Rationale

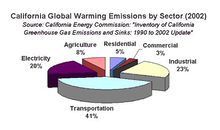

- Automobiles are a source of considerable pollution at the global level, including a significant fraction of the total greenhouse gas emissions.

- On July 22, 2002 California Governor Gray Davis signed into law AB 1493 (commonly known as the "Pavley law") — precedent-setting legislation to reduce global warming pollution from motor vehicles.

- This bill directs the California Air Resources Board (CARB) to develop and adopt regulations that achieve the maximum feasible and cost-effective reduction of greenhouse gas emissions (GHG) from passenger cars and light trucks sold in California.

New Developments

The new millennium is bringing a millennial change to the family car. A few years back, the key concerns were:

- Pollution,

- Nagging worries about global warming, and

- Oil shortages.

These concerns led to the development of Electric Vehicle (EV’s) powered by batteries. But current battery technology does not provide EV's with a range that is acceptable to consumers.

Limitations of EV’s:

- An average commute to work is around 40 miles.

- EV's have a range of 80-100 miles using advanced battery technology.

- While batteries need frequent recharging, they are not the only way to power an electric car.

Hybrid Electric Vehicle (HEV)

The Hybrid Electric Vehicle (HEV) is just the first step in reducing the environmental impacts of automobile use without losing comfort, performance, storage room and extended driving range.

Advantages of HEV’s:

- The HEV contains parts of both gasoline and electric vehicles in an attempt to get the best of both worlds.

- It is able to operate nearly twice as efficiently as traditional internal combustion vehicles.

- It has equivalent power, range, cost and safety of a conventional vehicle while reducing fuel costs and harmful emissions.

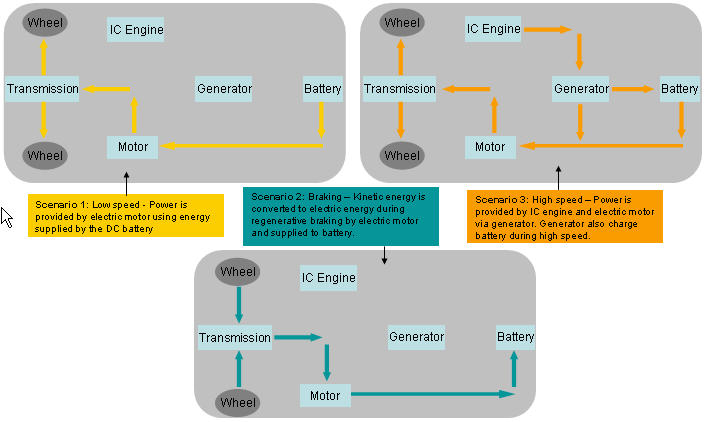

- The battery is continuously recharged by a motor/generator driven by the Internal Combustion Engine (ICE) or by regenerative braking.

Components of the HEV Battery System

The battery in an HEV is the energy storage device for the electric motor. Unlike the gasoline in the fuel tank, which can only power the gasoline engine, the electric motor in a hybrid car can put energy into the battery as well as draw energy from it.

- Battery: Two or more electrochemical energy cells connected together to provide electrical energy.

- Generator: The generator is similar to an electric motor, but it acts only to produce electrical power.

- Electric motor: Advanced electronics allow it to act as a motor as well as a generator. For example, when it needs to, it can draw energy from the batteries to accelerate the car. But acting as a generator, it can slow the car down and return energy to the batteries.

- SOC: The State of Charge of a battery is its available capacity expressed as a percentage of its rated capacity

HEV battery system design parameters

Factors affecting battery performance:

- Temperature: Battery performance is highly dependent on temperature. Each type of battery works best within a limited range of temperatures.

- Battery age/Shelf life: Corrosion is the main culprit behind decreased performance in lead acid type batteries with age.

- Depth of discharge: Batteries are able to maintain their performance longer when they are not deeply discharged regularly.

Design parameters:

- How much space is available for the batteries?

- How much can they weigh?

- What is the desired range?

- What is the weight of the vehicle?

- What is the targeted vehicle cost?

- How will the batteries be recharged and

- What kind of drive system requirements is needed?

