Difference between revisions of "Wind Energy"

Crazypaddu (Talk | contribs) (→Taxonomy for Wind Turbines) |

(→Dolcera Dashboard) |

||

| (335 intermediate revisions by 9 users not shown) | |||

| Line 1: | Line 1: | ||

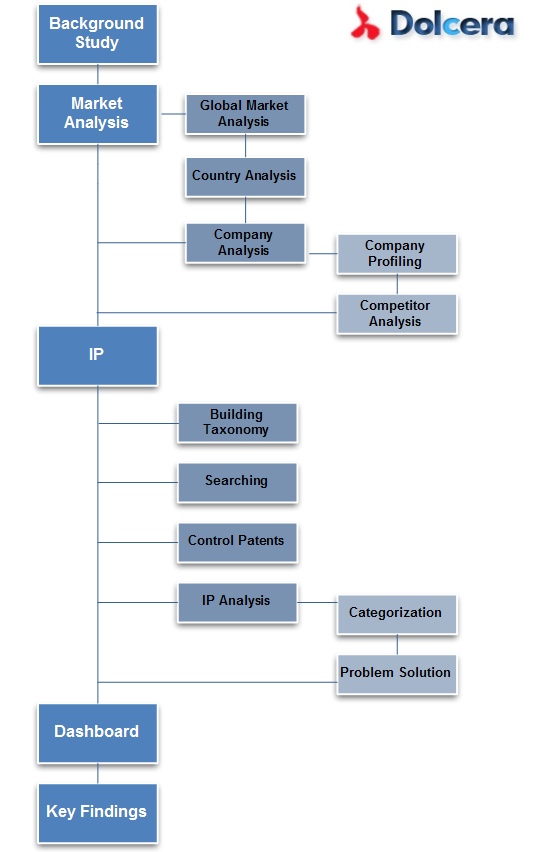

| − | + | This report presents a brief introduction to wind energy and technologies available for horizontal wind turbines. A detailed taxonomy for horizontal axis wind turbines is presented covering parts of the turbine, control systems, applications among others. A detailed landscape analysis of patent and non-patent literature is done with a focus on Doubly-fed Induction Generators (DFIG) used in the horizontal axis wind turbines for efficient power generation. The product information of major players in the market is also captured for Doubly-fed Induction Generators. The final section of the report covers the existing and future market predictions for wind energy-based power generation. | |

| − | + | [[Image:Wind_Flowchart.PNG|right|580px|thumb|Process Flow]] | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| + | <br> | ||

=Introduction= | =Introduction= | ||

| − | * | + | * We have been using wind power at least since 5000 BC to propel sailboats and sailing ships, and architects have used wind-driven natural ventilation in buildings since similarly ancient times. The use of wind to provide mechanical power came later. |

* Harnessing renewable alternative energy is the ideal way to tackle the energy crisis, with due consideration given to environmental pollution, that looms large over the world. | * Harnessing renewable alternative energy is the ideal way to tackle the energy crisis, with due consideration given to environmental pollution, that looms large over the world. | ||

| − | * Renewable energy is also called "clean energy" or "green power" because it doesn’t pollute the air or the water. Wind energy is one such renewable energy source that harnesses natural wind power. | + | * Renewable energy is also called "clean energy" or "green power" because it doesn’t pollute the air or the water. Wind energy is one such renewable energy source that harnesses natural wind power.<br> |

| + | == Read More? == | ||

| + | Click on '''[[Wind Energy Background]]''' to read more about wind energy. | ||

| − | + | In order to overcome the problems associated with fixed speed wind turbine system and to maximize the wind energy capture, many new wind farms are employing variable speed wind energy conversion systems (WECS) with doubly-fed induction generator (DFIG). It is the most popular and widely used scheme for the wind generators due to its advantages. | |

| − | + | For variable-speed systems with limited variable-speed range, e.g. ±30% of synchronous speed, the doubly-fed induction generator(DFIG) can be an interesting solution. This is mainly due to the fact that the power electronic converter only has to handle a fraction (20-30%) of the total power as the converters are connected to the rotor and not to the stator. Therefore, the losses in the power electronic converter can be reduced, compared to a system where the converter has to handle the total power. The overall structure of wind power generation through DFIG as shown in the figure below. | |

| − | + | =Market Research= | |

| − | + | ==The History of Wind Energy== | |

| − | + | ||

| − | + | To read about '''the History of Wind Energy''', '''[http://dolcera.com/wiki/index.php?title=The_History_of_Wind_Energy click here]''' | |

| + | ==Global Wind Energy Market== | ||

| + | ===Market Overview=== | ||

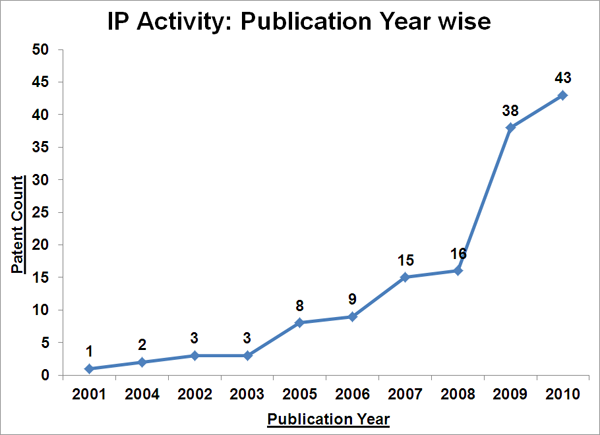

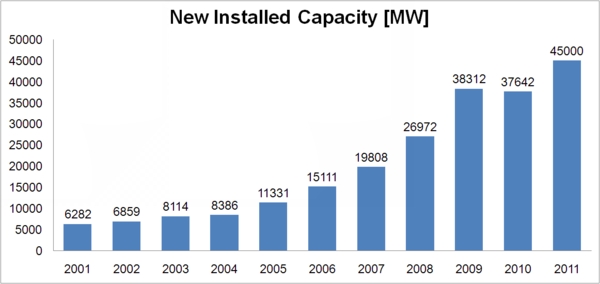

| + | * In the year 2010, the wind capacity reached worldwide '''196’630 Megawatt''', after '''159’050 MW''' in 2009, '''120’903 MW''' in 2008, and '''93’930 MW''' in 2007. | ||

| + | [[Image:World_Installed2.PNG|center|600px|thumb|Source: [http://www.wwindea.org/home/images/stories/pdfs/worldwindenergyreport2010_s.pdf World Wind Energy Report, 2010]]] | ||

| + | * Wind power showed a growth rate of '''23.6 %''', the lowest growth since 2004 and the second lowest growth of the past decade. | ||

| + | * For the first time in more than two decades, the market for new wind turbines was smaller than in the previous year and reached an overall size of '''37’642 MW''', after 38'312 MW in 2009. | ||

| + | [[Image:New.PNG|center|600px|thumb|Source: [http://www.wwindea.org/home/images/stories/pdfs/worldwindenergyreport2010_s.pdf World Wind Energy Report, 2010]]] | ||

| + | * All wind turbines installed by the end of 2010 worldwide can generate '''430 Tera watt hours per annum''', more than the total electricity demand of the United Kingdom, the sixth largest economy of the world, and equaling 2.5 % of the global electricity consumption. | ||

| + | * In the year 2010, altogether '''83 countries''', one more than in 2009, used wind energy for electricity generation. 52 countries increased their total installed capacity, after 49 in the previous year. | ||

| + | * The turnover of the wind sector worldwide reached '''40 billion Euros (55 billion US$) in 2010''', after 50 billion Euros (70 billion US$) in the year 2009. The decrease is due to lower prices for wind turbines and a shift towards China. | ||

| + | * China became number one in total installed capacity and the center of the international wind industry, and added '''18’928 Megawatt''' within one year, accounting for more than 50 % of the world market for new wind turbines. | ||

| + | * The wind sector in 2010 employed '''670’000 persons''' worldwide. | ||

| + | * Nuclear disaster in Japan and oil spill in Gulf of Mexico will have long-term impact on the prospects of wind energy. Governments need to urgently reinforce their wind energy policies. | ||

| + | * WWEA sees a global capacity of '''600’000 Megawatt''' as possible by the year 2015 and more than '''1’500’000 Megawatt''' by the year 2020. | ||

| − | + | Source: [http://www.wwindea.org/home/images/stories/pdfs/worldwindenergyreport2010_s.pdf World Wind Energy Report, 2010] | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

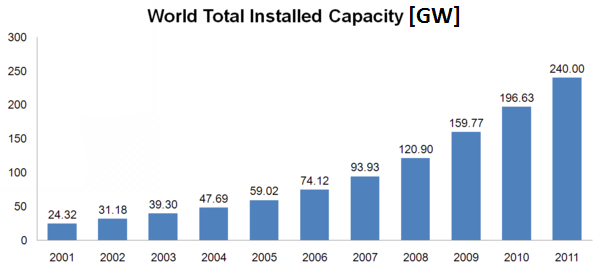

| − | + | ===Global Market Forecast=== | |

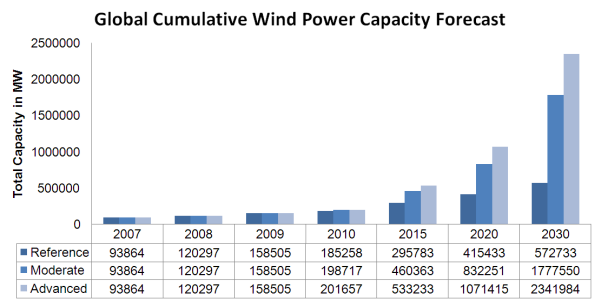

| + | * Global Wind Energy Outlook 2010, provides forecast under [http://dolcera.com/wiki/index.php?title=Forecast_Scenarios three different scenarios] - Reference, Moderate and Advanced. | ||

| + | * The Global Cumulative Wind Power Capacity is estimated to reach 572,733 MW by the year 2030, under the Reference Scenario | ||

| + | * The Global Cumulative Wind Power Capacity is estimated to reach 1,777,550 MW by the year 2030, under the Moderate Scenario | ||

| + | * The Global Cumulative Wind Power Capacity is estimated to reach 2,341,984 MW by the year 2030, under the Advanced Scenario | ||

| + | * The following chart shows the Global Cumulative Wind Power Capacity Forecast,under the different scenarios: | ||

| − | Source:[http://www. | + | [[Image:Global_Forecast.PNG|center|1080px|thumb|Global Cumulative Wind Power Capacity Forecast, Source: [http://www.gwec.net/fileadmin/documents/Publications/GWEO%202010%20final.pdf Global Wind Energy Outlook 2010]]] |

| − | |||

| − | |||

| − | + | Source: [http://www.gwec.net/fileadmin/documents/Publications/GWEO%202010%20final.pdf Global Wind Energy Outlook 2010] | |

| − | + | ===Market Growth Rates=== | |

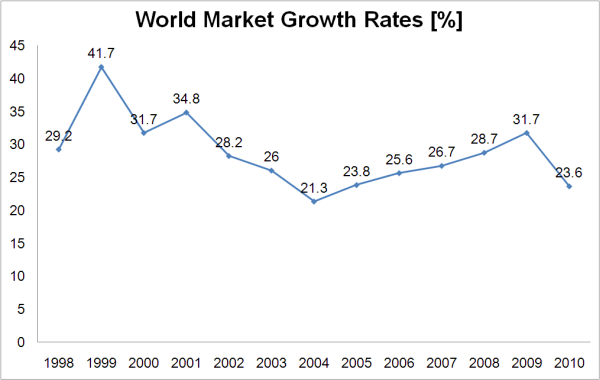

| + | * The growth rate is the relation between the new installed wind power capacity and the installed capacity of the previous year. | ||

| + | * With '''23.6 %''', the year 2010 showed the second lowest growth rate of the last decade. | ||

| − | + | [[Image:World_Market_Growth Rates.PNG|center|600px|thumb|World Market Growth Rates, Source: [http://www.wwindea.org/home/images/stories/pdfs/worldwindenergyreport2010_s.pdf World Wind Energy Report, 2010]]] | |

| − | + | ||

| − | + | * Before 2010, the annual growth rate had continued to increase since the year 2004, '''peaking in 2009 at 31.7%''', the highest rate since 2001. | |

