Supply Chain RFID Applications

Contents

Introduction to RFID technology in supply chain

The supply chain is a complex multi-stage process which involves everything from the procurement of raw materials used to develop products, and their delivery to customers via warehouses and distribution centers. Supply chains exist in service, manufacturing and retail organizations.

Although, the complexity of the chain may vary greatly from industry to industry and firm to firm. Supply chain management can be seen as the supervision of information and finances of these materials, as they move through the different processes, by coordinating and integrating the flows within and among the different companies involved.

The efficiency of the supply chain has a direct impact on the profitability of a company. It is no surprise therefore to find that many large corporate companies have made it a key part of their strategy, and invested heavily in software systems (ERP, WMS...) and IT infrastructure designed to control inventory, track products and manage associated finance.

RFID will bring a new dimension to supply chain management by providing a more efficient way of being able to identify and track items at the various stages throughout the supply chain. It will allow product data to be captured automatically, and therefore be more quickly available for use by other processes such as ASN, stock management and real time billing.

RFID - Market Potential

- The global forecast RFID hardware, middleware, and IT market was worth $640 million in 2005. In 2006, this number will grow to more than $713 million, and is projected to reach more than $1.0 billion by 2011 at an average annual growth rate (AAGR) of 8.0%

- The RFID market is anticipated to continue to grow rapidly in these and many other market sectors and industries including the food and drug industry, propelled by United States FDA mandates. The technical issues that have made standardization more challenging are heading toward resolution with the emergence of the second-generation of UHF RFID

- Retail RFID is estimated currently at just under 27% of the overall RFID market, and supply chain management (SCM) applications, when considered as separate from warehouse and distribution and transportation, represents just over 15% of the overall RFID market. These distributions will undoubtedly change rapidly, and should be reconsidered at regular time intervals as the RFID technology and established and emerging markets mature (Source - BCC Research)

Patent analytics

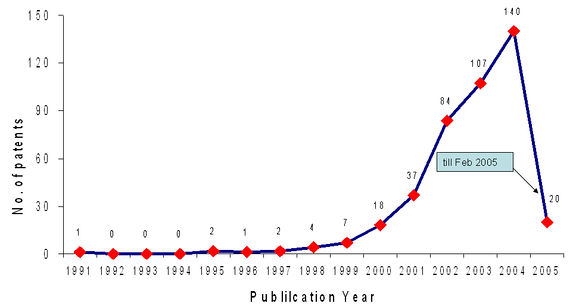

IP landscape over years

- According to the search data IP activity in RFID base supply chain applications seems to have started during the year 1991

- The graph shows terrific growth from 2000 onwards and high activity during 2004 with 140 patents records alone

- Around 423 patents have been published in the span of 4.2 years from 2000 till date (Feb. 2005) indicating the potential in the field

IP landscape by region

IP landscape of RFID base supply chain - Based on selected 30 records

The present graph and interpretation is based on selected 30 records. The graph reveals that the growth in RFID based supply chain applications patenting has been across all the regions. United States is more active than Europe, Japan and Australia

Competitor landscape

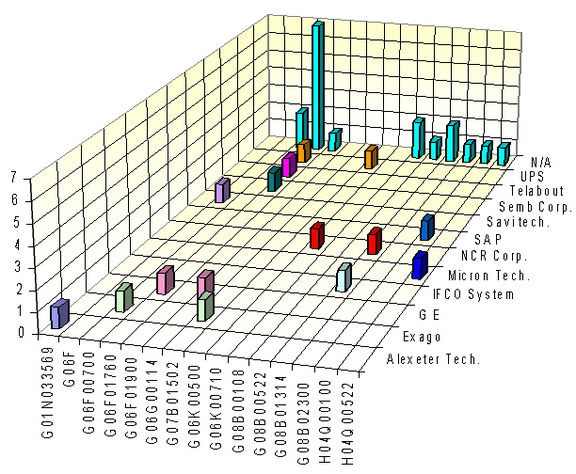

Growth in RFID base supply chain - The present graph and interpretation is based on selected 30 records.

- The graph indicate SAP as leading and consistent player with 3 patent records

- EXAGO seems to be the new entrant in 2005

- It is interesting to note that the competitors in 2004 have not shown any activity in the beginning of 2005

Technology trend

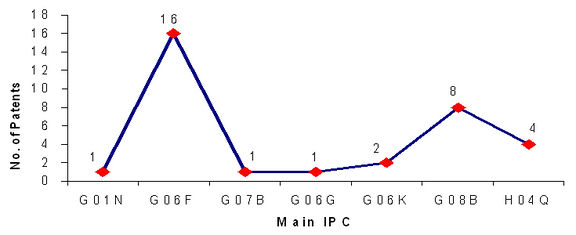

Technology Trend (Main IPC) - Based on selected 30 records

| IPC Code | Description |

| G01N | Measuring, Testing – Investigating or analyzing materials by determining their chemical or physical properties. |

| G06F | Computing, calculating, counting - Electric Digital Data Processing |

| G07B | Checking device - Ticket-issuing; Fare-Registering Apparatus; Franking apparatus |