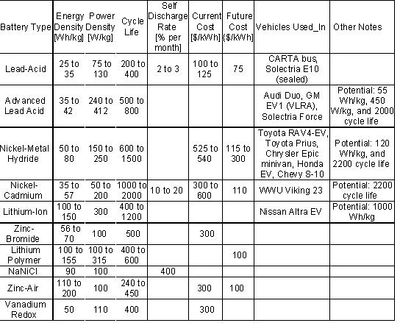

These questions are necessary because of the variety of battery types available and the differences between them. The chart below lists the characteristics of the most common types of batteries. (Source [1])

Comparison of top 3 batteries used in HEVs

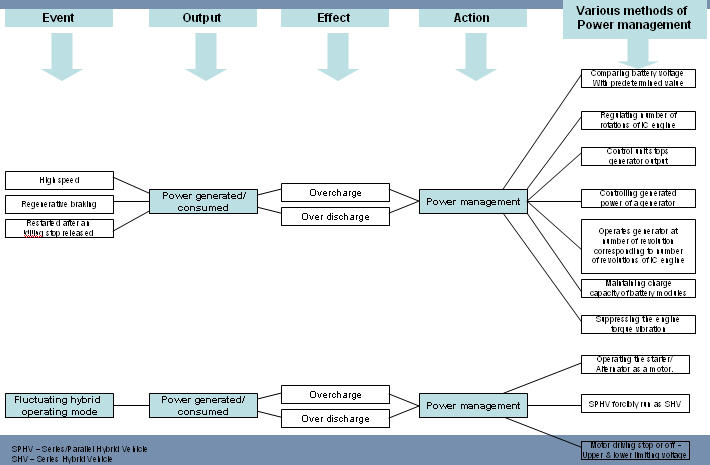

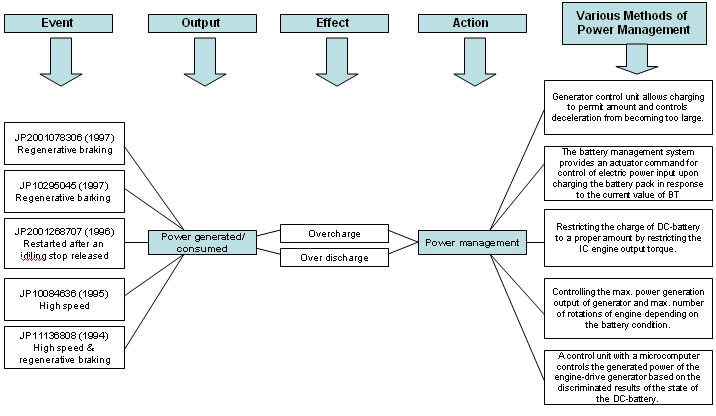

During recharging, it is important to maintain the balance of battery. The balance of battery is maintained by controlling battery from overcharging and over discharging.

The battery is controlled by defining State of Charge (SOC) of the battery:

- Upper limit value – overcharge and

- Lower limit value – over discharge

When overcharge is detected, power generation is controlled/cut-off and when over discharge is detected, power supply to electric motor is stopped. Detection is achieved by appropriate sensors. This report investigates various procedures available/adopted by various assignees in order to maintain balanced battery pack by avoiding overcharge and/or over discharge.

Lead Acid Advanced Lead Acid Nickel-Metal Hydride Low cost Longer lifecycle than conventional lead acid High cost Low energy density Valve regulated lead/acid (VRLA) batteries showing promise Higher energy density than lead acid; not as susceptible to heat Longer recharging time (6-8 hours) Shorter recharging time Only fair cycle life Can be ruined by completely discharging them

HEV battery system concerns

The ultimate goal of HEV can only be achieved with the balance battery pack since the main source of energy is batteries and recharging is carried out on board.

Advantages of balance battery pack:

- Balancing of battery SOC’s increases battery life

- Automated balancing circuitry will decrease overcharging (and gassing) and decrease manual maintenance.

This, in turn, provides:

- Equivalent power range at low cost as conventional vehicle while reducing fuel costs and harmful emissions.

- Twice the travel distance of a conventional vehicle on the same amount of energy.

Goal

This report attempts to summarize various approaches involved in maintaining battery balance. We have selected a few patents, and will show:

- IP activity over the years

- Competitors

- Competitor and Market Landscape

- Technology map

- Technology approaches

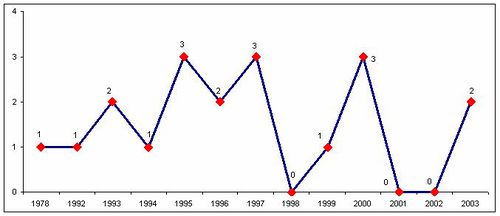

IP activity over the years

Assignee wise IP activity

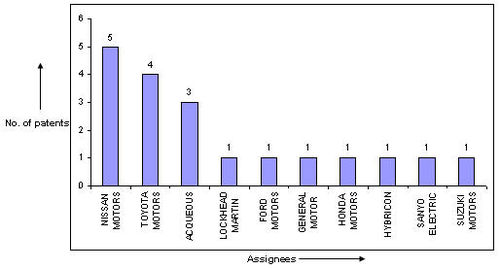

Companies with most HEV battery patents are arranged in decreasing order in below graph. Top three players are Nissan motors with (5) patent records to its credit, followed by Toyota with (4) and Acqueous (3).

