Brief History of Wind Energy

Although the use of wind power started around 5000 BC, but electric power generation through wind energy started in 18th century and increasing drastically in 19th and 20th centuries. A brief view on developments on wind power sector are listed below.

- 1887 : Prof. James Blyth of Scotland used windmills for generating electricity.

- 1888 : Charles Brush developed the first wind-powered turbine that generated electricity in the United States based on emulated James Blyth work.

- 1927 : Joe Jacobs and Marcellus Jacobs improved the wind turbine generator for use in farms.

- 1931 : development of Darrieus wind turbine. It is a vertical axis turbine that rotates with wind from any direction.

- 1941: Largest mega watt range wind turbine was connected to the local electrical distribution system on the mountain known as Grandpa's Knob in Castleton, Vermont, USA.

- 1971: Denmark installed the first offshore wind farms

- 1990s: More than 2200 MW capacity of wind turbines are installed in california.

- 2003: the largest offshore wind farm North Hoyle was built in the United Kingdom.

- 2003-2010: Research is going is on wind turbines in blades structures, generators, operation and protection, efficiency of wind turbines.

Source: Wind Energy

The total installed wind power capacity from 2001 to 2010 is shown in fig. 1. All wind turbines installed by the end of year 2009 worldwide are generating 340 TWh per annum.

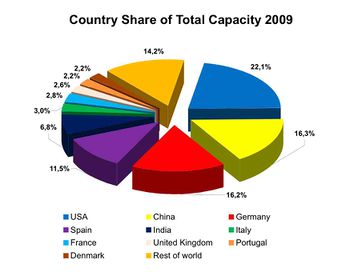

The country wise share of wind energy by the end of year 2009 is shown in fig. 2.

Working Principle of Wind Turbine

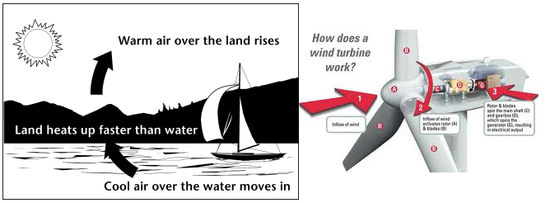

Wind is air in motion. It is a form of solar energy. Solar radiation heats every part of the Earth’s surface unevenly due to irregularities and rotation of earth. The flow of wind patterns are modified by the earth's terrain, bodies of water, and vegetative cover. When air moves, causing wind, it has kinetic energy. The kinetic energy of wind can be captured by a wind turbine and converted to other forms of energy such as electricity or mechanical power.

Sources:Wind Energy Basics,How Wind Turbines Work

Horizontal Axis and Vertical Axis Wind Turbines

Wind turbines are mainly classified into two types based on the axis in which turbine rotates. They are Horizontal axis wind turbine(HAWT) and vertical axis wind turbine (VAWT). The table below presented, describes the advantages and disadvantages of HAWT's and VAWT's.

| Horizontal axis wind turbines | Vertical axis wind turbines |

Fig 4(a) Horizontal axis wind turbine |

Fig 4(b)Vertical axis wind turbine |

Horizontal Axis Wind Turbines

All grid-connected commercial wind turbines today are built with a horizontal axis type rotor which is installed on top of a tower. Most horizontal axis turbines built today are two- or three-bladed, although some have fewer or more blades. The purpose of the rotor is to convert the linear motion of the wind into rotational energy that can be used to drive a generator. Most of the systems have a gearbox, which turns the slow rotation of the blades into a quicker rotation that is more suitable to drive an electrical generator.

Click on the link below to see detailed description about horizontal axis wind turbines.

