Biofuels database sample wiki

Contents

[hide]Introduction

To create a comprehensive database covering all published patents and scientific literature encompassing various methods for production of various bio-based fuels/alcohols.

Objectives

- There is a need to map the thousands of patents & technical literature documents in Industrial Biotechnology world to fully understand the universe of organisms, enzymes, feedstock, products and by-products and the inter-relationships between them.

- In other words, there is a need for systematic mapping pathways being explored globally.

- To solve the above problem, Dolcera has built a comprehensive database with elaborate categorization for Industrial biotechnology companies helping them map the global innovation in the bio-fuels space to the following basic variables:

- Various feedstock

- Pre-treatment methods for feedstock

- A variety of enzymes, bacteria, fungi, algae, yeast or a modified version of any of these that feed on feedstock

- Output or products that are obtained when the enzymes or bacteria or fungi or yeast feed on these feedstock.

Who is it for?

- Research and Development (R&D) leaders - If you are a scientist at a Bio-Fuels firm, this database will help you gather the best technical intelligence. It will reveal all the pathways being explored globally. It will also help you compare your inventive thinking against inventions done in the outside world. Remember, 85% of all technical intelligence is available from patents so it is not worth missing!!

- IP Attorneys - If you are an IP attorney planning IP strategy for your firm, you can compare the research strategy of your firm with all inventions out there. It will help you create a common talking ground with your inventors.

- Corporate Strategy Group - The Dolcera database will help you refine your technology strategy by allowing you to study competitive strategy of your key competitors. Please bear in mind that 85% of all technical intelligence of your competitors can be studied from patents.

Overview

Biofuels represent effective means of supplying liquid transportation fuels from renewable resources.Of the biofuel options, alcohol fuels offer the most proven and practicable alternative for the conventional transportation fuels.The energy in biomass can be accessed by turning the raw materials, or feedstocks, into a usable form. Transportation fuels are made from biomass through biochemical or thermochemical processes. Known as biofuels, these include ethanol, methanol, biodiesel, biocrude, and methane.

Biomass Sources

- Domestic crops

- Energy crops

- Agricultural Waste

- Industrial Waste

- Municipal Wastes

- Cellulose/Hemicellulose rich material - cotton,wood,plant stalks,paper

- Carbohydrates - sugar,starch,monosaccharides,disaccharides,polysaccharides

- Algae

Biomass Conversion Processes

Thermochemical Processes - The thermochemical conversion of biomass to synthesis gas (syngas) encompasses processes that are carried out in closed systems under reducing (oxygen depleted) or oxidizing (partial oxygen) conditions at high temperatures (typically 1500-2000oF). The primary chemical processes that occur include pyrolysis, oxidation, steam reforming and gasification.

- Pyrolysis - Rapid thermal decomposition of organic compounds in the absence of oxygen to produce gas,char, and liquids.Thermal pyrolysis and steam reforming of biomass are endothermic and typically require a secondary fuel to supply heat to the reaction chamber. This is often supplied with clean syngas recycled back to externally heat the reactor.

- Gasification - high temperature (750 – 850 °C) conversion of solid, carbonaceous fuels into flammable gas mixture (syngas).Require oxygen or air for the conversion.

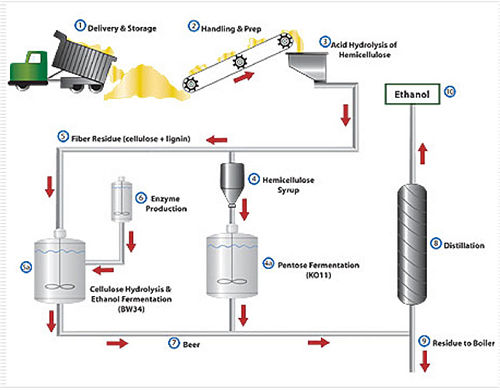

Biochemical Processes - Biochemical conversion processes utilize acid hydrolysis for the conversion of cellulose to sugars,followed by the fermentation of the sugars to bioethanol.

- Fermentation - Alcohol fermentation, like anaerobic digestion, is a biological process in which sugars such as glucose, fructose, and sucrose are converted into cellular energy and thereby produce ethanol and carbon dioxide as metabolic waste products.It requires special attention through a series of living reactions.

- Saccharification - The starch does not itself undergo alcoholic fermentation; it is first converted into maltose and other products by the action of the enzyme diastase (amylase). This diastase is usually supplied by malt - or, in the "amylo" process (described further on) by certain moulds.

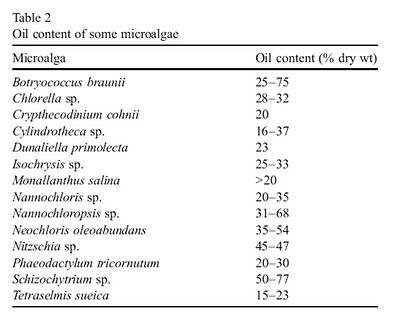

Biofuels from microalgae

Microalgae are sunlight-driven cell factories that convert carbon dioxide to potential biofuels, foods,feeds and high-value bioactives.In addition, these photosynthetic microorganisms are useful in bioremediation applications and as nitrogen fixing biofertilizers.Microalgae can provide several different types of renewable biofuels. These include methane produced by anaerobic digestion of the algal biomass;biodiesel derived from microalgal oil and photobiologically produced biohydrogen.

Unlike other oil crops, microalgae grow extremely rapidly and many are exceedingly rich in oil. Microalgae commonly double their biomass within 24 h. Biomass doubling times during exponential growth are commonly as short as 3.5 h. Oil content in microalgae can exceed 80% by weight of dry biomass.Oil levels of 20–50% are quite common Oil productivity, that is the mass of oil produced per unit volume of the microalgal broth per day, depends on the algal growth rate and the oil content of the biomass. Microalgae with high oil productivities are desired for producing biodiesel.Microalgal biomass production - Producing microalgal biomass is generally more expensive than growing crops. Photosynthetic growth requires light, carbon dioxide, water and inorganic salts. Temperature must remain generally within 20 to 30 °C.Growth medium must provide the inorganic elements that constitute the algal cell. Essential elements include nitrogen (N), phosphorus (P), iron and in some cases silicon.Microalgal biomass contains approximately 50% carbon by dry weight.All of this carbon is typically derived from carbon dioxide. Producing 100 t of algal biomass fixes roughly 183 t of carbon dioxide. Carbon dioxide must be fed continually during daylight hours.Ideally, microalgal biodiesel would be carbon neutral, as all the power needed for producing and processing the algae would come from biodiesel itself and from methane produced by anaerobic digestion of biomass residue left behind after the oils has been extracted.