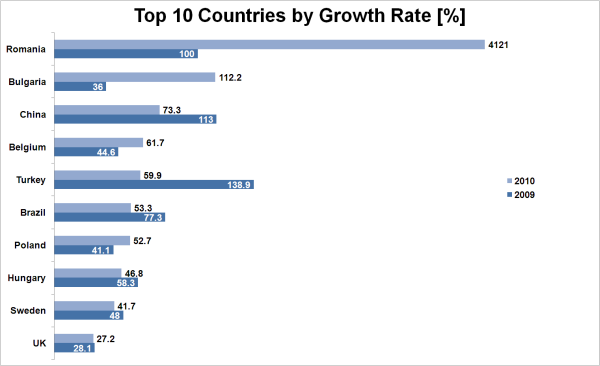

| − | + | * The highest growth rates of the year 2010 by country can be found in '''Romania''', which increased its capacity by 40 times. | |

| − | + | * The second country with a growth rate of more than 100 % was '''Bulgaria (112%)'''. | |

| − | + | * In the year 2009, four major wind markets had more than doubled their wind capacity: '''China, Mexico, Turkey, and Morocco'''. | |

| − | + | * Next to China, strong growth could be found mainly in '''Eastern European and South Eastern European''' countries: Romania, Bulgaria, Turkey, Lithuania, Poland, Hungary, Croatia and Cyprus, and Belgium. | |

| − | + | * Africa (with the exception of Egypt and Morocco) and Latin America (with the exception of Brazil), are again lagging behind the rest of the world in the commercial use of wind power. | |

| − | * | + | * The Top 10 countries by Growth Rate are shown in the figure listed below (only markets bigger than 200 MW have been considered): |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | * | + | |

| − | * | + | |

| − | * | + | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | Source:[http://www. | + | [[Image:Top_Growth_Countries.PNG|center|600px|thumb|Top Countries by Market Growth Rates, Source: [http://www.wwindea.org/home/images/stories/pdfs/worldwindenergyreport2010_s.pdf World Wind Energy Report, 2010]]] |

| − | = | + | ==Geographical Market Distribution== |

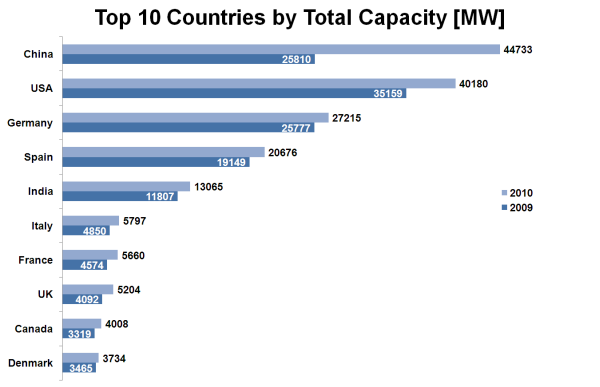

| + | * China became number one in total installed capacity and the center of the international wind industry, and added '''18'928 Megawatt''' within one year, accounting for more than 50 % of the world market for new wind turbines. | ||

| + | * Major decrease in new installations can be observed in North America and the '''USA lost its number one position''' in total capacity to China. | ||

| + | * Many Western European countries are showing stagnation, whereas there is strong growth in a number of Eastern European countries. | ||

| + | * '''Germany''' keeps its number one position in Europe with '''27'215 Megawatt''', followed by Spain with 20'676 Megawatt. | ||

| + | * The highest shares of wind power can be found in three European countries: '''Denmark (21.0%), Portugal (18.0 %) and Spain (16.0%)'''. | ||

| + | * '''Asia''' accounted for the largest share of new installations '''(54.6%)''', followed by '''Europe (27.0%)''' and '''North America (16.7 %)'''. | ||

| + | * '''Latin America (1.2%)''' and '''Africa (0.4%)''' still played only a marginal role in new installations. | ||

| + | * Africa: North Africa represents still lion share of installed capacity, wind energy plays hardly a role yet in Sub-Sahara Africa. | ||

| + | * Nuclear disaster in Japan and oil spill in Gulf of Mexico will have long-term impact on the prospects of wind energy. Governments need to urgently reinforce their wind energy policies. | ||

| − | [ | + | Source: [http://www.wwindea.org/home/images/stories/pdfs/worldwindenergyreport2010_s.pdf World Wind Energy Report, 2010] |

| + | The regional breakdowns for the period 2009-2030 has been provided for the following three scenarios: | ||

| + | ;# [[Regional Breakdown: Reference scenario (GWEO 2010)]] | ||

| + | ;# [[Regional Breakdown: Moderate scenario (GWEO 2010)]] | ||

| + | ;# [[Regional Breakdown: Advanced scenario (GWEO 2010)]] | ||

| − | + | ''Note: To know more about the '''Forecast Scenarios''' [http://dolcera.com/wiki/index.php?title=Forecast_Scenarios click here]'' | |

| − | + | ==Country-wise Market Distribution== | |

| − | + | * In 2010, the Chinese wind market represented more than half of the world market for new wind turbines adding '''18.9 GW''', which equals a market share of '''50.3%'''. | |

| + | * A sharp decrease in new capacity happened in the USA whose share in new wind turbines fell down to '''14.9% (5.6 GW)''', after 25.9% or 9.9 GW in | ||

| + | the year 2009. | ||

| + | * '''Nine further countries''' could be seen as major markets, with turbine sales in a range '''between 0.5 and 1.5 GW''': Germany, Spain, India, United | ||

| + | Kingdom, France, Italy, Canada, Sweden and the Eastern European newcomer Romania. | ||

| + | * Further, '''12 markets''' for new turbines had a medium size '''between 100 and 500 MW''': Turkey, Poland, Portugal, Belgium, Brazil, Denmark, Japan, Bulgaria, Greece, Egypt, Ireland, and Mexico. | ||

| + | * By end of 2010, '''20 countries''' had installations of '''more than 1 000 MW''', compared with 17 countries by end of 2009 and 11 countries byend of 2005. | ||

| + | * Worldwide, '''39 countries''' had wind farms with '''a capacity of 100 Megawatt''' or more installed, compared with 35 countries one year ago, and 24 countries five years ago. | ||

| + | * The top five countries (USA, China, Germany, Spain and India) represented '''74.2%''' of the worldwide wind capacity, significantly more than 72.9 % in the year. | ||

| + | * The '''USA and China''' together represented '''43.2%''' of the global wind capacity (up from 38.4 % in 2009). | ||

| + | * The newcomer on the list of countries using wind power commercially is a Mediterranean country, '''Cyprus''', which for the first time installed a larger grid-connected wind farm, with 82 MW. | ||

| − | + | Source: [http://www.wwindea.org/home/images/stories/pdfs/worldwindenergyreport2010_s.pdf World Wind Energy Report, 2010] | |

| − | [ | + | |

| − | + | The top 10 countries by Total Installed Capacity for the year 2010, is illustrated in the chart below: | |

| + | [[Image:Top_Installed_Countries.PNG|center|600px|thumb|Top Countries by Market Growth Rates, Source: [http://www.wwindea.org/home/images/stories/pdfs/worldwindenergyreport2010_s.pdf World Wind Energy Report, 2010]]] | ||

| − | + | To view the Top 10 countries by different other parameters for the year 2010, click on the links below: | |

| + | ;# [[Top 10 countries by Total New Installed Capacity]] | ||

| + | ;# [[Top 10 countries by Capacity per Capita (kW/cap)]] | ||

| + | ;# [[Top 10 countries by Capacity per Land Area (kW/sq. km)]] | ||

| + | ;# [[Top 10 countries by Capacity per GDP (kW/ million USD)]] | ||

| − | + | To view the '''[[Country-wise Installed Wind Power Capacity]]''' (MW) 2002-2010 (Source: World Wind Energy Association), '''[http://dolcera.com/wiki/index.php?title=Country-wise_Installed_Wind_Power_Capacity click here]''' | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ==Country Profiles== | |

| − | + | ===China=== | |

| − | + | <br>'''Wind Energy Outlook for China - 2011 & Beyond''' | |

| − | + | <br>Despite its rapid and seemingly unhampered expansion, the | |

| − | + | Chinese wind power sector continues to face significant | |

| + | challenges, including issues surrounding grid access and | ||

| + | integration, reliability of turbines and a coherent strategy for | ||

| + | developing China’s offshore wind resource. These issues will | ||

| + | be prominent during discussions around the twelfth Five-Year | ||

| + | Plan, which will be passed in March 2011. According to the | ||

| + | draft plan, this is expected to reflect the Chinese | ||

| + | government’s continuous and reinforced commitment to | ||

| + | wind power development, with national wind energy targets | ||

| + | of 90 GW for 2015 and 200 GW for 2020. | ||

| − | + | For a detailed country profile of China please visit this [[China Wind Energy Profile Link]] | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ===India=== | |

