Difference between revisions of "Diamond Tipped Indenting Tool"

From DolceraWiki

Anand.shukla (Talk | contribs) (→Agenda) |

Anand.shukla (Talk | contribs) |

||

| Line 20: | Line 20: | ||

* Has always been at the forefront of technologies for turbine, rocket, reciprocating engines, power systems, etc. | * Has always been at the forefront of technologies for turbine, rocket, reciprocating engines, power systems, etc. | ||

| + | |||

| + | == Utility == | ||

| + | |||

| + | * A Tool using this technology has a diamond at a specified precise orientation affixed to the tip of the shank of the machine Enabling markings on various metal surfaces for | ||

| + | * Identification purposes | ||

| + | * Surface treatment | ||

| + | * Surface condition | ||

| + | |||

| + | * The point of the tool strikes the surface of metal and on impact creates a cold-formed indentation or mark. | ||

| + | |||

| + | == Schematic Representation - Indenting Tool == | ||

| + | [[Image:Schematic Representation-indenter.jpg]] | ||

| + | |||

| + | == Graphical Representation - Tool tip == | ||

| + | [[Image:Graphical Representation indenting tool.jpg|thumb|right|500px]] | ||

| + | |||

| + | * '''Stereographic projection triangle for the diamond crystal''' | ||

| + | Represents a 3D orientation spread out on a 2D plane. | ||

| + | Figure depicts the orientation of the diamond tip. | ||

| + | It Shows the axis of orientation of the diamond crystal w.r.t three standard orientations of the crystal marked by the 3 vertices.The pole of the crystal should lie within the dotted circle to achieve the super wear resistance orientation | ||

| + | |||

| + | == Importance of the orientation == | ||

| + | |||

| + | * Diamond crystals are anisotropic | ||

| + | * Their mechanical and physical properties vary with their crystallographic orientation | ||

| + | * The orientation of the crystal governs its strength and wear resistance | ||

| + | * This particular '''super wear-resistant orientation''' has been discovered and patented by Pratt and Whitney. | ||

| + | |||

| + | == Limitations of other technologies == | ||

| + | |||

| + | * Carbide and non-oriented diamond indenters have problems such as | ||

| + | |||

| + | # Wear and tear of tool head | ||

| + | # Replacement costs | ||

| + | |||

| + | == Advantages of this tool == | ||

| + | |||

| + | * '''Economical''' | ||

| + | # Low replacement costs because of increased tool life (up too 100 times that of carbide tools) | ||

| + | # Reduced cost per mark | ||

| + | |||

| + | * '''Quality''' | ||

| + | # Better reading of 2D markings | ||

| + | # Improved marking reliability and quality | ||

| + | |||

| + | * '''Physical''' | ||

| + | # Improved wear resistance | ||

| + | # Less force required to obtain indention depth | ||

| + | |||

| + | == Applications == | ||

| + | |||

| + | * Aero & Industrial Gas Turbines | ||

| + | * Railway | ||

| + | * Machineries | ||

| + | * Weapon markings | ||

| + | * Punches and Dies | ||

| + | * Cables and Wires | ||

| + | * Weapon markings | ||

| + | * Any metal equipment | ||

Revision as of 01:53, 29 October 2009

Contents

Agenda

- To introduce and explain the benefits of the patented technology developed by Pratt & Whitney.

- To find out interest of the prospects in acquiring the technology on a licensed basis from Pratt & Whitney.

About Dolcera

- Dolcera is an international services firm specializing in intellectual property and market research services. Our clientele includes several fortune 500 companies and global 100 companies. For more information please visit: www.dolcera.com

- We at Dolcera are partnering with Pratt & whitney to out-license their green technology to replace Ni-Cd coatings used for finishing purposes.

About Pratt & Whitney

- Pratt & Whitney is one of the largest aircraft engine manufacturers in the world with a sales revenue of more than $12 Bn and spends more than $250 Mn in research & development.

- Cutting edge R&D with over a 1000 patents.

- Has always been at the forefront of technologies for turbine, rocket, reciprocating engines, power systems, etc.

Utility

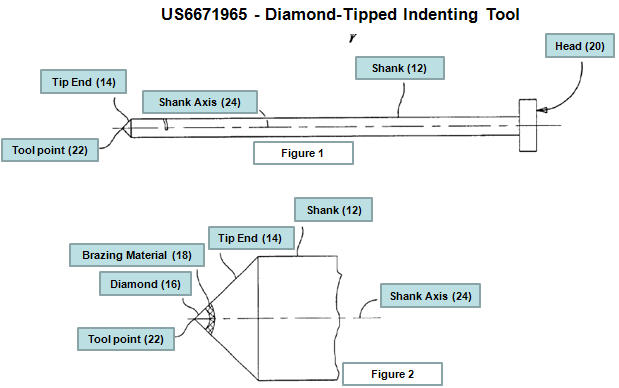

- A Tool using this technology has a diamond at a specified precise orientation affixed to the tip of the shank of the machine Enabling markings on various metal surfaces for

* Identification purposes * Surface treatment * Surface condition

- The point of the tool strikes the surface of metal and on impact creates a cold-formed indentation or mark.

Schematic Representation - Indenting Tool

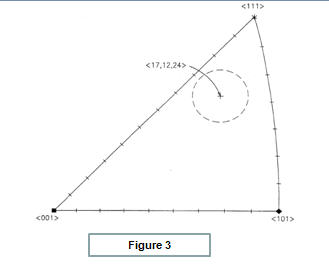

Graphical Representation - Tool tip

- Stereographic projection triangle for the diamond crystal

Represents a 3D orientation spread out on a 2D plane. Figure depicts the orientation of the diamond tip. It Shows the axis of orientation of the diamond crystal w.r.t three standard orientations of the crystal marked by the 3 vertices.The pole of the crystal should lie within the dotted circle to achieve the super wear resistance orientation

Importance of the orientation

- Diamond crystals are anisotropic

- Their mechanical and physical properties vary with their crystallographic orientation

- The orientation of the crystal governs its strength and wear resistance

- This particular super wear-resistant orientation has been discovered and patented by Pratt and Whitney.

Limitations of other technologies

- Carbide and non-oriented diamond indenters have problems such as

- Wear and tear of tool head

- Replacement costs

Advantages of this tool

- Economical

- Low replacement costs because of increased tool life (up too 100 times that of carbide tools)

- Reduced cost per mark

- Quality

- Better reading of 2D markings

- Improved marking reliability and quality

- Physical

- Improved wear resistance

- Less force required to obtain indention depth

Applications

- Aero & Industrial Gas Turbines

- Railway

- Machineries

- Weapon markings

- Punches and Dies

- Cables and Wires

- Weapon markings

- Any metal equipment