| G06G | Computing, calculating, counting – Analogue computers |

| G06K | Recognition of data; Presentation of data; Record carriers; Handling record carriers |

| G08B | Signaling - Signaling Or Calling Systems; Order Telegraphs; Alarm Systems |

| H04Q | Electric Communication Technique – Selecting (Switches, relays etc.) |

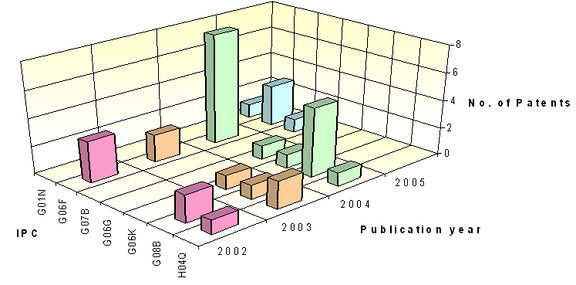

Technology landscape (Main IPC) - Growth in RFID base supply chain

The present graph and interpretation is based on selected 30 records.

- It is evident from graph that G06F (Electric Digital Data Processing) technology is widely used in RFID based supply chain applications showing continues progress through out

- The progress indicates key technology area targeted by many players and having market potential

- Followed by G08B (Signaling), H04Q (Electric Communication Technique ) and G06K (Recognition of data; Presentation of data; Record carriers; Handling record carriers)

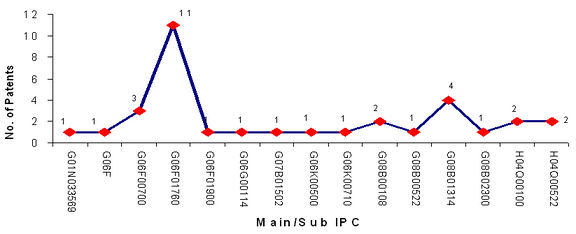

Technology Trend (Sub-class)

(Based on select 30 records)

| IPC Code | Description |

| G01N033569 | Measuring, testing or investigating or analyzing material by determining their chemical or physical properties for microorganisms |

| G06F00700 | Methods or arrangements for processing data by operating upon the order or content of the data handled |

| G06F01760 | Administrative, commercial, managerial, supervisory or forecasting purposes -electronic cash registers other than digital data processing aspects |

| G06F01900 | Record carriers for use with machines and with at least a part designed to carry digital markings |

| G06G00114 | Hand manipulating computing device for arrangements G07B01502 |

| G06K00500 | apparatus for collecting fares, tolls or entrance fee at control point with provision of taking account of variable factors such as distance or time e.g. for passenger transport |

| G06K00710 | Recognition of Data; Presentation of Data; Record Carriers; Handling Record Carriers by electromagnetic radiation, e.g. optical sensing by corpuscular radiation |

| G08B00108 | Signaling Or Calling Systems; Order Telegraphs; Alarm Systems for signaling characterized solely by the form of transmission of signal using electronic transmission |

| G08B00522 | Visible calling system, e.g. personal calling systems remote indication of seat occupied using electric or electromagnetic transmission |

| G08B01314 | Burglar, theft, or intruder alarm by lifting or attempted removal of hand – portable articles. |

| G08B02300 | Alarm responsive to unspecified or abnormal conditions |

| H04Q00100 | Electrical communication technique, details of selecting apparatus or arrangement |

| H04Q00522 | Selecting arrangements where one or more subscriber stations are connected by the same line into the exchanges. The subordinate center not permitting interconnection of subscriber connected thereto |

Technology landscape – Assignee wise

(Based on select 30 records)

According to the present data, most of the leading players have focused on building sound: Administration, commerce, management, supervision and forecasting (electronic cash registers other than digital data processing) aspects for RFID-base supply chain applications

Qualitative Analysis

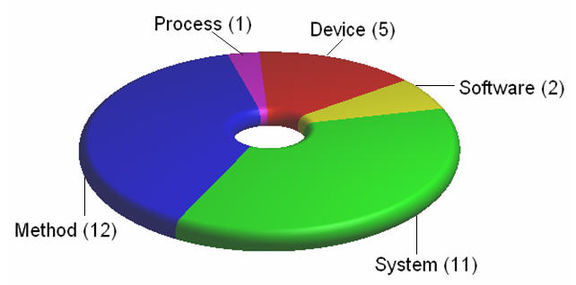

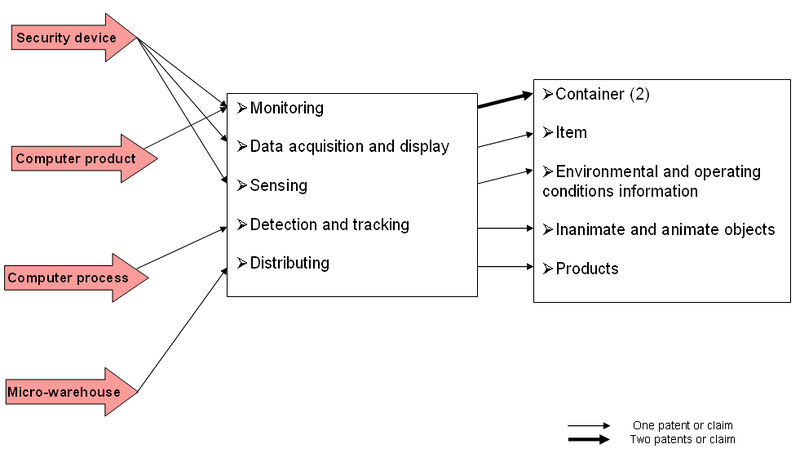

Classification of patents based on main claims

The following graph indicates various subjects that have been covered by various assignee in the area of RFID based supply chain applications. The various subjects are the result of SAO analysis. More granularity on subjects is presented in next slide in the form of clusters.

