Environment Friendly Technology to Replace Cadmium Coatings

Contents

[hide]Agenda

- Introduce and explain the benefits of the green technology developed by Pratt & Whitney.

- To find out interest of the prospects in acquiring the technology on a licensed basis from Pratt & Whitney.

About Dolcera

- Dolcera is an international services firm specializing in intellectual property and market research services. Our clientele includes several fortune 500 companies and global 100 companies. For more information please visit: www.dolcera.com

- We at Dolcera are partnering with Pratt & whitney to out-license their green technology to replace Ni-Cd coatings used for finishing purposes.

About Pratt & Whitney

- Pratt & Whitney is one of the largest aircraft engine manufacturers in the world with a sales revenue of more than $12 Bn and spends more than $250 Mn in Research & Development.

- Cutting edge R&D with over a 1000 patents.

- Has always been at the forefront of technologies for turbine, rocket, reciprocating engines, power systems, etc.

Issue at Hand

- It is very difficult to ensure complete protection of steel from corrosive environment at temperatures as high as 900°F.

- Traditionally used Ni-Cd Coatings involve use of Hexavalent chromium, cadmium and cyanides which are very toxic. Thus, making it difficult to ensure Safety of the work environment.

Cadmium qualms

- Cadmium is a toxin for both animals and plants.

- Cadmium is known to sublimate in a hard vacuum environment .The sublimation products, which are conductive, can redeposit resulting in short circuits. The sublimation products may also interfere with sensitive optics.

- Cyanide solutions used in Cadmium plating are highly Toxic.

- RoHS disallows use of cadmium in electrical equipment.

- Cadmium is subject to the spontaneous growth of Cadmium whiskers. Cadmium whiskers (like tin whiskers) grow spontaneously and are capable of causing electrical failures ranging from parametric deviations to sustained plasma arcing that can result in catastrophic short circuits.Source

Environment Friendly solution

- Environmentally friendly alternative to Ni-Cd coatings.

- Eliminates Materials of Concern from the product such as Cadmium, hexavalent chromium and Cyanides from the plating process.

- Offers equivalent or superior protection to the baseline NiCd coatings.

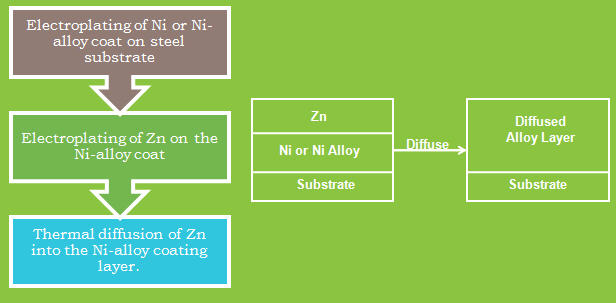

The Unique Process

Area of Application

Legal Status

Solution to the Problem

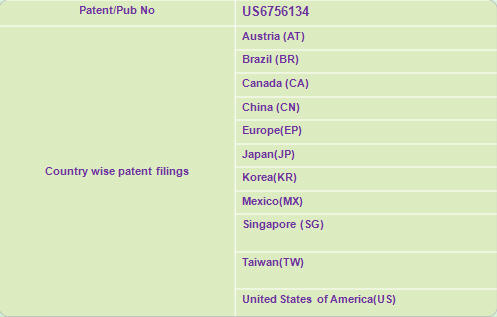

Patent Portfolio

- US6869690B1 :- This patent shows how Ni-Zn can be used to replace NI-Cd for Corrosion/Heat resistance.

- US7018486B2 :-This patent Proposes Use of environment friendly Trivalent Chromium Instead of hazardous hexavalent Chromium to enhance the anti-corrosive strength if the coating.

- US6757134B2 :-This patent explains a method of forming a thin film of high density on the substrate in order to remove any voids or grooves which might initiate corrosion.

Benefits

- Environmentally friendly alternative to NiCd.

- Eliminates Materials of Concern from the product such as Cadmium, hexavalent chromium and Cyanide from the plating process.

- Provides sacrificial Protection to the steel also as in case of cadmium.

- Offers equivalent or superior protection to the baseline NiCd coatings.

- Chemicals used in cadmium and cyanide processes are toxic to humans and are strictly regulated by local, state, and federal agencies. Replacing those processes with a non-cadmium/cyanide process reduces the volume of hazardous waste, and decreases the amount of cadmium and cyanide at the facility. The reduction of hazardous waste helps facilities meet the requirements of waste reduction under RCRA, 40 CFR 262, Appendix. It may also help facilities reduce their generator status and lessen the amount of regulations (i.e., recordkeeping, reporting, inspections, transportation, accumulation time, emergency prevention and preparedness, and emergency response) they are required to comply with under RCRA, 40 CFR 262. In addition, this technology allows facilities to eliminate cadmium and cyanide bath solutions, so there is less chance that the facility would exceed reporting thresholds for cadmium and cyanide under SARA Title III (40 CFR 300, 355, 370, and 372; and EO 12856). Both process types may require an industrial wastewater discharge permit (local issue).

Application Areas

- Coating material for steel surfaces and certain other metals like aluminum and copper which might be exposed to highly corrosive atmosphere and extremely high temperatures.

Electrical Transmission Industry

The elimination of cadmium on electrical connectors presents a unique problem not applicable to other components. Items such as fasteners, washers, etc. use cadmium primarily for its corrosion resistance and lubricity. Although these properties are equally important on electrical connectors, the connector shell materials must also provide electromagnetic and radio frequency interference (EMI/RFI) protection. This protection is gained by maintaining an electrically conductive pathway across the connector interface. Suitable alternatives for cadmium must have similar corrosion resistance, lubricity and electrical conductivity.

Fasteners

Cadmium plating is banned as far as fasteners are concerned,you need to take special permission and abide to local norms of effluent treatment for cadmium plating to be practiced.Zinc Alloy plating is of great help-Zinc/Nickel deposits from these baths, with the appropriate chromate conversion coating can withstand well over a thousand hours of Neutral Salt Fog testing.

Automotive Parts

There is an impending EU restriction on lead, cadmuim, hexavalent chrome, and mercury in vehicles.This EU restriction affects vehicles globally since car manufacturers will have to change all components if some fall under this guideline. All major auto manufacturers are now coming up with guidelines and specifications for this transition.