the other hand, aroma intensity of pinene was found to be more in unheated samples than heated samples. From these studies it can be hypothesized that to curtail the formation of pinene, an off flavor in mango juice, it is important to consider the ripening stage of fruit. Since, there was no significant change in pinene concentration with increase in tempearture, heat treatment can prove helpful in decreasing the aroma intensity of pinene in mango juice. The review has further covered isolation and analysis of pinene by GC/MS and GC-O lab techniques, from mango and grape fruits sufficiently. A comprehensive information table on various important chemical and physical properties of pinene has been presented. The IP activity in the field of pinene synthesis and application of pinene for synthesis of several other compounds have also been summarized towards the end.

References

- Bell WAM. 2004. Examination of aroma volatiles formed from thermal processing of florida reconstituted grapefruit juice. Bell, 2004

- Bender RJ and Brecht JK. 2000. Aroma volatiles of mature-green and tree-ripe ‘Tommy Atkins’ mangoes after controlled atmosphere vs. air storage. HORTSCIENCE 35: 684–686. Bender and Brecht, 2000

- Gambliel H and Croteaug R. 1984. Pinene Cyclases I and II. THE JOURNAOLF BIOLOGICAL CHEMISTRY. 259: 740-748. Gambliel and Croteaug et al., 1984

- Limberger RP, Aleixo AM, Fett-Neto AG, Henriques AT. 2007. Bioconversion of (+)- and (-)-alpha-pinene to (+)- and (-)-verbenone by plant cell cultures of Psychotria brachyceras and Rauvolfia sellowii. Electronic Journal of Biotechnology. DOI: 10.2225/vol10-issue4-fulltext-8. Limberger et al., 2007

- Zhang ZM, Zeng DDand Li GK. 2006. The Study of the Aroma Characteristics of Chinese Mango Cultivars by GC/MS with Solid Phase Microextraction. Journal of Plant Sciences 1: 98-105. Zhang et al., 2006