Large-scale production of microalgal biomass generally uses continuous culture during daylight.In this method of operation, fresh culture medium is fed at a constant rate and the same quantity of microalgal broth is withdrawn continuously.The only practicable methods of large-scale production of microalgae are raceway ponds and tubular photobioreactors.

Microalgal oils differ from most vegetable oils in being quite rich in polyunsaturated fatty acids with four or more double bonds.For example, eicosapentaenoic acid (EPA, C20:5n-3; five double bonds) and docosahexaenoic acid (DHA, C22:6n-3; six double bonds) occur commonly in algal oils.The extent of unsaturation of microalgal oil and its content of fatty acids with more than 4 double bonds can be reduced easily by partial catalytic hydrogenation of the oil.

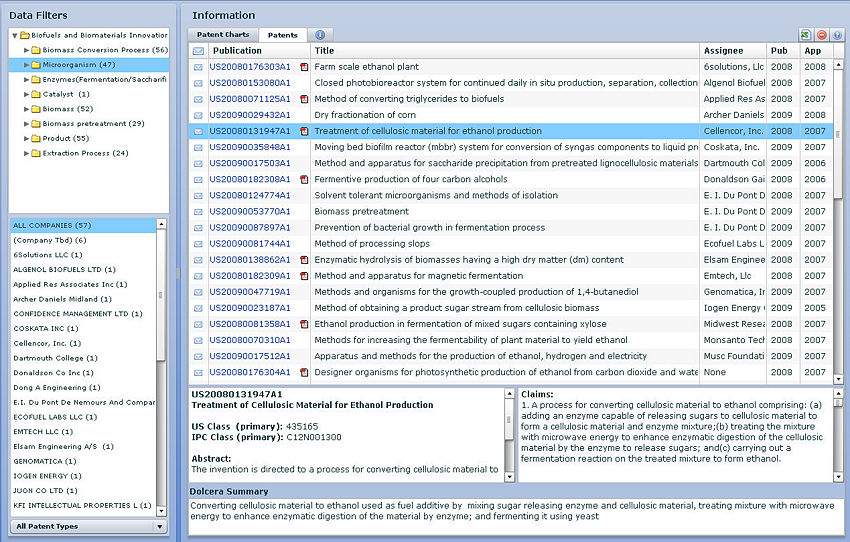

Dashboard

The Dolcera Dashboard for the database can be viewed here:

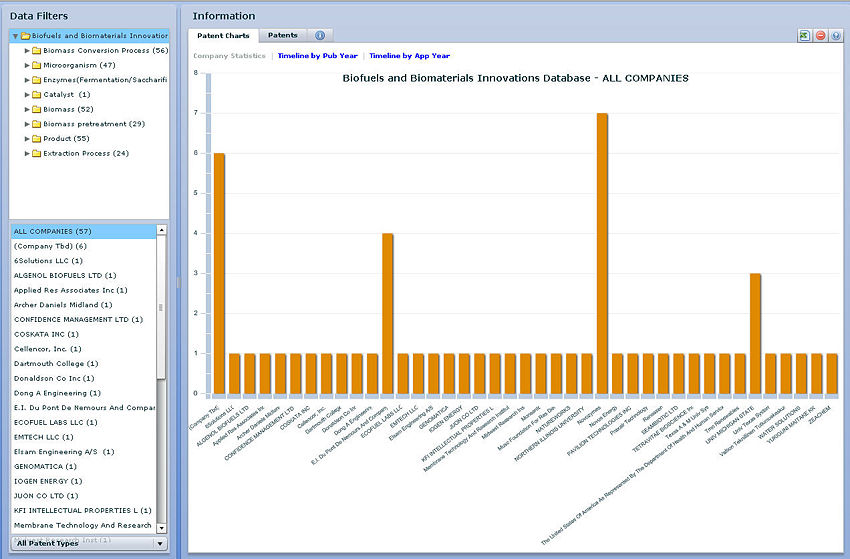

Dashboard for the Biofuels and Biomaterials Innovations Database

NOTE: Install the Flash Player if you are unable to view the Dashboard

Features of the Dashboard can be viewed here

Snapshots of the Dashboard

Search strategy

| S.no | Concept | Scope | Search Query | 1836-date |

| 1 | Vegetable biomass | Full patent specification | ((vegetable ADJ1 biomass) OR vegetable*1 OR hull OR salix OR algae OR plant* OR (sweet ADJ1 corn) OR jatropha OR pulp OR forest*3 OR *grass*2 OR lignocellulos*2 OR cellulos*2 OR bamboo OR hemp OR cannabis OR sisal OR (pongamina ADJ1 pinnata) OR straw OR soapstock OR manure OR timber OR miscanthus OR agricultur*2 OR herbaceous OR food OR shea OR bran OR (switch ADJ1 grass) OR (turf ADJ1 grass) OR buckweat OR (millet ADJ1 husk*1) OR amaranth*2 OR (agro ADJ1 waste) OR leucaena OR gliricidia OR phytoplankton OR potato OR mahua OR pennycress OR cassava OR (vegetable NEAR waste) OR thistle OR olive OR (apple ADJ1 pulp) OR asparagus OR (Panicum ADJ1 virgatum) OR slash OR pea OR willow OR poplar OR copra OR (elephant ADJ1 grass) OR (Cynara ADJ1 Cardunculus) OR cardoon OR (Copaiba ADJ1 Oil) OR (Jojoba ADJ1 Oil) OR (milk ADJ1 bush) OR euphorbia OR tallow OR pine OR babassu OR cupuassu OR fungi OR (vegetable ADJ1 peel*1)OR potato* OR legnin OR slash OR amaranth*2 OR jute OR *wood* OR (Fallopia ADJ1 convolvulus) OR (Butyrospermum ADJ1 parkii) OR leaves OR leaf OR paper*1 OR fruit*1 OR stem* OR aggricultur* OR (municipal ADJ1 waste) OR (vegetable ADJ1 oil) OR grape*1 OR hyacinth OR biomass* OR kenaf* OR honge OR starch OR carbohydrate* OR stover* OR sunflower OR Pongamia OR waste* OR husk* OR molasse* OR garbage OR scrap* OR triticale* OR excreta OR silage* OR orchard* OR castor* OR hay* OR crop* OR fodder* OR seed* OR oilseed* OR soy* OR (animal ADJ1 fat) OR flax OR cotton* OR mushroom* OR catfish* OR camelina OR cheese OR pine* OR birch OR sawdust OR chicory OR artichoke* OR *saccharide* OR microalgae OR algal) | 7818012 hits |