| − | + | <br>'''Wind Energy Main market developments in 2010''' | |

| − | + | <br>Today the Indian market is emerging as one of the major | |

| − | < | + | manufacturing hubs for wind turbines in Asia. Currently, |

| − | + | seventeen manufacturers have an annual production capacity | |

| + | of 7,500 MW. According to the WISE, the annual wind turbine | ||

| + | manufacturing capacity in India is likely to exceed | ||

| + | 17,000 MW by 2013. | ||

| + | <br>The Indian market is expanding with the leading wind | ||

| + | companies like Suzlon, Vestas, Enercon, RRB Energy and GE | ||

| + | now being joined by new entrants like Gamesa, Siemens, and | ||

| + | WinWinD, all vying for a greater market share. Suzlon, however, | ||

| + | is still the market leader with a market share of over 50%. | ||

| + | <br>The Indian wind industry has not been significantly affected | ||

| + | by the financial and economic crises. Even in the face of a | ||

| + | global slowdown, the Indian annual wind power market has | ||

| + | grown by almost 68%. However, it needs to be pointed out | ||

| + | that the strong growth in 2010 might have been stimulated | ||

| + | by developers taking advantage of the accelerated | ||

| + | depreciation before this option is phased out. | ||

| − | + | For a detailed country profile of India please visit this [[India Wind Energy Profile Link]] | |

| − | + | ||

| − | + | ==Market Share Analysis== | |

| + | ===Global Market Share=== | ||

| + | * Vestas leads the Global Market in the 2010 with a 12% market share according to Make Consulting, while BTM Consulting reports it to have a 14.8% market share. | ||

| + | * According to Make Consulting, the global market share of Vestas has decreased from 19% in 2008, to 14.5% in 2009, to 12% in 2010. | ||

| + | * According to BTM Consulting, the global market share of Vestas has changed from 19% in 2008, to 12% in 2009, to 14.8% in 2010. | ||

| + | * According to Make Consulting, the global market share of GE Energy has decreased from 18% in 2008, to 12.5% in 2009, to 10% in 2010. | ||

| + | * The market share of world no. 2 Sinovel, has been constantly increasing, from 5% in 2008 , to 9.3% in 2009, to 11% in 2010 | ||

| + | * The top 5 companies have been occupying more than half of the Global Market Share from 2008 to 2010 | ||

| − | + | Source: [http://www.make-consulting.com Make Consulting], [http://www.btmgcs.com/ BTM Global Consulting] | |

| − | + | The chart given below illustrates the Global Market Share Comparison of Major Wind Energy Companies for the period 2008-2010, as provided by two different agencies, Make Consulting and BTM Consulting: | |

| − | | | + | [[Image:Market_Share_Comparison.JPG|center|1080px|thumb|Global Market Share Comparison of Major Companies for the period 2008-2010 |

| − | | | + | , Source: [http://www.make-consulting.com Make Consulting], [http://www.btmgcs.com/ BTM Global Consulting]]] |

| − | + | ===Market Share - Top 10 Markets=== | |

| − | + | * While Vestas is the Global Leader, it is the leader in only one of Top 10 markets, which is 10<sup>th</sup> placed Sweden | |

| − | + | * But, Vestas is ranked 2<sup>nd</sup> in 5 of Top 10 markets | |

| − | + | * Sinovel, ranked 2<sup>nd</sup> globally, features only once in the Top 3 Companies list in the Top 10 markets, but scores globally because it leads the largest market China | |

| − | + | * The table given below illustrates the Top 3 players in Top 10 Wind Energy Markets of the world: | |

| − | + | {|border="2" cellspacing="0" cellpadding="4" width="50%" align="center" | |

| − | + | |bgcolor = "#4F81BD"|<font color="#FFFFFF">'''Market'''</font> | |

| − | + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''MW'''</font> | |

| − | + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''No. 1'''</font> | |

| − | + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''No. 2'''</font> | |

| − | + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''No. 3'''</font> | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | * | + | |

| − | The | + | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | {|border="2" cellspacing="0" cellpadding="4" width=" | + | |

| − | + | ||

| − | |align = "center" bgcolor = "# | + | |

| − | |align = "center" bgcolor = "# | + | |

| − | |align = "center" bgcolor = "# | + | |

| − | |align = "center" bgcolor = "# | + | |

|- | |- | ||

| − | | | + | |bgcolor = "#DBE5F1"|'''China''' |

| − | | | + | |align = "center" bgcolor = "#DBE5F1"|18928 |

| − | + | |align = "center" bgcolor = "#DBE5F1"|Sinovel | |

| − | + | |align = "center" bgcolor = "#DBE5F1"|Goldwind | |

| − | | | + | |align = "center" bgcolor = "#DBE5F1"|Dongfang |

| − | + | ||

| − | + | ||

| − | | | + | |

| − | + | ||

| − | | | + | |

| − | + | ||

|- | |- | ||

| − | | | + | |bgcolor = "#DBE5F1"|'''USA''' |

| − | + | |align = "center" bgcolor = "#DBE5F1"|5115 | |

| − | = | + | |align = "center" bgcolor = "#DBE5F1"|GE Energy |

| − | + | |align = "center" bgcolor = "#DBE5F1"|Vestas | |

| − | + | |align = "center" bgcolor = "#DBE5F1"|Siemens | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | | align = "center" bgcolor = "# | + | |

| − | | align = "center" bgcolor = "# | + | |

| − | | align = "center" bgcolor = "# | + | |

|- | |- | ||

| − | | align = "center" bgcolor = "# | + | |bgcolor = "#DBE5F1"|'''India''' |

| − | | align = "center"| | + | |align = "center" bgcolor = "#DBE5F1"|2139 |

| − | | | + | |align = "center" bgcolor = "#DBE5F1"|Suzlon |

| + | |align = "center" bgcolor = "#DBE5F1"|Enercon | ||

| + | |align = "center" bgcolor = "#DBE5F1"|Vestas | ||

|- | |- | ||

| − | | align = "center" bgcolor = "# | + | |bgcolor = "#DBE5F1"|'''Germany''' |

| − | | align = "center"| | + | |align = "center" bgcolor = "#DBE5F1"|1551 |

| − | | | + | |align = "center" bgcolor = "#DBE5F1"|Enercon |

| + | |align = "center" bgcolor = "#DBE5F1"|Vestas | ||

| + | |align = "center" bgcolor = "#DBE5F1"|Suzlon | ||

|- | |- | ||

| − | | align = "center" bgcolor = "# | + | |bgcolor = "#DBE5F1"|'''UK''' |

| − | | align = "center"| | + | |align = "center" bgcolor = "#DBE5F1"|1522 |

| − | | | + | |align = "center" bgcolor = "#DBE5F1"|Siemens |

| + | |align = "center" bgcolor = "#DBE5F1"|Vestas | ||

| + | |align = "center" bgcolor = "#DBE5F1"|Gamesa | ||

|- | |- | ||

| − | | align = "center" bgcolor = "# | + | |bgcolor = "#DBE5F1"|'''Spain''' |

| − | | align = "center"| | + | |align = "center" bgcolor = "#DBE5F1"|1516 |

| − | | | + | |align = "center" bgcolor = "#DBE5F1"|Gamesa |

| + | |align = "center" bgcolor = "#DBE5F1"|Vestas | ||

| + | |align = "center" bgcolor = "#DBE5F1"|GE Energy | ||

|- | |- | ||

| − | |align = "center" bgcolor = "# | + | |bgcolor = "#DBE5F1"|'''France''' |

| − | |align = "center"| | + | |align = "center" bgcolor = "#DBE5F1"|1186 |

| − | | | + | |align = "center" bgcolor = "#DBE5F1"|Enercon |

| + | |align = "center" bgcolor = "#DBE5F1"|Suzlon | ||

| + | |align = "center" bgcolor = "#DBE5F1"|Vestas | ||

|- | |- | ||

| − | | align = "center" bgcolor = "# | + | |bgcolor = "#DBE5F1"|'''Italy''' |

| − | | align = "center"| | + | |align = "center" bgcolor = "#DBE5F1"|948 |

| − | | | + | |align = "center" bgcolor = "#DBE5F1"|Gamesa |

| + | |align = "center" bgcolor = "#DBE5F1"|Vestas | ||

| + | |align = "center" bgcolor = "#DBE5F1"|Suzlon | ||

|- | |- | ||

| − | | align = "center" bgcolor = "# | + | |bgcolor = "#DBE5F1"|'''Canada''' |

| − | | align = "center"| | + | |align = "center" bgcolor = "#DBE5F1"|690 |

| − | | | + | |align = "center" bgcolor = "#DBE5F1"|Siemens |

| + | |align = "center" bgcolor = "#DBE5F1"|GE Energy | ||

| + | |align = "center" bgcolor = "#DBE5F1"|Enercon | ||

|- | |- | ||

| − | | align = "center" bgcolor = "# | + | |bgcolor = "#DBE5F1"|'''Sweeden''' |

| − | | align = "center"| | + | |align = "center" bgcolor = "#DBE5F1"|604 |

| − | | | + | |align = "center" bgcolor = "#DBE5F1"|Vestas |

| + | |align = "center" bgcolor = "#DBE5F1"|Enercon | ||

| + | |align = "center" bgcolor = "#DBE5F1"|Siemens | ||

|- | |- | ||

| − | | align = "center" bgcolor = "# | + | |align = "center" bgcolor = "#DBE5F1" colspan = "5"|''Source: BTM Consult - part of Navigant Consulting - March 2011'' |

| − | + | ||

| − | + | ||

|- | |- | ||

| − | | | + | |}<br clear="all"> |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | Source: [http://www.btm.dk/reports/world+market+update+2010 BTM Consult] | |

| − | + | ||

| − | = | + | ==Company Profiles== |

| − | + | ||

| − | ''' | + | # '''[[Vestas Wind Systems A/S]]''' |

| − | + | # '''[[Suzlon Energy]]''' | |

| − | | | + | |

| + | ==Major Wind Turbine Suppliers== | ||

| + | {|border="2" cellspacing="0" cellpadding="4" width="50%" align="center" | ||

| + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''Turbine maker'''</font> | ||

| + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''Rotor blades'''</font> | ||

| + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''Gear boxes'''</font> | ||

| + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''Generators'''</font> | ||

| + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''Towers'''</font> | ||

| + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''Controllers'''</font> | ||