Different Types and Parts of a Horizontal Axis Wind Turbines

Electrical Generating Systems

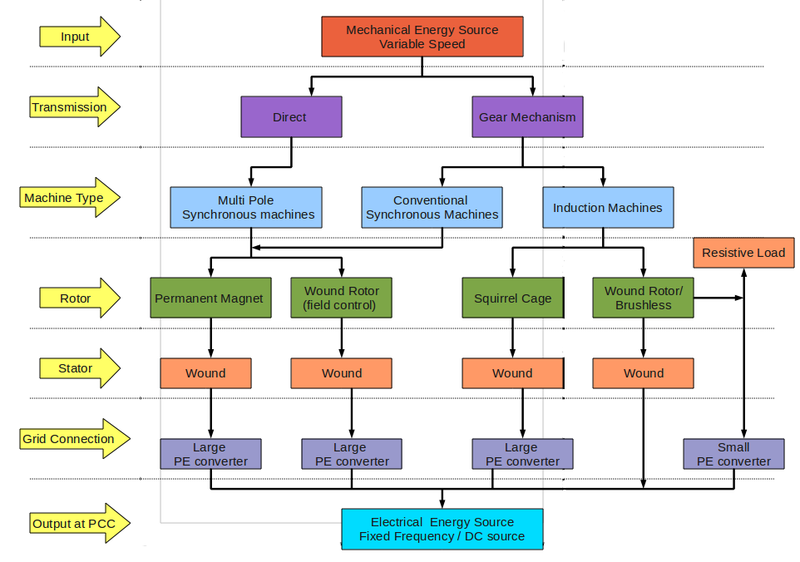

The various types of electrical generating systems used in wind energy systems are shown in figure.

Source:Wind Turbine Generators

The most commonly used generator systems applied in wind turbines are are explained below.

| Fixed speed generating systems | Variable speed generating systems | Doubly fed induction generator | |

| Structure | |||

| Machines | SQIG | PMSG/WRSG/WRIG | DFIG |

| Advantages | * Simple and low cost

* Low maintanace |

* Complete control of real and reactive powers

* High energy efficiency |

* Reduced capacity converter

* Decoupled control of active and reactive power flow * Smooth grid connection |

| Drawbacks | * No control on real and reactive power

* Less optimum power extraction capability * Poor power factor * High mechanical stress on turbine mechanical components |

* Additional cost of power electronics

* Limited fault ride through capability |

* Regular maintenance of slip ring and gearbox

* Limited fault ride-through capability |

Source:Inside wind turbines

In this report, a comprehensive analysis of patent and non-patent literature is done with a focus on Doubly-fed induction generator systems.

Wind Turbine Control Systems

As the wind turbines increases in size and power, control systems plays a major role to operate wind turbines in safe region and also to improve efficiency and quality of power conversion. The main objectives of wind turbine control systems is

- Energy capture : Operating the wind turbine to extract maximum amount of energy considering safe restrictions like rated power, rated speed, cut-out wind speed etc.,

- Mechanical loads: protecting the systems from transient loads.

- Power quality: Conditioning the generated power with grid interconnection standards.

The various control techniques used in wind turbines are shown in table below

| Control System | Pitch contol | Yaw control | Stall control | Generator torque control |

| Description | A method of controlling the speed of a wind turbine by varying the orientation, or pitch, of the blades, and thereby altering its aerodynamics and efficiency.

Fig 16(a) Pitch control Source:Blade Pitch Control |

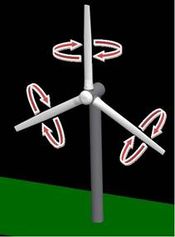

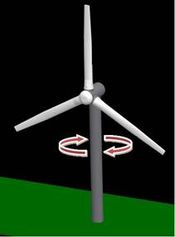

The rotation of horizontal axis wind turbine around its tower to orient the turbine in upwind or down wind direction.

Fig 16(b) Yaw control Source:Wind Turbine Control Methods |

Stall control works by increasing the angle at which the relative wind strikes the blades (angle of attack). As the wind speed increases drag force on the blade increase and lift force gets reduces, thus finally reduces the speed of turbine.A fully stalled turbine blade, when stopped, has the flat side of the blade facing directly into the wind. Compare with furling.

Source:Stall-control basics |

As the aerodynamic torque control changes, rotor speed changes. it changes the output power frequency. A frequency converter is connected in between generator and the network to maintain generator power constant.