| 2 | Food Grains | Full patent specification | (rice OR wheat OR barley OR cotton OR maize OR corn* OR grain*1 OR linseed OR (cotton ADJ1 seed) OR peanut* OR rapeseed* OR (petroleum ADJ1 nut ADJ1 oil) OR (flax ADJ1 seed) OR sorghum OR oil* OR soyabean OR legume OR sorghum OR (canola ADJ1 oil) OR (palm ADJ1 oil) OR sunflower OR (antichoke ADJ1 oil) OR (perilla ADJ1 oil) OR (Moringa ADJ1 Oleifera) OR (ben ADJ1 oil) OR (honge ADJ1 Oil) OR sesame OR mustard OR linseed OR oat*1 OR rye*1 OR cereal*1 OR millet*1 OR groundnut*1 OR peanut*1 OR coffee OR seed* OR rapseed OR (oil ADJ1 seed) OR (coconut ADJ1 oil)) | 5474390 hits |

| 3 | Sugar crops | Full patent specification | (Bagasse OR (Beta ADJ1 vulgaris) OR molasses OR sugarcane OR (sugar ADJ1 beat) OR beetroot OR chard OR (fodder ADJ1 beet) OR Saccharum OR beet*) | 120301 hits |

| 4 | Combined Query | 1 OR 2 OR 3 | 10132435 hits | |

| 5 | Alcohols | Claims,title,abstract | bioalcohol* OR ethanol OR (ethyl ADJ1 alcohol) OR (methyl ADJ1 carbinol) OR methylcarbinol OR (anhydrous ADJ1 alcohol) OR (ethyl ADJ1 hydrate) OR (ethyl ADJ1 hydroxide) OR anhydrol OR bioethanol OR *methanol OR (methyl ADJ1 alcohol) OR (methyl ADJ1 hydrate) OR (methyl ADJ1 hydroxide) OR methylol OR carbinol OR (wood ADJ1 naptha) OR biomethanol OR propanol OR (propyl ADJ1 alcohol) OR biopropanol OR (propan ADJ3 o*1) OR butanol OR (butyl ADJ1 alcohol) OR biobutanol OR (butan ADJ3 o*1) OR (propyl ADJ1 carbinol) OR propylcarbinol OR Butylalcohol OR methylolpropane OR (methylol ADJ1 propane) OR (Alcohol ADJ1 butylique) OR hydroxybutane OR (hydroxy ADJ1 butane) OR pentanol OR (pentyl ADJ1 alcohol) OR biopentanol OR (amyl ADj1 alcohol) OR amylalcohol OR (Butyl ADJ1 carbinol) OR butylcarbinol OR hexanol OR amylcarbinol OR (amyl ADJ1 carbinol) OR (capryl ADJ1 alcohol) OR caprylalcohol OR (pentyl ADJ1 carbinol) OR (hexyl ADj1 alcohol) OR hydroxyhexane OR (hydroxy ADJ1 hexane) OR biohexanol OR (Caproic ADJ1 alcohol) OR (hexan ADJ3 o*1) OR heptanol OR (heptyl ADJ1 alcohol) OR bioheptanol OR (heptan ADJ3 o*1) OR Gentanol OR (Enanthic ADJ1 alcohol) OR hydroxyheptane OR (hydroxy ADJ1 heptane) OR (Hexyl ADJ1 carbinol) OR ((C3 OR C4 OR c5 OR c6 OR C7 OR C8 OR C9) ADJ1 alcohol) OR octanol OR biooctanol OR (octyl ADJ1 alcohol) OR (octan ADJ3 o*1) OR ethylhexanol OR (ethyl ADJ1 hexanol) OR hydroxyoctane OR (hydroxy ADJ1 octane) OR amylethylcarbinol OR (amyl ADJ1 ethyl ADJ1 carbinol) OR (Caprylic ADJ1 alcohol) OR (Capryl ADJ1 alcohol) OR (ethyl ADJ1 amyl ADJ1 carbinol) OR ethylamylcarbinol OR (heptyl ADJ1 carbinol) OR nonanol OR (nonyl ADJ1 alcohol) OR (nonan ADJ3 o*1) OR octylcarbinol OR (octyl ADJ1 carbinol) OR hydroxynonane OR (hydroxy ADJ1 nonane) OR alcohol* OR glycol* OR (pantan ADJ1 o*1) OR biofuel*) | 835737 hits |

| 6 | Current IPC | C12P000702 OR C12P000706 OR C12P000704 OR C12P000708 OR C12P000710 OR C12P000712 OR C12P000714 OR C12P000716 OR C12P000720 OR C12P000728 OR C12P000736 OR C12P000754 OR C12P000752 OR C12P000740 OR C07C003104 OR C07C003108 OR C12F000304 OR C12F000308 OR C12C001107 OR C12C001109 OR C12C001100 OR C12C001110 OR C12C000500 OR C07C002976 | 23724 hits | |

| 7 | Combined Query | 4 AND 5 AND 6 | 6462 hits | |

| 8 | Biodiesel production | Full patent specification | (biodiesel OR (bio ADJ1 diesel) OR (methyl ADJ1 ester*) OR (methyl ADJ1 soyate) OR (methyl ADJ1 tallowate) OR biofuel*)SAME (production OR prepar* OR synthes* OR produce OR produced OR bioproduction OR biosynthesis OR biometabolic OR bioconversion OR biotransformation OR yeast OR bacteria OR microb* OR micro*1organism) | 69672 hits |