|- | |- | ||

| − | | | + | |bgcolor = "#DBE5F1"|Vestas |

| − | | | + | |bgcolor = "#DBE5F1"|Vestas, LM |

| − | | | + | |bgcolor = "#DBE5F1"|Bosch Rexroth, Hansen, Wingery, Moventas |

| + | |bgcolor = "#DBE5F1"| Weier, Elin, ABB, LeroySomer | ||

| + | |bgcolor = "#DBE5F1"| Vestas, NEG, DMI | ||

| + | |bgcolor = "#DBE5F1"|Cotas (Vestas),<br>NEG (Dancontrol) | ||

|- | |- | ||

| − | | | + | |bgcolor = "#DBE5F1"|GE energy |

| − | | | + | |bgcolor = "#DBE5F1"|LM, Tecsis |

| − | | | + | |bgcolor = "#DBE5F1"|Wingery, Bosch, Rexroth, Eickhoff, GE |

| + | |bgcolor = "#DBE5F1"|Loher, GE | ||

| + | |bgcolor = "#DBE5F1"|DMI, Omnical, SIAG | ||

| + | |bgcolor = "#DBE5F1"|GE | ||

|- | |- | ||

| − | | | + | |bgcolor = "#DBE5F1"|Gamesa |

| − | | | + | |bgcolor = "#DBE5F1"|Gamesa, LM |

| − | | | + | |bgcolor = "#DBE5F1"| Echesa (Gamesa), Winergy, Hansen |

| + | |bgcolor = "#DBE5F1"|Indar (Gamesa), Cantarey | ||

| + | |bgcolor = "#DBE5F1"|Gamesa | ||

| + | |bgcolor = "#DBE5F1"| Ingelectric (Gamesa) | ||

|- | |- | ||

| − | | | + | |bgcolor = "#DBE5F1"|Enercon |

| − | + | |bgcolor = "#DBE5F1"|Enercon | |

| − | + | |bgcolor = "#DBE5F1"|Direct drive | |

| − | + | |bgcolor = "#DBE5F1"|Enercon | |

| − | + | |bgcolor = "#DBE5F1"|KGW, SAM | |

| − | + | |bgcolor = "#DBE5F1"|Enercon | |

| − | + | ||

| − | + | ||

| − | |bgcolor = "# | + | |

| − | |bgcolor = "# | + | |

| − | |bgcolor = "# | + | |

| − | |bgcolor = "# | + | |

| − | |bgcolor = "# | + | |

| − | + | ||

|- | |- | ||

| − | | | + | |bgcolor = "#DBE5F1"| Siemens<br>wind |

| − | | | + | |bgcolor = "#DBE5F1"|Siemens, LM |

| − | | | + | |bgcolor = "#DBE5F1"|Winergy |

| − | | | + | |bgcolor = "#DBE5F1"|ABB |

| − | | | + | |bgcolor = "#DBE5F1"|Roug, KGW |

| − | + | |bgcolor = "#DBE5F1"| Siemens, KK Electronic | |

|- | |- | ||

| − | | | + | |bgcolor = "#DBE5F1"|Suzlon |

| − | | | + | |bgcolor = "#DBE5F1"|Suzlon |

| − | | | + | |bgcolor = "#DBE5F1"|Hansen, Winergy |

| − | | | + | |bgcolor = "#DBE5F1"| Suzlon,<br>Siemens |

| − | | | + | |bgcolor = "#DBE5F1"|Suzlon |

| − | + | |bgcolor = "#DBE5F1"| Suzlon, Mita Teknik | |

|- | |- | ||

| − | | | + | |bgcolor = "#DBE5F1"|Repower |

| − | | | + | |bgcolor = "#DBE5F1"|LM |

| − | | | + | |bgcolor = "#DBE5F1"| Winergy, Renk, Eickhoff |

| − | | | + | |bgcolor = "#DBE5F1"|N/A |

| − | | | + | |bgcolor = "#DBE5F1"|N/A |

| − | + | |bgcolor = "#DBE5F1"| Mita Teknik, ReGuard | |

|- | |- | ||

| − | | | + | |bgcolor = "#DBE5F1"|Nordex |

| − | | | + | |bgcolor = "#DBE5F1"|Nordex |

| − | | | + | |bgcolor = "#DBE5F1"| Winergy, Eickhoff, Maag |

| − | | | + | |bgcolor = "#DBE5F1"|Loher |

| − | | | + | |bgcolor = "#DBE5F1"| Nordex, Omnical |

| − | + | |bgcolor = "#DBE5F1"| Nordex, Mita Teknik | |

| + | |- | ||

| + | |align = "center" bgcolor = "#DBE5F1" colspan = "6"|''Source: BTM Consult'' | ||

|- | |- | ||

| − | | | + | |}<br clear="all"> |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| + | ==Products of Top Companies== | ||

| + | {|border="2" cellspacing="0" cellpadding="4" width="100%" | ||

| + | |align = "center" bgcolor = "#4F81BD" width=”42”|<font color="#FFFFFF">'''S.No.'''</font> | ||

| + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''Company'''</font> | ||

| + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''Product'''</font> | ||

| + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''Specifications'''</font> | ||

| + | |-valign="top" | ||

| + | |align = "center" bgcolor = "#DCE6F1"|1 | ||

| + | |bgcolor = "#DCE6F1"|<font color="#0000FF"><u>[http://www.vestas.com/en/wind-power-plants/procurement/turbine-overview/v80-2.0-mw.aspx#/vestas-univers Vestas]</u></font> | ||

| + | |bgcolor = "#DCE6F1"|V80 | ||

| + | |bgcolor = "#DCE6F1"|'''Rated Power: '''2.0 MW, '''Frequency:''' 50 Hz/60 Hz, '''Number of Poles:''' 4-pole, '''Operating Temperature: -'''30°C to 40° | ||

| + | |- valign="top" | ||

| + | |align = "center"|2 | ||

| + | |<font color="#0000FF"><u>[http://www.vestas.com/en/wind-power-plants/procurement/turbine-overview/v80-2.0-mw.aspx#/vestas-univers Vestas]</u></font> | ||

| + | |V90 | ||

| + | |'''Rated Power:''' 1.8/2.0 MW, '''Frequency :''' 50 Hz/60 Hz, '''Number of Poles :''' 4-pole(50 Hz)/6-pole(60 Hz), '''Operating Temperature: -'''30°C to 40° | ||

| + | |- valign="top" | ||

| + | |align = "center" bgcolor = "#DCE6F1"|3 | ||

| + | |bgcolor = "#DCE6F1"|<font color="#0000FF"><u>[http://www.vestas.com/en/wind-power-plants/procurement/turbine-overview/v80-2.0-mw.aspx#/vestas-univers Vestas]</u></font> | ||

| + | |bgcolor = "#DCE6F1"|V90 Offshore | ||

| + | |bgcolor = "#DCE6F1"|'''Rated Power:''' 3.0 MW, '''Frequency:''' 50 Hz/60 Hz, '''Number of Poles:''' 4-pole, '''Operating Temperature: '''-30°C to 40° | ||

| + | |- valign="top" | ||

| + | |align = "center"|4 | ||

| + | |<font color="#0000FF"><u>[http://www.china-windturbine.com/news/doubly_wind_turbines.htm North Heavy Company]</u></font> | ||

| + | |2 MW DFIG | ||

| + | |'''Rated Power:''' 2.0 MW, '''Rated Voltage:''' 690V, '''Rated Current:''' 1670A, '''Frequency:''' 50Hz, '''Number of Poles :''' 4-pole, '''Rotor Rated Voltage:''' 1840V, '''Rotor Rated Current''' 670A, '''Rated Speed:''' 1660rpm;''' Power Speed Range: '''520-1950 rpm, '''Insulation Class:''' H, '''Protection Class:''' IP54, '''Motor Temperature Rise''' =<nowiki><</nowiki>95K | ||

| + | |- valign="top" | ||

| + | |align = "center" bgcolor = "#DCE6F1"|5 | ||

| + | |bgcolor = "#DCE6F1"|<font color="#0000FF"><u>[http://docs.google.com/viewer?a=v&q=cache:X9KReq0YEigJ:www.iberdrolarenewables.us/bluecreek/docs/primary/03-Appendices/_Q-Brochure-of-G-90-Turbine/Brochure-G-90-Turbine.pdf+gamesa+g90&hl=en&pid=bl&srcid=ADGEESgldaLogi1i5Pg71zE-FO_AMqbeKL5wJiA8LVklgq5ev2in Gamesa]</u></font> | ||

| + | |bgcolor = "#DCE6F1"|G90 | ||

| + | |bgcolor = "#DCE6F1"|'''Rated Voltage:''' 690 V, '''Frequency:''' 50 Hz, '''Number of Poles:''' 4, '''Rotational Speed:''' 900:1,900 rpm (rated 1,680 rpm) (50Hz); '''Rated Stator Current: '''1,500 A @ 690 V, '''Protection Class:''' IP 54, '''Power Factor(standard):''' 0.98 CAP - 0.96 IND at partial loads and 1 at nominal power, '''Power Factor(Optional):''' 0.95 CAP - 0.95 IND throughout the power range | ||

| + | |- valign="top" | ||

| + | |align = "center"|6 | ||

| + | |<font color="#0000FF"><u>[http://www.nordex-online.com/en/products-services/wind-turbines/n100-25-mw Nordex]</u></font> | ||

| + | | N80 | ||

| + | |'''Rated Power:''' 2.5 MW, '''Rated Voltage:''' 690V, '''Frequency:''' 50/60Hz, '''Cooling Systems:''' liquid/air | ||

| + | |- valign="top" | ||

| + | |align = "center" bgcolor = "#DCE6F1"|7 | ||

| + | |bgcolor = "#DCE6F1"|<font color="#0000FF"><u>[http://www.nordex-online.com/en/products-services/wind-turbines/n100-25-mw Nordex]</u></font> | ||

| + | |bgcolor = "#DCE6F1"| N90 | ||

| + | |bgcolor = "#DCE6F1"|'''Rated Power:''' 2.5 MW, '''Rated Voltage: '''690V,''' Frequency: '''50/60Hz,''' Cooling Systems: '''liquid/air | ||

| + | |- valign="top" | ||

| + | |align = "center"|8 | ||

| + | |<font color="#0000FF"><u>[http://www.nordex-online.com/en/products-services/wind-turbines/n100-25-mw Nordex]</u></font> | ||

| + | |N100 | ||

| + | |'''Rated Power:''' 2.4 MW, '''Rated Voltage: '''690V, '''Frequency: '''50/60Hz, '''Cooling Systems: '''liquid/air | ||

| + | |- valign="top" | ||

| + | |align = "center" bgcolor = "#DCE6F1"|9 | ||

| + | |bgcolor = "#DCE6F1"|<font color="#0000FF"><u>[http://www.nordex-online.com/en/products-services/wind-turbines/n100-25-mw Nordex]</u></font> | ||

| + | |bgcolor = "#DCE6F1"| N117 | ||

| + | |bgcolor = "#DCE6F1"|'''Rated Power:''' 2.5 MW, '''Rated Voltage: '''690V, '''Frequency: '''50/60Hz, '''Cooling Systems: '''liquid/air | ||

| + | |- valign="top" | ||

| + | |align = "center"|10 | ||

| + | |<font color="#0000FF"><u>[http://www.converteam.com/majic/pageServer/1704040148/en/index.html Converteam]</u></font> | ||

| + | |DFIG | ||

| + | |NA | ||

| + | |- valign="top" | ||

| + | |align = "center" bgcolor = "#DCE6F1"|11 | ||

| + | |bgcolor = "#DCE6F1"|<font color="#0000FF"><u>[http://geoho.en.alibaba.com/product/252321923-0/1_5MW_doubly_fed_asynchronous_generator.html Xian Geoho Energy Technology]</u></font> | ||