Competitor and Market Landscape

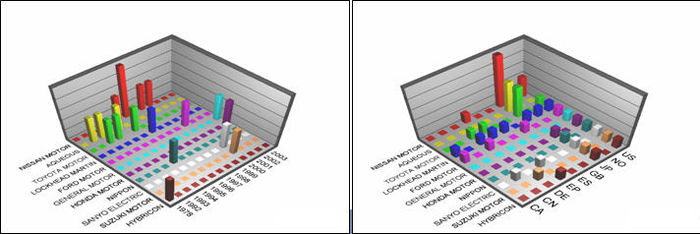

The below left graph displays assignee wise IP activity over years, according to the present data the very first patent pertaining to HEV battery charging system was filed by HYBRICON in 1978 but not in the race anymore. Though NISSAN, AQUEOUS and TOYOTA seems to be ahead in acquiring max. number of patent to their credits, but not active since 2000. GM and HONDA have bagged a single-single patent of same age in 2003.

The below right graph displays market (countries) eyed by various competitors. The hot market place for most competitors is Japan (17) followed by United States (11) and Germany (04). According to the present data Nissan seems to be having strong presence in Japan market than rest with 5 patents protected, followed by Aqueous and Toyota.

We will look in to their technologies in competitor approaches section coming latter in the report.

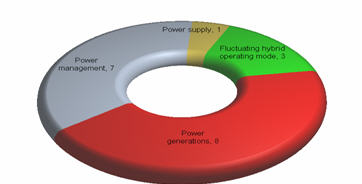

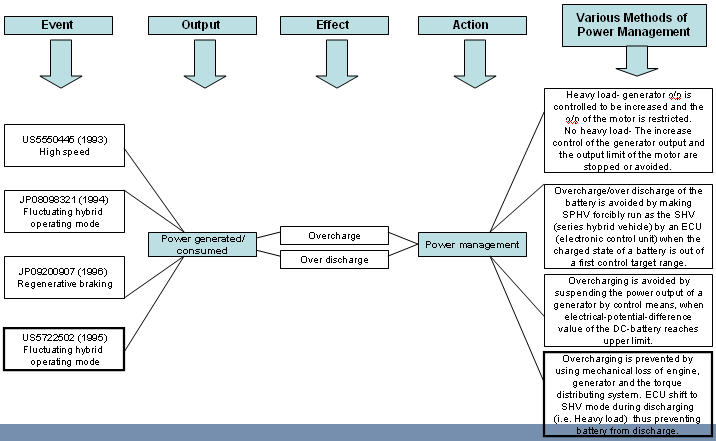

Distribution of patents based on Technology focus

The above pie chart displaying various factors has effect on battery charge and discharge. The numbers indicating the distribution of patents in that area are from selected list of patents. The distribution of patents is based on technology focused in the patent.

- Power generation: Technologies disclosed in patents for modes of power generation in HEV for charging the battery and ways of handling them.

- Power management: Technologies disclosed in patents for managing the battery balance during power generating and/or consuming.

- Fluctuating HEV operating mode: Technologies disclosed in patents for managing battery balance during fluctuating operating modes, especially in composite HEV.

- Power supply: Technology disclosed in patent for starting engine with auxiliary battery current when main battery current is not sufficient to start engine