| 9 | Algea | Claims,title,abstract | (algae OR microalgea OR algal OR Bacillariophyceae OR Chlorophyceae OR Cyanophyceae OR Xanthophyceaei OR Chrysophyceae OR Chlorella OR Crypthecodinium OR Schizocytrium OR Nannochloropsis OR Ulkenia OR Dunaliella OR Cyclotella OR Navicula OR Nitzschia OR Cyclotella OR Phaeodactylum OR Thaustochytrids OR Botryococcus braunii OR (Chlorella ADJ1 protothecoides)) | 12914 hits |

| 10 | Combined Query | 8 AND 9 | 588 hits | |

| 11 | Combined Query | 10 OR 7 | 7015 hits(3932 unique hits) | |

INPADOC Search Query

| S.no | Concept | Scope | Search Query | Years | Hits |

| 1 | Title,abstract | INPADOC | (bioalcohol* OR ethanol OR (ethyl ADJ1 alcohol) OR (methyl ADJ1 carbinol) OR methylcarbinol OR (anhydrous ADJ1 alcohol) OR (ethyl ADJ1 hydrate) OR (ethyl ADJ1 hydroxide) OR anhydrol OR bioethanol OR *methanol OR (methyl ADJ1 alcohol) OR (methyl ADJ1 hydrate) OR (methyl ADJ1 hydroxide) OR methylol OR carbinol OR (wood ADJ1 naptha) OR biomethanol OR propanol OR (propyl ADJ1 alcohol) OR biopropanol OR butanol OR (butyl ADJ1 alcohol) OR biobutanol OR (propyl ADJ1 carbinol) OR propylcarbinol OR Butylalcohol OR methylolpropane OR (methylol ADJ1 propane) OR (Alcohol ADJ1 butylique) OR hydroxybutane OR (hydroxy ADJ1 butane) OR pentanol OR (pentyl ADJ1 alcohol) OR biopentanol OR (amyl ADj1 alcohol) OR amylalcohol OR (Butyl ADJ1 carbinol) OR butylcarbinol OR hexanol OR amylcarbinol OR (amyl ADJ1 carbinol) OR (capryl ADJ1 alcohol) OR caprylalcohol OR (pentyl ADJ1 carbinol) OR (hexyl ADj1 alcohol) OR hydroxyhexane OR (hydroxy ADJ1 hexane) OR biohexanol OR (Caproic ADJ1 alcohol) OR heptanol OR (heptyl ADJ1 alcohol) OR bioheptanol OR Gentanol OR (Enanthic ADJ1 alcohol) OR hydroxyheptane OR (hydroxy ADJ1 heptane) OR (Hexyl ADJ1 carbinol) OR octanol OR biooctanol OR (octyl ADJ1 alcohol) OR ethylhexanol OR (ethyl ADJ1 hexanol) OR hydroxyoctane OR (hydroxy ADJ1 octane) OR amylethylcarbinol OR (amyl ADJ1 ethyl ADJ1 carbinol) OR (Caprylic ADJ1 alcohol) OR (Capryl ADJ1 alcohol) OR (ethyl ADJ1 amyl ADJ1 carbinol) OR ethylamylcarbinol OR (heptyl ADJ1 carbinol) OR nonanol OR (nonyl ADJ1 alcohol) OR octylcarbinol OR (octyl ADJ1 carbinol) OR hydroxynonane OR (hydroxy ADJ1 nonane) OR glycol* OR biofuel*) | 1836-date | 497701 hits |

| 2 | IPC | INPADOC | C12P OR B01D OR C12C OR C12D | 1836-date | 538899 hits |

| 3 | Limit by country code | INPADOC | US OR WO OR DE OR EP OR FR OR JP OR GB | 1836-date | 350751 hits |