| + | |bgcolor = "#DCE6F1"|1.5MW DFIG | ||

| + | |bgcolor = "#DCE6F1"|'''Rated Power:''' 1550KW, '''Rated Voltage: '''690V, '''Rated Speed: '''1755 r/min, '''Speed Range: '''975<nowiki>~</nowiki>1970 r/min, '''Number of Poles: '''4-pole, '''Stator Rated Voltage: '''690V±10%, '''Stator Rated Current: '''1115A; '''Rotor Rated Voltage: '''320V, '''Rotor Rated Current: '''430A, '''Winding Connection: '''Y / Y, '''Power Factor: '''0.95(Lead) <nowiki>~</nowiki> 0.95Lag,''' Protection Class: '''IP54, '''Insulation Class: '''H, '''Work Mode: '''S1, '''Installation ModeI: '''M B3, '''Cooling Mode: '''Air cooling, '''Weight: '''6950kg | ||

| + | |- valign="top" | ||

| + | |align = "center"|12 | ||

| + | |<font color="#0000FF"><u>[http://www.tecowestinghouse.com/products/custom_engineered/DF_WR_ind_generator.html Tecowestinghouse]</u></font> | ||

| + | |TW450XX (0.5-1 KW) | ||

| + | |'''Rated Power:''' 0.5 -1 KW, '''Rated Voltage: '''460/ 575/ 690 V, '''Frequency: '''50/ 60 Hz, '''Number of Poles: '''4/6,''' Ambient Temp.(°C): -'''40 to 50, '''Speed Range (% of Synch. Speed): '''68% to 134%, '''Power Factor (Leading): -'''0.90 to <nowiki>+</nowiki>0.90 , '''Insulation Class: '''H/F, '''Efficiency: '''<nowiki>></nowiki>= 96% | ||

| + | |- valign="top" | ||

| + | |align = "center" bgcolor = "#DCE6F1"|13 | ||

| + | |bgcolor = "#DCE6F1"|<font color="#0000FF"><u>[http://www.tecowestinghouse.com/products/custom_engineered/DF_WR_ind_generator.html Tecowestinghouse]</u></font> | ||

| + | |bgcolor = "#DCE6F1"|TW500XX (1-2 KW) | ||

| + | |bgcolor = "#DCE6F1"|'''Rated Power:''' 1-2 kW,''' Rated Voltage:''' 460/ 575/ 690 V, '''Frequency:''' 50/ 60 Hz, '''Number of Poles:''' 4/6, Ambient Temp.(°C): -40 to 50; '''Speed Range (% of Synch. Speed):''' 68 to 134%, '''Power Factor(Leading): -'''0.90 to <nowiki>+</nowiki>0.90, '''Insulation Class: '''H/F, '''Efficiency:''' <nowiki>></nowiki>= 96% | ||

| + | |- valign="top" | ||

| + | |align = "center"|14 | ||

| + | |<font color="#0000FF"><u>[http://www.tecowestinghouse.com/products/custom_engineered/DF_WR_ind_generator.html Tecowestinghouse]</u></font> | ||

| + | |TW560XX (2-3 KW) | ||

| + | |'''Rated Power: '''2-3kW, '''Rated Voltage: '''460/ 575/ 690 V, '''Frequency: '''50/ 60 Hz, '''Number of Poles: '''4/6, '''Ambient Temp(°C): ''' -40 to 50, '''Speed Range(% of Synch. Speed)''':''' '''68 to 134%, '''Power Factor(Leading):''' -0.90 to <nowiki>+</nowiki>0.90, '''Insulation Class: '''H/F, '''Efficiency:''' <nowiki>></nowiki>= 96%. | ||

| + | |- valign="top" | ||

| + | |align = "center" bgcolor = "#DCE6F1"|15 | ||

| + | |bgcolor = "#DCE6F1"|<font color="#0000FF"><u>[http://www.acciona-na.com/About-Us/Our-Projects/U-S-/West-Branch-Wind-Turbine-Generator-Assembly-Plant.aspx Acciona]</u></font> | ||

| + | |bgcolor = "#DCE6F1"|AW1500 | ||

| + | |bgcolor = "#DCE6F1"|'''Rated Power:''' 1.5MW, '''Rated Voltage: '''690 V, '''Frequency: '''50 Hz, '''Number of Poles: '''4, '''Rotational Speed: '''900:1,900 rpm(rated 1,680 rpm) (50Hz), '''Rated Stator Current: '''1,500 A @ 690 V, '''Protection Class: '''IP54, '''Power Factor(standard): '''0.98 CAP - 0.96 IND at partial loads and 1 at nominal power, '''Power factor(optional):''' 0.95 CAP - 0.95 IND throughout the power range | ||

| + | |- valign="top" | ||

| + | |align = "center"|16 | ||

| + | |<font color="#0000FF"><u>[http://www.acciona-na.com/About-Us/Our-Projects/U-S-/West-Branch-Wind-Turbine-Generator-Assembly-Plant.aspx Acciona]</u></font> | ||

| + | |AW3000 | ||

| + | |'''Rated Power:''' 3.0MW, '''Rated Voltage: ''' 690 V, '''Frequency: '''50 Hz, '''Number of Poles: '''4, '''Rotational Speed: '''900:1,900 rpm(rated 1,680 rpm) (50Hz), '''Rated Stator Current: '''1,500 A @ 690 V, '''Protection Class: '''IP54, '''Power Factor(standard): '''0.98 CAP - 0.96 IND at partial loads and 1 at nominal power, '''Power Factor (optional):''' 0.95 CAP - 0.95 IND throughout the power range | ||

| + | |- valign="top" | ||

| + | |align = "center" bgcolor = "#DCE6F1"|17 | ||

| + | |bgcolor = "#DCE6F1"|<font color="#0000FF"><u>[http://gepower.com/businesses/ge_wind_energy/en/index.htm General Electric]</u></font> | ||

| + | |bgcolor = "#DCE6F1"|GE 1.5/2.5MW | ||

| + | |bgcolor = "#DCE6F1"|'''Rated Power:''' 1.5/2.5 MW, '''Frequency(Hz): '''50/60 | ||

|- | |- | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

|} | |} | ||

| − | == | + | = IP Search & Analysis = |

| − | + | == Doubly-fed Induction Generator: Search Strategy == | |

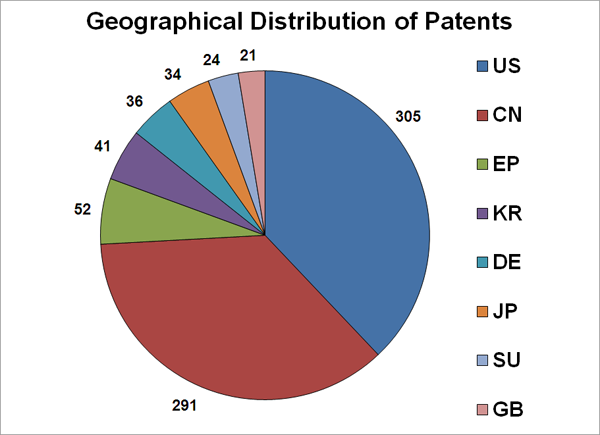

| − | + | The present study on the IP activity in the area of horizontal axis wind turbines with focus on '''''Doubly-fed Induction Generator (DFIG)''''' is based on a search conducted on Thomson Innovation. | |

| − | + | ===Control Patents=== | |

| − | === | + | |

{|border="2" cellspacing="0" cellpadding="4" width="100%" | {|border="2" cellspacing="0" cellpadding="4" width="100%" | ||

| − | |align = "center" bgcolor = "# | + | |align = "center" bgcolor = "#4F81BD" width="38"|<font color="#FFFFFF">'''S. No.'''</font> |

| − | |align = "center" bgcolor = "# | + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''Patent/Publication No.'''</font> |

| − | |- | + | |align = "center" bgcolor = "#4F81BD" width="15%"|<font color="#FFFFFF">'''Publication Date<br>'''(mm/dd/yyyy)</font> |

| − | |align = "center"| | + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''Assignee/Applicant'''</font> |

| − | | | + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''Title'''</font> |

| − | |- | + | |- valign="top" |

| − | |align = "center"| | + | |align = "center" bgcolor = "#DCE6F1"|1 |

| − | | | + | |align = "center" bgcolor = "#DCE6F1"|<font color="#0000FF"><u>[http://patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PALL&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.htm&r=1&f=G&l=50&s1=6278211.PN.&OS=PN/6278211&RS=PN/6278211 US6278211]</u></font> |

| − | |- | + | |align = "center" bgcolor = "#DCE6F1"|08/02/01 |

| − | |align = "center"| | + | |bgcolor = "#DCE6F1"|Sweo Edwin |

| − | | | + | |bgcolor = "#DCE6F1"|Brush-less doubly-fed induction machines employing dual cage rotors |

| − | |- | + | |- valign="top" |

| − | |align = "center"| | + | |align = "center"|2 |

| − | | | + | |align = "center"|<font color="#0000FF"><u>[http://patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PALL&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.htm&r=1&f=G&l=50&s1=6954004.PN.&OS=PN/6954004&RS=PN/6954004 US6954004]</u></font> |

| − | |- | + | |align = "center"|10/11/05 |

| − | |align = "center"| | + | |Spellman High Voltage Electron |

| − | | | + | |Doubly fed induction machine |

| + | |- valign="top" | ||

| + | |align = "center" bgcolor = "#DCE6F1"|3 | ||

| + | |align = "center" bgcolor = "#DCE6F1"|<font color="#0000FF"><u>[http://patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PALL&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.htm&r=1&f=G&l=50&s1=7411309.PN.&OS=PN/7411309&RS=PN/7411309 US7411309]</u></font> | ||

| + | |align = "center" bgcolor = "#DCE6F1"|08/12/08 | ||

| + | |bgcolor = "#DCE6F1"|Xantrex Technology | ||

| + | |bgcolor = "#DCE6F1"|Control system for doubly fed induction generator | ||

| + | |- valign="top" | ||

| + | |align = "center"|4 | ||

| + | |align = "center"|<font color="#0000FF"><u>[http://patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PALL&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.htm&r=1&f=G&l=50&s1=7485980.PN.&OS=PN/7485980&RS=PN/7485980 US7485980]</u></font> | ||

| + | |align = "center"|02/03/09 | ||

| + | |Hitachi | ||

| + | |Power converter for doubly-fed power generator system | ||

| + | |- valign="top" | ||

| + | |align = "center" bgcolor = "#DCE6F1"|5 | ||

| + | |align = "center" bgcolor = "#DCE6F1"|<font color="#0000FF"><u>[http://patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PALL&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.htm&r=1&f=G&l=50&s1=7800243.PN.&OS=PN/7800243&RS=PN/7800243 US7800243]</u></font> | ||