SAO analysis clustering

Problem Vs Solutions

| Prior art Problems | Solutions | Patent number |

| 1. A central system has limited visibility of containers in the global supply chain. 2. Drawback of the central system is the delay in alerts concerning the container. 3. Typical central systems have difficulty in collecting reliable information across heterogeneous systems. |

A decentralized state system comprising containers to automatically provide continuous and uniform monitoring of a container state is needed. A container should be robustly configured with localized logic capable of determining a state in response to real-time events experienced by the container relative to dynamic and static event information concerning expected events. State determinations made through local information are more reliable to typical prior art systems that use central systems to make inferences about the security state. |

US20040246130 |

| 1. A major disadvantage of all transponder based tag designs is that special anti-collision methods. 2. A short range reader must be used to individually address each tag within the larger field. 3. A second major disadvantage is that to obtain long ranges (100-1,000 feet), higher frequencies are required, and these lead to high power consumption. |

1. & 2. By using lower frequencies (not exceeding 1 MHz, and typically under 300 KHz) and a base station design that uses large loop antennas (such as 10.times.10 feet to 500.times.500 feet) and by transmitting a digital ID to selectively activate a selected client tag, rather than a non-selective signal which would activate many tags simultaneously 3. Networked RF Tags (NRF Tags) have significantly reduced power consumption and long range (1000 sq feet to 10,000 sq feet per antenna), have the power capacity to add displays (e.g. LCD) and light emitting diodes (LED’s) and detectors, and buttons so they may become fully interactive "tag clients" (this is not possible with transponder). |

US20040201454 |

| 1. One drawback to these systems is that they require the goods to be passed through designated gateway areas, typically causing great inconvenience. 2. Another drawback is that it is not possible to track the location of the goods within the warehouse. |

1. Each ID tag is coupled to an asset and is configured to wirelessly communicate with other ID tags in the network within a predetermined proximity. 2. Each tag is also configured to relay communications from other ID tags so that a communication path is established between the RMS and any ID tag in the network, either directly or via other ID tags. |

US20040174260 |

Main applications of RFID

Applications which appeared in analyzed patent records have been listed.

1. Logistics chain management system in Food and pharma industry

2. Global supply chain of semiconductors

3. Supply chain management of High-value electronic items & pharmaceuticals

4. Tracking system

5. Supply chain management

6. Inventory along a distribution chain

7. Asset and materials management system

8. Point-of-sale and point-of-delivery and/or distribution

9. Reusable transportation means

10. Materials handling

11. Commercial enterprise (personnel and asset retention system (PARS))

12. Tracking cargo through customs

13. Supply chain management in Beef industry

The product moves through the global supply chain which involves various stages (places and processes). Next slide indicate the details about the various stages involved in supply chain applications, software applications and hardware used.

Main applications of RFID along with various stages, S/W applications and H/W’s involved

Features cited in analyzed 15 patent records

1. The container can be reprogrammed to include updated logic, updated states, and/or updated expected event information. (US20040246130)

2. The system comprises a truck server and an optional in-truck data communications means, which comprise a digital cell phone or satellite link. (US20040201454)

3. A local computer communicates with the see-through display, information gathering devices, and orientation sensors, optical tracking system, and business applications over one or more networks. (US20040182925)

4. OmniTRACS.RTM., which is a two-way satellite communication system that allows trucks to be monitored and tracked and to allow data communication with dispatchers. (US20040174260)

5. The data report from the reporting software can alert the user as to when the detrimental event occurred and identify the custodian who caused the detrimental event. (US20040049428)

6. Web-based information system for a beef marketing alliance; value-based procurement, and supply chain management. (US20020158765)

7. The software contains a component for determining the best time for an animal to go to slaughter based on a target weight. (US20020158765)

SWOT analysis

| STRENGTHS * Advanced technology * Easy to use * High memory capacity * Small size |

WEAKNESSES * Lack of industry and application standards * High cost per unit and high RFID system costs * Weak market understanding of the benefits of RFID technology |

| OPPORTUNITIES * Could replace the bar code * End-user demand for RFID systems is increasing * Huge market potential in many businesses * Need for standardization |

THREATS * Ethical threats concerning private life * Highly fragmented competitive environment |

Conclusion

It has been observed that selection of RFID tag depend up on the frequency desirable in supply chain application. Industrial attentions is on passive RFID technology. The integration of software technology with electronic identification system will definitely give new dimensions to the supply chain management.