| 4 | Combined Query | 2 NOT 3 | 188138 hits | ||

| 5 | Final Query | 1 AND 4 | 5392 (2931 unique records) | ||

F-term search

| F-Term Search in JPO | ||

| Topic | Term | Description |

| Theme for F Term | 4B064 | Production of compounds from microorganisms |

| F-Terms | AC01 | Alcohol |

| AC03 | Ethanol | |

| AC04 | Butanol | |

- Number of records: 804

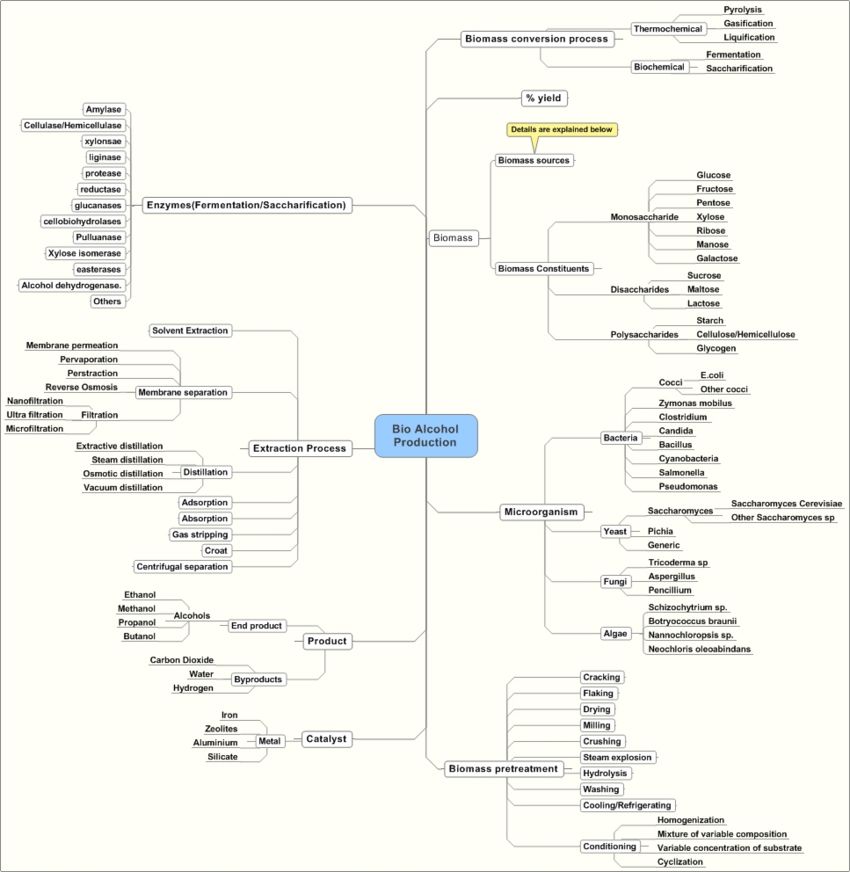

Bioalcohol Production Taxonomy

- Taxonomy used for the categorization of patents in the Dolcera Dashboard

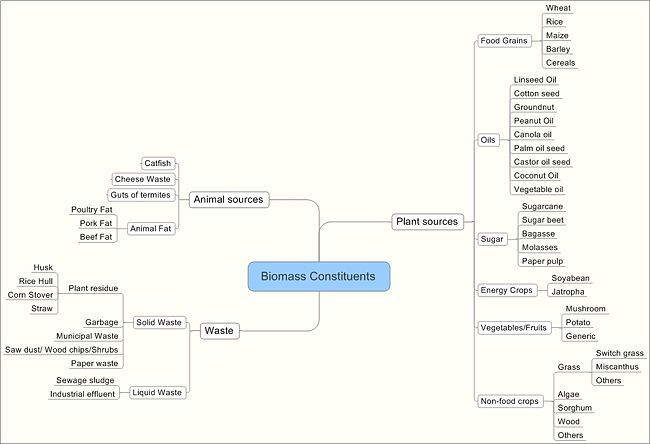

Biomass Sources Taxonomy sample

Interactive taxonomy mind map

Use the mouse(click and drag/scroll up or down/click on nodes) to explore nodes in the detailed taxonomy

Click on the red arrow on the side of a node name to view the content for that particular node in the dashboard

Patent Analysis

Sample Analysis

| S.No. | Publication No. | Publication Year | Assignee / Applicant | Title | Abstract | Dolcera summary |

| 1 | US20090053777 | 2009 | Alliance For Sustainable Energy, Llc | Process For Concentrated Biomass Saccharification | Processes for saccharification of pretreated biomass to obtain high concentrations of fermentable sugars are provided. Specifically, a process was developed that uses a fed batch approach with particle size reduction to provide a high dry weight of biomass content enzymatic saccharification reaction, which produces a high sugars concentration hydrolysate, using a low cost reactor system. | Process for producing high-sugar content hydrolysate from biomass where as on further fermentation of the hydrolysate alcohols namely methanol, ethanol, propanol, isopropanol, butanoletc are produced. |

| 2 | US20090047718 | 2009 | Tetravitae Bioscience, Inc. | Methods and compositions for producing solvents | Described herein are methods, compositions and synthetic biology approaches for solvent production, including but not limited to butanol production. Described herein are recombinant bacteria and yeast strains which may be used in production of a solvent, including but not limited to butanol, from lignocellulosic and other plant-based feedstocks. Described herein are methods of producing solvents, including but not limited to butanol, using bacteria and yeast strains. Described herein are methods of producing organisms that display highly efficient butanol production. | New first recombinant solventogenic organism having altered gene expression involved in solvent production pathway relative to expression in first organism strain prior to its transformation, useful for producing a solvent, e.g. butanol |

| 3 | US20090053771 | 2009 | Board Of Trustees Of Michigan State University | Process for making fuels and chemicals from AFEX-treated whole grain or whole plants | A process for hydrolyzing whole grain or whole plant biomass after an Ammonia Fiber Explosion (AFEX) process step is described. The process preferably uses a biomass that is hydrolyzed using a different combination of enzymes (amylase, cellulase and hemicellulase) to sugars for fermentation to produce ethanol. Harvesting the whole plant inclusive of grains and stalk for ethanol bio-processing is an economical route for future biorefineries. In addition to sugars, various value-added products like proteins and oil can be co-generated. | Producing sugars from plant biomass involves treating comminuted plant biomass comprising cellulose, hemicellulose, and starch with concentrated ammonia under pressure; and hydrolyzing biomass using enzyme containing amylase and cellulase |

| 5 | US20090023187 | 2009 | Iogen Energy Corporation | Method of obtaining a product sugar stream from cellulosic biomass | A process for obtaining a product sugar stream from cellulosic biomass is disclosed. In one process, the cellulosic biomass is pretreated at a pH between about 0.4 to 2.0 by adding one or more than one acid to produce a pretreated cellulosic biomass comprising acetic acid. One or more than one base is then added to the pretreated cellulosic biomass to adjust the pretreated cellulosic biomass to a pH of about 4.0 to about 6.0 to produce a neutralized cellulosic biomass comprising inorganic salt and acetate salt. The neutralized biomass is then hydrolyzed by cellulase enzymes to produce a crude sugar stream. Insoluble residue is separated from the crude sugar stream and the resulting clarified sugar stream is treated using ion exclusion chromatography at about pH 5.0 to about 10.0 to produce one or more raffinate streams and a product stream. The raffinate stream comprises inorganic salts and acetate salts, and the product stream comprises sugar. The product stream may then be fermented or otherwise further processed. In an alternate process, a product sugar stream is obtained from a crude sugar stream that is produced from conversion of cellulosic biomass to sugar. The cellulosic biomass may be produced using any suitable method. In this process the crude sugar stream is treated using ion exclusion chromatography at about pH 5.0 to about 10.0 to produce one or more than one raffinate stream comprising sulfate and acetate salts, and a product stream comprising sugar, and the product sugar stream is obtained. | The present invention relates to a method of obtaining a product sugar stream from cellulosic biomass and microbial conversion to ethanol. |