| + | |align = "center" bgcolor = "#DCE6F1"|09/21/10 | ||

| + | |bgcolor = "#DCE6F1"|Vestas Wind Systems | ||

| + | |bgcolor = "#DCE6F1"|Variable speed wind turbine with doubly-fed induction generator compensated for varying rotor speed | ||

| + | |- valign="top" | ||

| + | |align = "center"|6 | ||

| + | |align = "center"|<font color="#0000FF"><u>[http://patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PALL&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.htm&r=1&f=G&l=50&s1=7830127.PN.&OS=PN/7830127&RS=PN/7830127 US7830127]</u></font> | ||

| + | |align = "center"|11/09/10 | ||

| + | |Wind to Power System | ||

| + | |Doubly-controlled asynchronous generator | ||

|- | |- | ||

|} | |} | ||

| − | === | + | ===Patent Classes=== |

{|border="2" cellspacing="0" cellpadding="4" width="100%" | {|border="2" cellspacing="0" cellpadding="4" width="100%" | ||

| − | |align = "center" bgcolor = "# | + | |align = "center" bgcolor = "#4F81BD" width="38"|<font color="#FFFFFF">'''S. No.'''</font> |

| − | |align = "center" bgcolor = "# | + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''Class No.'''</font> |

| − | |- | + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''Class Type'''</font> |

| − | |align = "center"|290/044 | + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''Definition'''</font> |

| − | | | + | |-valign="top" |

| − | |- | + | |align = "center" bgcolor = "#DCE6F1"|1 |

| − | |align = "center"|290/055 | + | |bgcolor = "#DCE6F1"|<font color="#0000FF"><u>[http://www.wipo.int/ipcpub/#refresh=page¬ion=scheme&version=20110101&symbol=F03D0009000000 F03D9/00 ]</u></font> |

| − | | | + | |bgcolor = "#DCE6F1"|IPC |

| − | |- | + | |bgcolor = "#DCE6F1"|Machines or engines for liquids; wind, spring, or weight motors; producing mechanical power or a reactive propulsive thrust, not otherwise provided for / Wind motors / '''Adaptations of wind motors for special use; Combination of wind motors with apparatus driven thereby (aspects predominantly concerning driven apparatus) ''' |

| − | |align = "center"|318/727 | + | |-valign="top" |

| − | | | + | |align = "center"|2 |

| − | |- | + | |<font color="#0000FF"><u>[http://v3.espacenet.com/eclasrch?classification=ecla&locale=en_EP&ECLA=f03d9/00c F03D9/00C ]</u></font> |

| − | |align = "center"|322/047 | + | |ECLA |

| − | | | + | |Machines or engines for liquids; wind, spring, or weight motors; producing mechanical power or a reactive propulsive thrust, not otherwise provided for / Wind motors / Adaptations of wind motors for special use; Combination of wind motors with apparatus driven thereby (aspects predominantly concerning driven apparatus) /''' The apparatus being an electrical generator ''' |

| + | |-valign="top" | ||

| + | |align = "center" bgcolor = "#DCE6F1"|3 | ||

| + | |bgcolor = "#DCE6F1"|<font color="#0000FF"><u>[http://www.wipo.int/ipcpub/#&refresh=page¬ion=scheme&version=20110101&symbol=H02J0003380000 H02J3/38 ]</u></font> | ||

| + | |bgcolor = "#DCE6F1"|IPC | ||

| + | |bgcolor = "#DCE6F1"|Generation, conversion, or distribution of electric power / Circuit arrangements or systems for supplying or distributing electric power; systems for storing electric energy / Circuit arrangements for ac mains or ac distribution networks / '''Arrangements for parallely feeding a single network by two or more generators, converters or transformers ''' | ||

| + | |-valign="top" | ||

| + | |align = "center"|4 | ||

| + | |<font color="#0000FF"><u>[http://www.wipo.int/ipcpub/#refresh=page¬ion=scheme&version=20110101&symbol=H02K0017420000 H02K17/42 ] | ||

| + | </u></font> | ||

| + | |IPC | ||

| + | |Generation, conversion, or distribution of electric power / Dynamo-electric machines / Asynchronous induction motors; Asynchronous induction generators / '''Asynchronous induction generators ''' | ||

| + | |-valign="top" | ||

| + | |align = "center" bgcolor = "#DCE6F1"|5 | ||

| + | |bgcolor = "#DCE6F1"|<font color="#0000FF"><u>[http://www.wipo.int/ipcpub/#refresh=page¬ion=scheme&version=20110101&symbol=H02P0009000000 H02P9/00 ]</u></font> | ||

| + | |bgcolor = "#DCE6F1"|IPC | ||

| + | |bgcolor = "#DCE6F1"|Generation, conversion, or distribution of electric power / Control or regulation of electric motors, generators, or dynamo-electric converters; controlling transformers, reactors or choke coils /''' Arrangements for controlling electric generators for the purpose of obtaining a desired output ''' | ||

| + | |-valign="top" | ||

| + | |align = "center"|6 | ||

| + | |<font color="#0000FF"><u>[http://www.uspto.gov/web/patents/classification/uspc290/sched290.htm#C290S044000 290/044]</u></font> | ||

| + | |USPC | ||

| + | |Prime-mover dynamo plants / electric control / Fluid-current motors / '''Wind ''' | ||

| + | |-valign="top" | ||

| + | |align = "center" bgcolor = "#DCE6F1"|7 | ||

| + | |bgcolor = "#DCE6F1"|<font color="#0000FF"><u>[http://www.uspto.gov/web/patents/classification/uspc290/sched290.htm#C290S055000 290/055]</u></font> | ||

| + | |bgcolor = "#DCE6F1"|USPC | ||

| + | |bgcolor = "#DCE6F1"|Prime-mover dynamo plants / Fluid-current motors / '''Wind''' | ||

| + | |-valign="top" | ||

| + | |align = "center"|8 | ||

| + | |<font color="#0000FF"><u>[http://www.uspto.gov/web/patents/classification/uspc318/sched318.htm#C318S727000 318/727]</u></font> | ||

| + | |USPC | ||

| + | |Electricity: motive power systems / '''Induction motor systems ''' | ||

| + | |-valign="top" | ||

| + | |align = "center" bgcolor = "#DCE6F1"|9 | ||

| + | |bgcolor = "#DCE6F1"|<font color="#0000FF"><u>[http://www.uspto.gov/web/patents/classification/uspc322/sched322.htm#C322S047000 322/047]</u></font> | ||

| + | |bgcolor = "#DCE6F1"|USPC | ||

| + | |bgcolor = "#DCE6F1"|Electricity: single generator systems / Generator control / '''Induction generator ''' | ||

|- | |- | ||

|} | |} | ||

| − | |||

| − | |||

===Concept Table=== | ===Concept Table=== | ||

| − | {|border="2" cellspacing="0" cellpadding="4" width=" | + | {|border="2" cellspacing="0" cellpadding="4" width="100%" |

| − | |align = "center" bgcolor = "# | + | |align = "center" bgcolor = "#4F81BD" rowspan = "2" width="38"|<font color="#FFFFFF">'''S. No.'''</font> |

| − | |align = "center" bgcolor = "# | + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''Concept 1'''</font> |

| − | |align = "center" bgcolor = "# | + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''Concept 2'''</font> |

| − | |align = "center" bgcolor = "# | + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''Concept 3'''</font> |

|- | |- | ||

| − | |align = "center"|1 | + | |align = "center" bgcolor = "#95B3D7"|'''Doubly Fed''' |

| − | | | + | |align = "center" bgcolor = "#95B3D7"|'''Induction''' |

| − | | | + | |align = "center" bgcolor = "#95B3D7"|'''Generator''' |

| − | | | + | |- |

| + | |align = "center" bgcolor = "#DCE6F1"|1 | ||

| + | |bgcolor = "#DCE6F1"|doubly fed | ||

| + | |bgcolor = "#DCE6F1"|induction | ||

| + | |bgcolor = "#DCE6F1"|generator | ||

|- | |- | ||

|align = "center"|2 | |align = "center"|2 | ||

| − | | | + | |double output |

| − | | | + | |asynchronous |

| − | | | + | |machines |

|- | |- | ||

| − | |align = "center"|3 | + | |align = "center" bgcolor = "#DCE6F1"|3 |

| − | | | + | |bgcolor = "#DCE6F1"|dual fed |

| − | | | + | |bgcolor = "#DCE6F1"| |

| − | | | + | |bgcolor = "#DCE6F1"|systems |

|- | |- | ||

|align = "center"|4 | |align = "center"|4 | ||

| − | | | + | |dual feed |

| − | | | + | | |

| − | | | + | | |

|- | |- | ||

| − | |align = "center"|5 | + | |align = "center" bgcolor = "#DCE6F1"|5 |

| − | | | + | |bgcolor = "#DCE6F1"|dual output |

| − | | | + | |bgcolor = "#DCE6F1"| |

| − | | | + | |bgcolor = "#DCE6F1"| |

|- | |- | ||

|} | |} | ||

| − | ===Search | + | ===Thomson Innovation Search=== |

| − | + | '''Database:''' Thomson Innovation<br> | |

| − | + | '''Patent coverage:''' US EP WO JP DE GB FR CN KR DWPI<br> | |

| − | + | '''Time line:''' 01/01/1836 to 07/03/2011 | |

| − | + | ||

{|border="2" cellspacing="0" cellpadding="4" width="100%" | {|border="2" cellspacing="0" cellpadding="4" width="100%" | ||

| − | |align = "center" bgcolor = "# | + | |align = "center" bgcolor = "#4F81BD" width="38"|<font color="#FFFFFF">'''S. No.'''</font> |

| − | |align = "center" bgcolor = "# | + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''Concept'''</font> |

| − | |align = "center" bgcolor = "# | + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''Scope'''</font> |

| − | |align = "center" bgcolor = "# | + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''Search String'''</font> |

| − | + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''No. of Hits'''</font> | |

| − | |align = "center"| | + | |-valign="top" |

| − | |align = "center"| | + | |align = "center" bgcolor = "#DCE6F1"|1 |

| − | |Doubly fed | + | |bgcolor = "#DCE6F1"|Doubly-fed Induction Generator: Keywords(broad) |

| − | | | + | |bgcolor = "#DCE6F1"|Claims, Title, and Abstract |

| − | |- | + | |bgcolor = "#DCE6F1"|(((((doubl<nowiki>*</nowiki>3 OR dual<nowiki>*</nowiki>3 OR two) ADJ3 (power<nowiki>*</nowiki>2 OR output<nowiki>*</nowiki>4 OR control<nowiki>*</nowiki>4 OR fed OR feed<nowiki>*</nowiki>3)) NEAR5 (induction OR asynchronous)) NEAR5 (generat<nowiki>*</nowiki>3 OR machine<nowiki>*</nowiki>1 OR dynamo<nowiki>*</nowiki>1)) OR dfig or doig) |