SourceWind Energy Control |

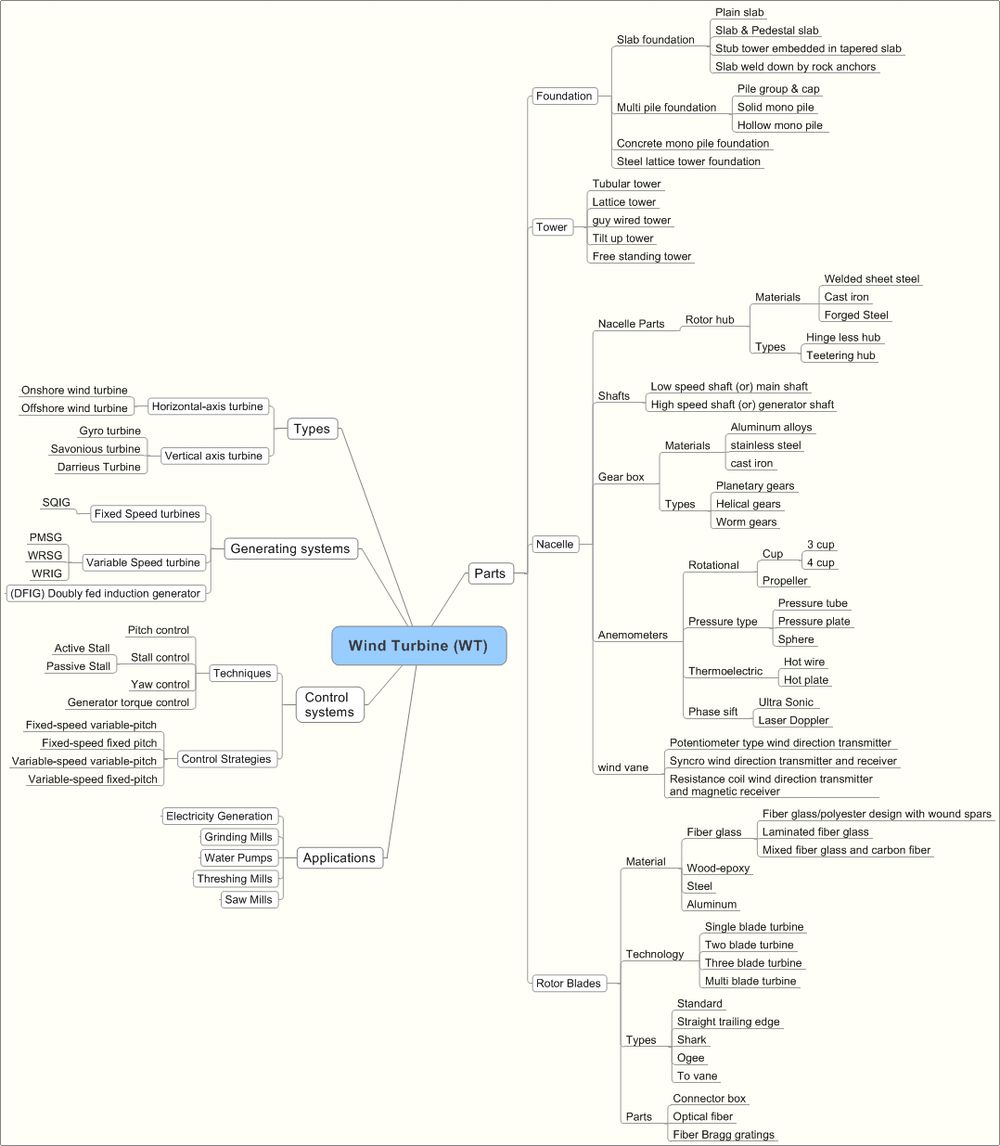

Taxonomy for Wind Turbines

A detailed taxonomy is presented which covers Parts, Types, Control Systems, Generating systems and Applications of wind turbines.

IPC Classifications

A majority of patents describing wind turbines or wind energy are classified in the following IPC classifications.

| S.NO | IPC Classification | Description |

| 1 | F03D | WIND MOTORS |

| 2 | F16C | SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OF CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS |

| 3 | F16H | GEARING |

| 4 | F03B | MACHINES OR ENGINES FOR LIQUIDS |

| 5 | H02K | DYNAMO-ELECTRIC MACHINES |

| 6 | H02P | CONTROL OR REGULATION OF ELECTRIC MOTORS, GENERATORS, OR DYNAMO-ELECTRIC CONVERTERS; CONTROLLING TRANSFORMERS, REACTORS OR CHOKE COILS |

| 7 | H02M | APPARATUS FOR CONVERSION BETWEEN AC AND AC, BETWEEN AC AND DC, OR BETWEEN DC AND DC, AND FOR USE WITH MAINS OR SIMILAR POWER SUPPLY SYSTEMS; CONVERSION OF DC OR AC INPUT POWER INTO SURGE OUTPUT POWER; CONTROL OR REGULATION |

| 8 | H02J | CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY |

| 9 | G06F | ELECTRIC DIGITAL DATA PROCESSING |

| 10 | G05F | SYSTEMS FOR REGULATING ELECTRIC OR MAGNETIC VARIABLES |

| 11 | H02H | EMERGENCY PROTECTIVE CIRCUIT ARRANGEMENTS |

Major Players

Major players in the Wind Energy sector include: General Electric, Vestas Wind Systems, Siemens AG, Mitsubishi Ltd, REPower Systems AG, Gamesa Innovation & Technology, Enercon, Nordex, Suzlon and Sinovel Wind Group Co. Ltd.

Like this report?

This is only a sample report with brief analysis

Dolcera can provide a comprehensive report customized to your needs

| |