| 5 | US20090082600 | 2009 | Northern Illinois University | Native homoethanol Pathway for ethanol production in E. coli | A native homoethanol pathway including chromosomal deletions of genes that are competitive with the native homoethanol pathway, and a highly anaerobically expressed pyruvate dehydrogenase operon. Bacteria including the native homoethanol pathway. A method of making a bacteria derivative including a native homoethanol pathway by deleting genes that are competitive with ethanol production pathways, and performing transcriptional gene fusion and highly anaerobically expressing pyruvate dehydrogenase operon. A method of producing ethanol by fermenting bacteria including the native homoethanol pathway with biomass, and producing ethanol. Ethanol produced by the above method. | Method of producing ethanol in E.coli the steps of fermenting bacteria including the native homoethanol pathway with biomass with a yield of 90% under anaerobic conditions. |

| 6 | US20090087897 | 2009 | E. I. Du Pont De Nemours And Company | Prevention of bacterial growth in fermentation process | A fermentation process for the production of ethanol from natural sources, such as corn, comprising introducing a fermentable sugar, an inoculant, and a stabilized chlorine dioxide into a fermentation system is disclosed. The stabilized chlorine dioxide is added preventatively to the fermentation system, at concentrations in the fermentation system of acetic acid no greater than 0.30% (weight/volume) and lactic acid no greater than 0.60% (weight/volume). The stabilized chlorine dioxide is added in an amount effective to substantially prevent growth of bacteria. | A fermentation process to produce ethanol from natural sources, such as corn, comprising introducing a fermentable sugar, an inoculant, and a stabilized chlorine dioxide into a fermentation system forpreventing bacterial infection. |

- Click here for F-term on target sheet - Dated August 24, 2009

- Click here for Sample Patent Analysis Sheet - Dated July 30, 2009

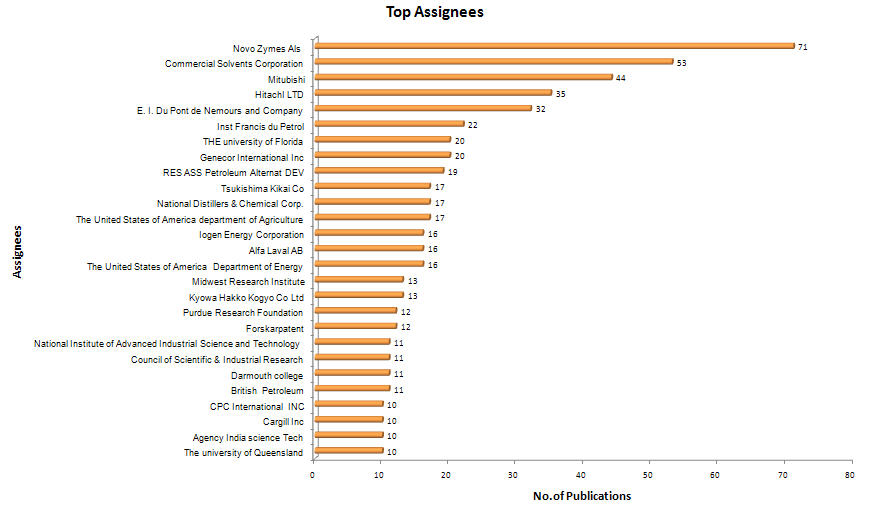

Patenting activity by Assignee/Applicant

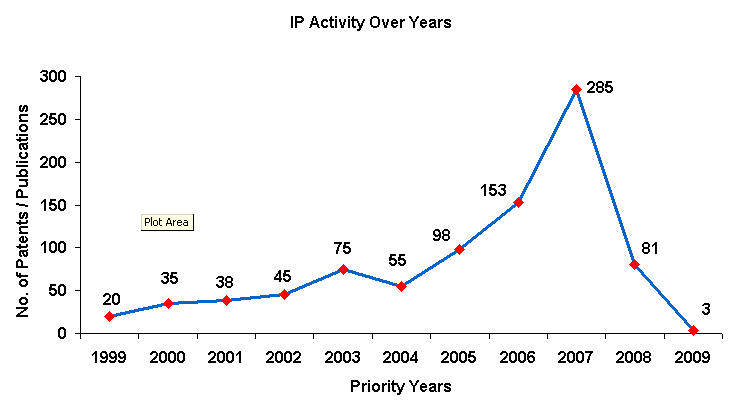

Patenting activity by Priority Years

- NOTE: Patenting Activity graph is based on the earliest Priority years, therefore there is decline in the graph.