| + | |align = "right" bgcolor = "#DCE6F1"|873 | ||

| + | |-valign="top" | ||

|align = "center"|2 | |align = "center"|2 | ||

| − | | | + | |Doubly-fed Induction Generator: Keywords(broad) |

| − | + | |Full Spec. | |

| − | |( | + | |(((((doubl<nowiki>*</nowiki>3 OR dual<nowiki>*</nowiki>3 OR two) ADJ3 (power<nowiki>*</nowiki>2 OR output<nowiki>*</nowiki>1 OR control<nowiki>*</nowiki>4 OR fed OR feed<nowiki>*</nowiki>3)) NEAR5 (generat<nowiki>*</nowiki>3 OR machine<nowiki>*</nowiki>1 OR dynamo<nowiki>*</nowiki>1))) OR dfig or doig) |

| − | |- | + | |align = "center"|<nowiki>-</nowiki> |

| − | |align = "center"|3 | + | |-valign="top" |

| − | | | + | |align = "center" bgcolor = "#DCE6F1"|3 |

| − | | | + | |bgcolor = "#DCE6F1"|Induction Machine: Classes |

| − | | | + | |bgcolor = "#DCE6F1"|US, IPC, and ECLA Classes |

| − | |- | + | |bgcolor = "#DCE6F1"|((318/727 OR 322/047) OR (H02K001742)) |

| + | |align = "center" bgcolor = "#DCE6F1"|<nowiki>-</nowiki> | ||

| + | |-valign="top" | ||

|align = "center"|4 | |align = "center"|4 | ||

| − | | | + | |Generators: Classes |

| − | | | + | |US, IPC, and ECLA Classes |

| − | | | + | |((290/044 OR 290/055) OR (F03D000900C OR H02J000338 OR F03D0009<nowiki>*</nowiki> OR H02P0009<nowiki>*</nowiki>)) |

| − | |- | + | |align = "center"|<nowiki>-</nowiki> |

| − | |align = "center"|5 | + | |-valign="top" |

| − | |align = "center"| | + | |align = "center" bgcolor = "#DCE6F1"|5 |

| − | | | + | |bgcolor = "#DCE6F1"|Combined Query |

| − | | | + | |align = "center" bgcolor = "#DCE6F1"|<nowiki>-</nowiki> |

| − | |- | + | |align = "left" bgcolor = "#DCE6F1"|2 AND 3 |

| + | |align = "right" bgcolor = "#DCE6F1"|109 | ||

| + | |-valign="top" | ||

|align = "center"|6 | |align = "center"|6 | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

|Combined Query | |Combined Query | ||

| − | |1 OR 2 OR 3 OR 4 OR 5 OR 6 | + | |align = "center"|<nowiki>-</nowiki> |

| + | |align = "left"|2 AND 4 | ||

| + | |align = "right"|768 | ||

| + | |-valign="top" | ||

| + | |align = "center" bgcolor = "#DCE6F1"|7 | ||

| + | |bgcolor = "#DCE6F1"|French Keywords | ||

| + | |bgcolor = "#DCE6F1"|Claims, Title, and Abstract | ||

| + | |bgcolor = "#DCE6F1"|((((doubl<nowiki>*</nowiki>3 OR dual<nowiki>*</nowiki>3 OR two OR deux) NEAR4 (nourris OR feed<nowiki>*</nowiki>3 OR puissance OR sortie<nowiki>*</nowiki>1 OR contrôle<nowiki>*</nowiki>1)) NEAR4 (induction OR asynchron<nowiki>*</nowiki>1) NEAR4 (générateur<nowiki>*</nowiki>1 OR generator<nowiki>*</nowiki>1 OR machine<nowiki>*</nowiki>1 OR dynamo<nowiki>*</nowiki>1)) OR dfig or doig) | ||

| + | |align = "right" bgcolor = "#DCE6F1"|262 | ||

| + | |-valign="top" | ||

| + | |align = "center"|8 | ||

| + | |German Keywords | ||

| + | |Claims, Title, and Abstract | ||

| + | |(((((doppel<nowiki>*</nowiki>1 OR dual OR two OR zwei) ADJ3 (ausgang OR ausgänge OR kontroll<nowiki>*</nowiki> OR control<nowiki>*</nowiki>4 OR gesteuert OR macht OR feed<nowiki>*</nowiki>1 OR gefüttert OR gespeiste<nowiki>*</nowiki>1)) OR (doppeltgefüttert OR doppeltgespeiste<nowiki>*</nowiki>1)) NEAR4 (((induktion OR asynchronen) NEAR4 (generator<nowiki>*</nowiki>2 OR maschine<nowiki>*</nowiki>1 OR dynamo<nowiki>*</nowiki>1)) OR (induktion?maschinen OR induktion?generatoren OR asynchronmaschine OR asynchrongenerator))) OR dfig) | ||

| + | |align = "right"|306 | ||

| + | |-valign="top" | ||

| + | |align = "center" bgcolor = "#DCE6F1"|9 | ||

| + | |bgcolor = "#DCE6F1"|Doubly-fed Induction Generator: Keywords(narrow) | ||

| + | |bgcolor = "#DCE6F1"|Full Spec. | ||

| + | |bgcolor = "#DCE6F1"|(((((((doubl<nowiki>*</nowiki>3 OR dual<nowiki>*</nowiki>3) ADJ3 (power<nowiki>*</nowiki>2 OR output<nowiki>*</nowiki>4 OR control<nowiki>*</nowiki>4 OR fed OR feed<nowiki>*</nowiki>3))) NEAR5 (generat<nowiki>*</nowiki>3 OR machine<nowiki>*</nowiki>1 OR dynamo<nowiki>*</nowiki>1))) SAME wind) OR (dfig SAME wind)) | ||

| + | |align = "right" bgcolor = "#DCE6F1"|1375 | ||

| + | |-valign="top" | ||

| + | |align = "center"|10 | ||

| + | | Top Assignees | ||

| + | |align = "center"|<nowiki>-</nowiki> | ||

| + | |(vestas* OR (gen* ADJ2 electric*) OR ge OR hitachi OR woodward OR repower OR areva OR gamesa OR ingeteam OR nordex OR siemens OR (abb ADJ2 research) OR (american ADJ2 superconductor*) OR (korea ADJ2 electro*) OR (univ* NEAR3 navarra) OR (wind OR technolog*) OR (wind ADJ2 to ADJ2 power)) | ||

| + | |align = "center"|- | ||

| + | |-valign="top" | ||

| + | |align = "center" bgcolor = "#DCE6F1"|11 | ||

| + | |bgcolor = "#DCE6F1"|Combined Query | ||

| + | |align = "center" bgcolor = "#DCE6F1"|<nowiki>-</nowiki> | ||

| + | |bgcolor = "#DCE6F1"|2 AND 10 | ||

| + | |align = "right" bgcolor = "#DCE6F1"|690 | ||

| + | |-valign="top" | ||

| + | |align = "center"|12 | ||

| + | |Top Inventors | ||

| + | |align = "center"|<nowiki>-</nowiki> | ||

| + | |((Andersen NEAR2 Brian) OR (Engelhardt NEAR2 Stephan) OR (Ichinose NEAR2 Masaya) OR (Jorgensen NEAR2 Allan NEAR2 Holm) OR ((Scholte ADJ2 Wassink) NEAR2 Hartmut) OR (OOHARA NEAR2 Shinya) OR (Rivas NEAR2 Gregorio) OR (Erdman NEAR2 William) OR (Feddersen NEAR2 Lorenz) OR (Fortmann NEAR2 Jens) OR (Garcia NEAR2 Jorge NEAR2 Martinez) OR (Gertmar NEAR2 Lars) OR (KROGH NEAR2 Lars) OR (LETAS NEAR2 Heinz NEAR2 Hermann) OR (Lopez NEAR2 Taberna NEAR2 Jesus) OR (Nielsen NEAR2 John) OR (STOEV NEAR2 Alexander) OR (W?ng NEAR2 Haiqing) OR (Yuan NEAR2 Xiaoming)) | ||

| + | |align = "center"|- | ||

| + | |-valign="top" | ||

| + | |align = "center" bgcolor = "#DCE6F1"|13 | ||

| + | |bgcolor = "#DCE6F1" |Combined Query | ||

| + | |align = "center" bgcolor = "#DCE6F1"|<nowiki>-</nowiki> | ||

| + | |bgcolor = "#DCE6F1"|((3 OR 4) AND 10) | ||

| + | |align = "right" bgcolor = "#DCE6F1"|899 | ||

| + | |-valign="top" | ||

| + | |align = "center"|14 | ||

| + | |Final Query | ||

| + | |align = "center"|<nowiki>-</nowiki> | ||

| + | |1 OR 5 OR 6 OR 7 OR 8 OR 9 OR 11 OR 13 | ||

| + | |'''2466(1060 INPADOC Families)''' | ||

|- | |- | ||

|} | |} | ||

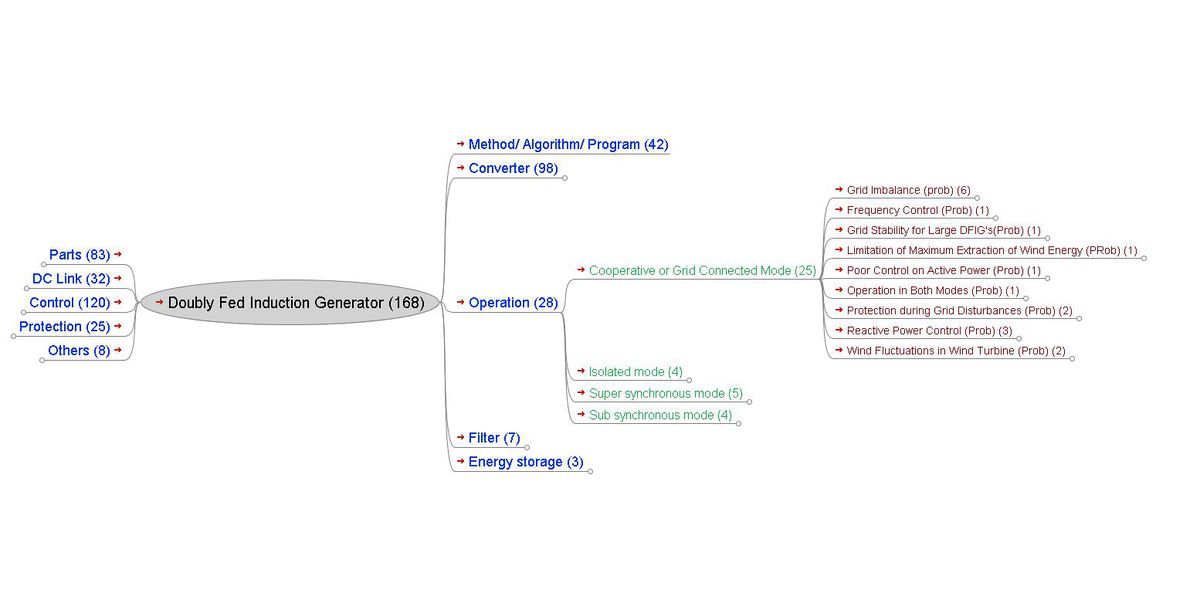

==Taxonomy== | ==Taxonomy== | ||

| − | <mm>[[ | + | *''Use the mouse(click and drag/scroll up or down/click on nodes) to explore nodes in the detailed taxonomy'' |

| + | *''Click on the red arrow adjacent to the node name to view the content for that particular node in the dashboard'' | ||

| + | {|border="2" cellspacing="0" cellpadding="4" width="100%" | ||

| + | |<mm>[[Doubly_fed_Induction_Generator.mm|Interactive Mind-map|center|flash|Doubly-fed Induction Generator|600pt]]</mm> | ||

| + | |} | ||

==Sample Analysis== | ==Sample Analysis== | ||

| − | A sample of 139 patents from the search | + | A sample of 139 patents from the search is analyzed based on the taxonomy. |