IPMap

Clustering - Technology focus

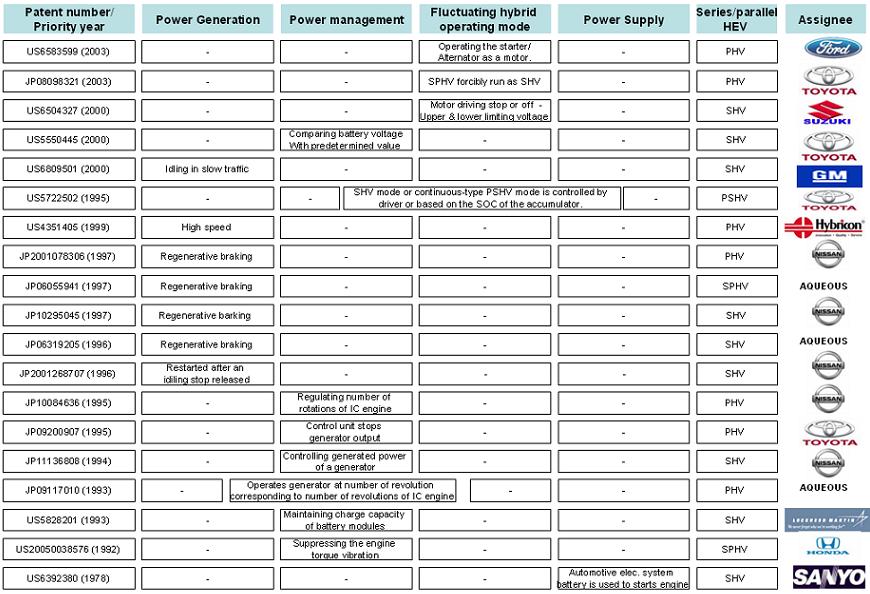

Technology approach

Competitor's

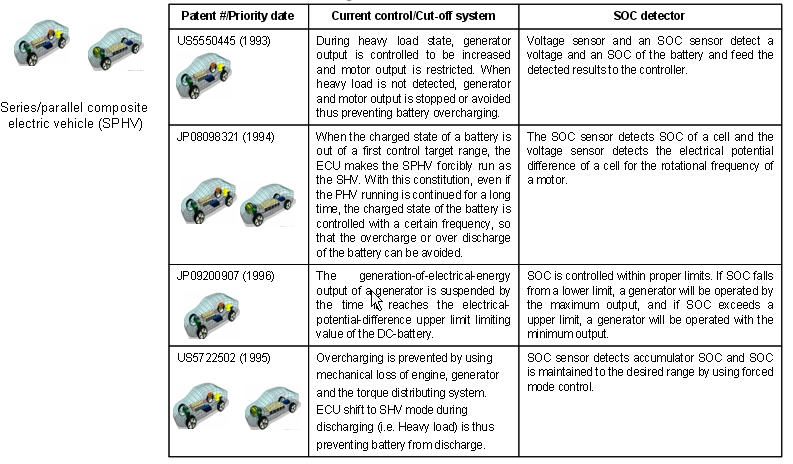

In technology approach patent and non-patent literature is used to extract information about the technology profile of various assignees such as

- Years in this activity

- Type of batteries used

- Battery charging system

- Type of HEV (Series (SHV)/Parallel (PHV)/Composite (SPHVS))

- Technology strength based on citation analysis

- Product Vs patent identification

- Battery management solutions proposed (i.e. current control/cut-off system and SOC detection

technique)

- Scientific literature and technology news to strengthen the report, since patent activity is a slow process.

Toyota Motors

Battery type: Lead-Acid battery

Battery charging system: The charge to a DC-battery is provided by the generating power from a generator and the regeneration powerfrom the drive motor at the time of braking.

- Approach1:

- Approach2:

- Findings:

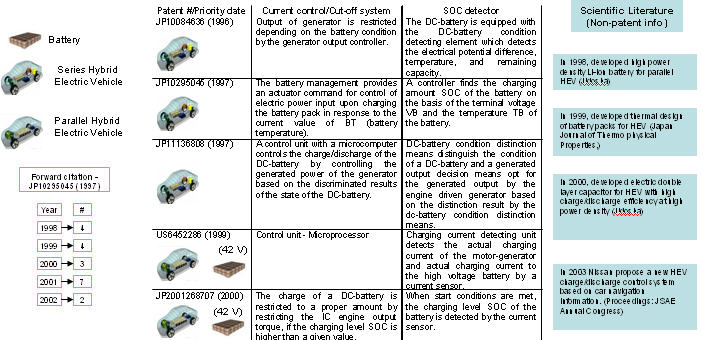

Nissan Motors

- Battery type:- Lead-acid and/or Nickel-Hydrogen battery

- Battery charging system:-

The battery is charged from the power generated by the generator and regeneration power from a motor.Electric motor functions as a generator to charge the battery when a hybrid vehicle is restarted after an idling stop released.

- Approach1:

- Approach2:

Findings:

- JP10295045 (1997):- Battery management system, received 21 forward citations from all big names in a span of 5 years and self- cited twice the same technology indicating strong technology strength and building on its own technology.

- Patent and non-patent information indicate that Nissan’s has focused much on circuit arrangements for charging or depolarizing batteries or for supplying loads from batteries (H02J 7/00).

- Jointly worked with Sony corp. (1998) developing high power density Li-ion battery for parallel HEV.

- Proposed a novel charge/discharge control system based on car navigation information.