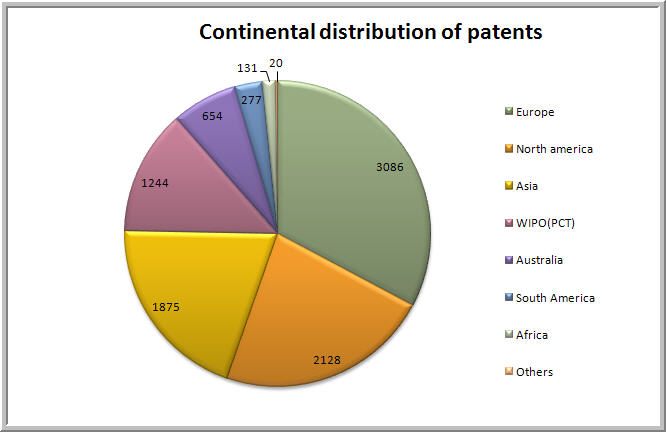

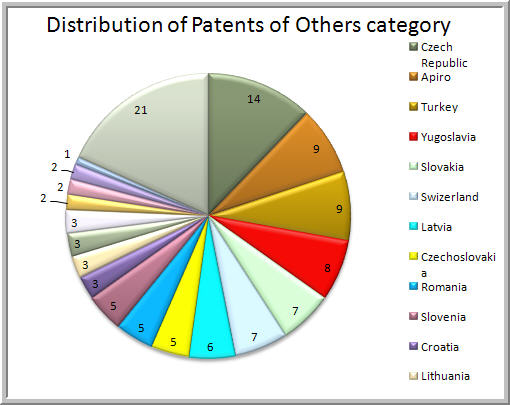

Continental distribution of patents

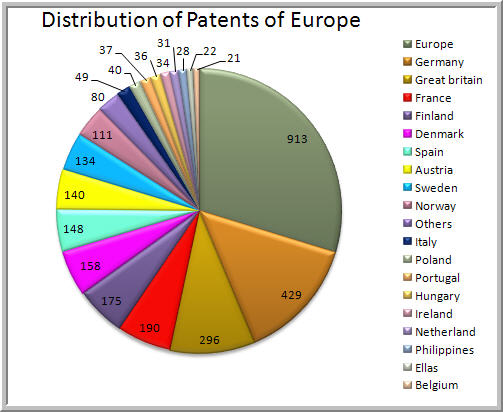

Patent distribution in Europe

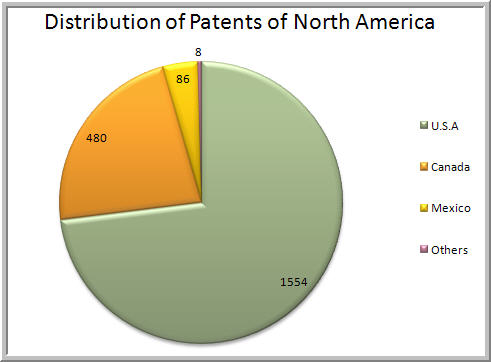

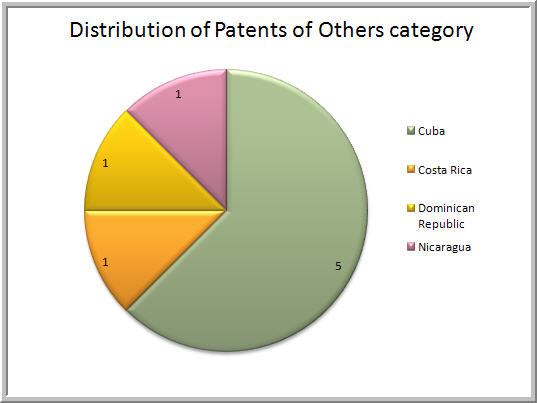

Patent distribution in North America

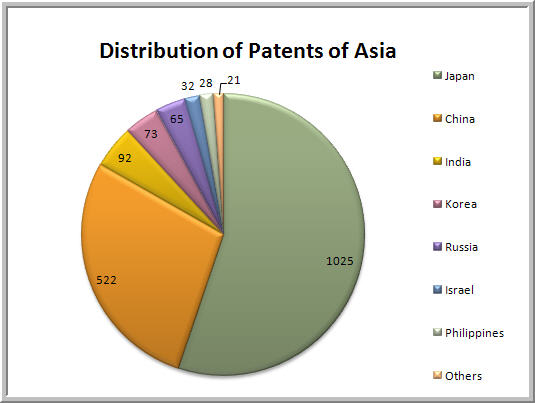

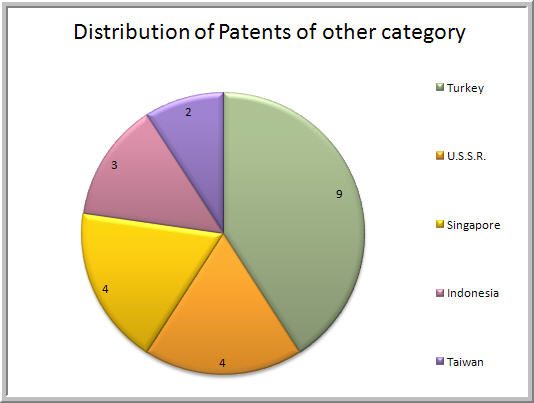

Patent distribution in Asia

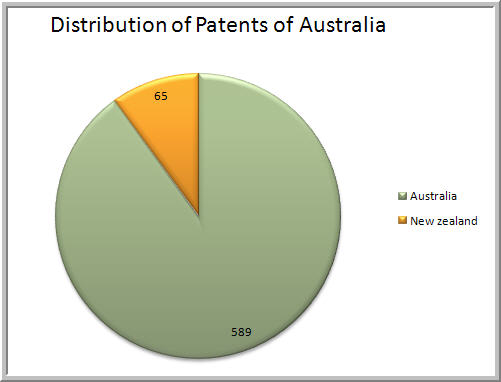

Patent distribution in Australia

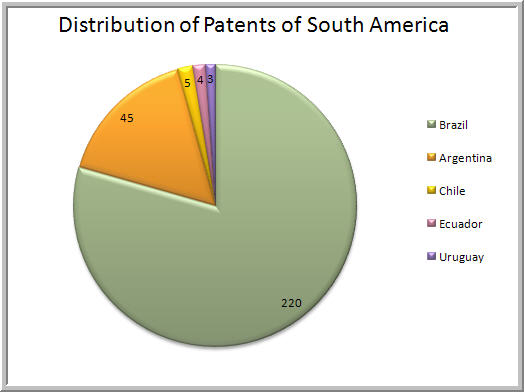

Patent distribution in South America

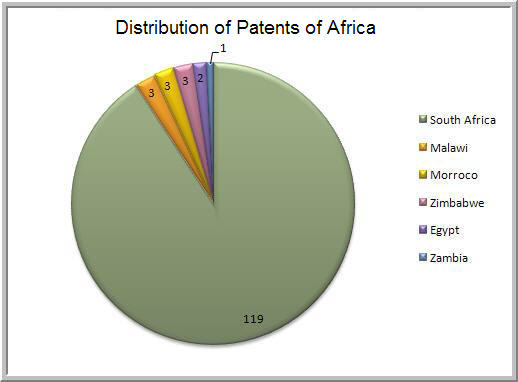

Patent distribution in Africa

Scientific Publications

Search Strategy

| S.no | Search Query | Date | Hits | Relevancy |

| 1 | ((fermentation OR bioconversion OR biotransformation OR biosynthesis OR biometabolism OR biocatalytic OR biosynthesize) AND (biofuel OR biofuels OR ethanol OR butanol OR propanol OR pentanol OR biogas OR biodiesel OR isobutanol OR bioethanol OR isopropanol OR isopentanol OR octanol OR nonanol OR biooctanol OR biononanol OR hexanol OR heptanol OR biohexanol OR bioheptanol )) AND ((production OR produce OR manufacture)) | 1900/01/01 to 2009/08/03 | 10,113 hits | 45-50% |

Sample Analysis

| S.NO | Title | Abstract | Authors | Company | Citation | Journal name | Publication Date |

| 1 | Metabolic engineering of microorganisms for biofuels production: from bugs to synthetic biology to fuels | The ability to generate microorganisms that can produce biofuels similar to petroleum-based transportation fuels would allow the use of existing engines and infrastructure and would save an enormous amount of capital required for replacing the current infrastructure to accommodate biofuels that have properties significantly different from petroleum-based fuels. Several groups have demonstrated the feasibility of manipulating microbes to produce molecules similar to petroleum-derived products, albeit at relatively low productivity (e.g. maximum butanol production is around 20 g/L). For cost-effective production of biofuels, the fuel-producing hosts and pathways must be engineered and optimized. Advances in metabolic engineering and synthetic biology will provide new tools for metabolic engineers to better understand how to rewire the cell in order to create the desired phenotypes for the production of economically viable biofuels. | Lee, S.K. / Chou, H. / Ham, T.S. / Lee, T.S. / Keasling, J.D. | Joint BioEnergy Institute, Emeryville, CA USA | Lee, S.K. / Chou, H. / Ham, T.S. / Lee, T.S. / Keasling, J.D. , Current Opinion in Biotechnology, 19 (6), p.556-563, Dec 2008 | Current Opinion in Biotechnology | Dec-08 |

| 2 | Metabolic engineering for advanced biofuels production from Escherichia coli | Global energy and environmental problems have stimulated increasing efforts toward synthesizing liquid biofuels as transportation energy. Compared to the traditional biofuel, ethanol, advanced biofuels should offer advantages such as higher energy density, lower hygroscopicity, lower vapor pressure, and compatibility with existing transportation infrastructure. However, these fuels are not synthesized economically using native organisms. Metabolic engineering offers an alternative approach in which synthetic pathways are engineered into user-friendly hosts for the production of these fuel molecules. These hosts could be readily manipulated to improve the production efficiency. This review summarizes recent progress in the engineering of Escherichia coli to produce advanced biofuels. | Atsumi, S. / Liao, J.C | Department of Chemical and Biomolecular Engineering, University of California, Los Angeles CA USA | Atsumi, S. / Liao, J.C. , Current Opinion in Biotechnology, 19 (5), p.414-419, Oct 2008 | Current Opinion in Biotechnology | Oct-08 |

| 3 | New microbial fuels: a biotech perspective | Bioethanol and plant oil-derived biodiesel are generally considered first generation biofuels. Recognizing their apparent disadvantages, scientists and engineers are developing more sustainable and economically feasible second generation biofuels. The new microbial fuels summarized here have great potential to become viable replacements or at least supplements of petroleum-derived liquid transportation fuels. Yields and efficiencies of the four metabolic pathways leading to these microbial fuels — mostly designed and optimized in Escherichia coli and Saccharomyces cerevisiae using modern tools of metabolic engineering and synthetic biology — and the robustness of the biocatalysts that convert the metabolic intermediates to, in some cases, finished and engine-ready fuels, will determine if they can be commercially successful and contribute to alleviating our dependence on fossil fuels. | Rude, M.A. / Schirmer, A | LS9, Inc,CA USA. | Rude, M.A. / Schirmer, A. , Current Opinion in Microbiology, 12 (3), p.274-281, Jun 2009 | Current Opinion in Microbiology | Jun-09 |

| 4 | Biofuel alternatives to ethanol: pumping the microbial well | Engineered microorganisms are currently used for the production of food products, pharmaceuticals, ethanol fuel and more. Even so, the enormous potential of this technology has yet to be fully exploited. The need for sustainable sources of transportation fuels has generated a tremendous interest in technologies that enable biofuel production. Decades of work have produced a considerable knowledge-base for the physiology and pathway engineering of microbes, making microbial engineering an ideal strategy for producing biofuel. Although ethanol currently dominates the biofuel market, some of its inherent physical properties make it a less than ideal product. To highlight additional options, we review advances in microbial engineering for the production of other potential fuel molecules, using a variety of biosynthetic pathways. | Fortman, J.L. / Chhabra, S. / Mukhopadhyay, A. / Chou, H. / Lee, T.S. / Steen, E. / Keasling, J.D | Joint BioEnergy Institute, CA USA. | Fortman, J.L. / Chhabra, S. / Mukhopadhyay, A. / Chou, H. / Lee, T.S. / Steen, E. / Keasling, J.D. , Trends in Biotechnology, 26 (7), p.375-381, Jul 2008 | Trends in Biotechnology | Jul-08 |

| 5 | Progress and recent trends in biodiesel fuels | Fossil fuel resources are decreasing daily. Biodiesel fuels are attracting increasing attention worldwide as blending components or direct replacements for diesel fuel in vehicle engines. Biodiesel fuel typically comprises lower alkyl fatty acid (chain length C14–C22), esters of short-chain alcohols, primarily, methanol or ethanol. Various methods have been reported for the production of biodiesel from vegetable oil, such as direct use and blending, microemulsification, pyrolysis, and transesterification. Among these, transesterification is an attractive and widely accepted technique. The purpose of the transesterification process is to lower the viscosity of the oil. The most important variables affecting methyl ester yield during the transesterification reaction are the molar ratio of alcohol to vegetable oil and the reaction temperature. Methanol is the commonly used alcohol in this process, due in part to its low cost. Methyl esters of vegetable oils have several outstanding advantages over other new-renewable and clean engine fuel alternatives. Biodiesel fuel is a renewable substitute fuel for petroleum diesel or petrodiesel fuel made from vegetable or animal fats; it can be used in any mixture with petrodiesel fuel, as it has very similar characteristics, but it has lower exhaust emissions. Biodiesel fuel has better properties than petrodiesel fuel; it is renewable, biodegradable, non-toxic, and essentially free of sulfur and aromatics. Biodiesel seems to be a realistic fuel for future; it has become more attractive recently because of its environmental benefits. Biodiesel is an environmentally friendly fuel that can be used in any diesel engine without modification | Demirbas, A. | Sila Science, Trabzon, Turkey | Demirbas, A. , Energy Conversion and Management, 50 (1), p.14-34, Jan 2009 | Energy Conversion and Management | Jan-09 |

| Contact Dolcera |

|---|

| Email: info@dolcera.com |

| Phone: +1-650-269-7952, +91-40-2355-3493 |