Provided a link below for sample spread sheet analysis for doubly-fed induction generators.<br> | Provided a link below for sample spread sheet analysis for doubly-fed induction generators.<br> | ||

===Patent Analysis=== | ===Patent Analysis=== | ||

| − | {| border="2" cellspacing="0" cellpadding=" | + | {|border="2" cellspacing="0" cellpadding="4" width="100%" |

| − | | rowspan="2" | + | |align = "center" bgcolor = "#4F81BD" rowspan = "2" width="38"|<font color="#FFFFFF">'''S.No.'''</font> |

| − | | | + | |align = "center" bgcolor = "#4F81BD" rowspan = "2" |<font color="#FFFFFF">'''Patent/Publication No.'''</font> |

| − | | rowspan="2" | + | |align = "center" bgcolor = "#4F81BD" rowspan = "2" width="105"|<font color="#FFFFFF">'''Publication Date<br>'''(mm/dd/yyyy)</font> |

| − | | | + | |align = "center" bgcolor = "#4F81BD" rowspan = "2"|<font color="#FFFFFF">'''Assignee/Applicant'''</font> |

| − | | | + | |align = "center" bgcolor = "#4F81BD" rowspan = "2"|<font color="#FFFFFF">'''Title'''</font> |

| − | | | + | |align = "center" bgcolor = "#4F81BD" colspan = "2"|<font color="#FFFFFF">'''Dolcera Analysis'''</font> |

| − | + | ||

|- | |- | ||

| − | | | + | |align = "center" bgcolor = "#95B3D7"|'''Problem''' |

| − | | | + | |align = "center" bgcolor = "#95B3D7"|'''Solution''' |

| − | + | |-valign="top" | |

| + | |align = "center" bgcolor = "#DCE6F1"|1 | ||

| + | |bgcolor = "#DCE6F1"|<font color="#0000FF"><u>[http://appft1.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PG01&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.html&r=1&f=G&l=50&s1=%2220100117605%22.PGNR.&OS=DN/20100117605&RS=DN/20100117605 US20100117605]</u></font> | ||

| + | |align = "center" bgcolor = "#DCE6F1"|05/13/10 | ||

| + | |bgcolor = "#DCE6F1"|Woodward | ||

| + | |bgcolor = "#DCE6F1"|Method of and apparatus for operating a double-fed asynchronous machine in the event of transient mains voltage changes | ||

| + | |bgcolor = "#DCE6F1"|The short-circuit-like currents in the case of transient mains voltage changes lead to a corresponding air gap torque which loads the drive train and transmission lines can damages or reduces the drive train and power system equipments. | ||

| + | |bgcolor = "#DCE6F1"|The method presents that the stator connecting with the network and the rotor with a converter. The converter is formed to set a reference value of electrical amplitude in the rotor, by which a reference value of the electrical amplitude is set in the rotor after attaining a transient mains voltage change, such that the rotor flux approaches the stator flux. | ||

| + | |-valign="top" | ||

| + | |align = "center"|2 | ||

| + | |<font color="#0000FF"><u>[http://appft1.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PG01&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.html&r=1&f=G&l=50&s1=%2220100045040%22.PGNR.&OS=DN/20100045040&RS=DN/20100045040 US20100045040]</u></font> | ||

| + | |align = "center"|02/25/10 | ||

| + | |Vestas Wind Systems | ||

| + | |Variable speed wind turbine with doubly-fed induction generator compensated for varying rotor speed | ||

| + | |The DFIG system has poor damping of oscillations within the flux dynamics due to cross coupling between active and reactive currents, which makes the system potentially unstable under certain circumstances and complicates the work of the rotor current controller. These oscillations can damage the drive train mechanisms. | ||

| + | |A compensation block is arranged, which feeds a compensation control output to the rotor of the generator. The computation unit computes the control output during operation of the turbine to compensate partly for dependencies on a rotor angular speed of locations of poles of a generator transfer function, so that the transfer function is made independent of variations in the speed during operation of the turbine which eliminates the oscillations and increases the efficiency of the wind turbine. | ||

| + | |-valign="top" | ||

| + | |align = "center" bgcolor = "#DCE6F1"|3 | ||

| + | |bgcolor = "#DCE6F1"|<font color="#0000FF"><u>[http://appft1.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PG01&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.html&r=1&f=G&l=50&s1=%2220090267572%22.PGNR.&OS=DN/20090267572&RS=DN/20090267572 US20090267572]</u></font> | ||

| + | |align = "center" bgcolor = "#DCE6F1"|10/29/09 | ||

| + | |bgcolor = "#DCE6F1"|Woodward | ||

| + | |bgcolor = "#DCE6F1"|Current limitation for a double-fed asynchronous machine | ||

| + | |bgcolor = "#DCE6F1"|Abnormal currents can damage the windings in the doubly- fed induction generator. Controlling these currents with the subordinate current controllers cannot be an efficient way to extract the maximum amount of active power. | ||

| + | |bgcolor = "#DCE6F1"|The method involves delivering or receiving of a maximum permissible reference value of an active power during an operation of a double-fed asynchronous machine, where predetermined active power and reactive power reference values are limited to a calculated maximum permissible active and reactive power reference values, and hence ensures reliable regulated effect and reactive power without affecting the power adjustment, the rotor is electrically connected to a pulse-controlled inverter by slip rings with a static frequency changer, and thus a tension with variable amplitude and frequency is imposed in the rotor. | ||

| + | |-valign="top" | ||

| + | |align = "center"|4 | ||

| + | |<font color="#0000FF"><u>[http://appft1.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PG01&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.html&r=1&f=G&l=50&s1=%2220090008944%22.PGNR.&OS=DN/20090008944&RS=DN/20090008944 US20090008944]</u></font> | ||

| + | |align = "center"|01/08/09 | ||

| + | |Universidad Publica De Navarra | ||

| + | |Method and system of control of the converter of an electricity generation facility connected to an electricity network in the presence of voltage sags in said network | ||

| + | |Double-fed asynchronous generators are very sensitive to the faults that may arise in the electricity network, such as voltage sags. During the sag conditions the current which appears in said converter may reach very high values, and may even destroy it. | ||

| + | |During the event of a voltage sag occurring, the converter imposes a new set point current which is the result of adding to the previous set point current a new term, called demagnetizing current, It is proportional to a value of free flow of a generator stator. A difference between a value of a magnetic flow in the stator of the generator and a value of a stator flow associated to a direct component of a stator voltage is estimated. A value of a preset calculated difference is multiplied by a factor for producing the demagnetizing current. | ||

| + | |-valign="top" | ||

| + | |align = "center" bgcolor = "#DCE6F1"|5 | ||

| + | |bgcolor = "#DCE6F1"|<font color="#0000FF"><u>[http://patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PALL&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.htm&r=1&f=G&l=50&s1=7355295.PN.&OS=PN/7355295&RS=PN/7355295 US7355295]</u></font> | ||

| + | |align = "center" bgcolor = "#DCE6F1"|04/08/08 | ||

| + | |bgcolor = "#DCE6F1"|Ingeteam Energy | ||

| + | |bgcolor = "#DCE6F1"|Variable speed wind turbine having an exciter machine and a power converter not connected to the grid | ||

| + | |bgcolor = "#DCE6F1"|a) The active switching of the semiconductors of the grid side converter injects undesirable high frequency harmonics to the grid.<br>b) The use of power electronic converters (4) connected to the grid (9) causes harmonic distortion of the network voltage. | ||

| + | |bgcolor = "#DCE6F1"|Providing the way that power is only delivered to the grid through the stator of the doubly fed induction generator, avoiding undesired harmonic distortion. <br>Grid Flux Orientation (GFO) is used to accurately control the power injected to the grid. An advantage of this control system is that it does not depend on machine parameters, which may vary significantly, and theoretical machine models, avoiding the use of additional adjusting loops and achieving a better power quality fed into the utility grid. | ||

| + | |-valign="top" | ||

| + | |align = "center"|6 | ||

| + | |<font color="#0000FF"><u>[http://appft1.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PG01&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.html&r=1&f=G&l=50&s1=%2220080203978%22.PGNR.&OS=DN/20080203978&RS=DN/20080203978 US20080203978]</u></font> | ||

| + | |align = "center"|08/28/08 | ||

| + | |Semikron | ||

| + | |Frequency converter for a double-fed asynchronous generator with variable power output and method for its operation | ||

| + | |Optislip circuit with a resistor is used when speed is above synchronous speed, results in heating the resistor and thus the generator leads to limitation of operation in super synchronous range which results in tower fluctuations. | ||

| + | |Providing a back-to-back converter which contains the inverter circuit has direct current (DC) inputs, DC outputs, and a rotor-rectifier connected to a rotor of a dual feed asynchronous generator. A mains inverter is connected to a power grid, and an intermediate circuit connects one of the DC inputs with the DC outputs. The intermediate circuit has a semiconductor switch between the DC outputs, an intermediate circuit condenser between the DC inputs, and a diode provided between the semiconductor switch and the condenser. Thus the system is allowed for any speed of wind and reduces the tower fluctuations. | ||

| + | |-valign="top" | ||

| + | |align = "center" bgcolor = "#DCE6F1"|7 | ||

| + | |bgcolor = "#DCE6F1"|<font color="#0000FF"><u>[http://appft1.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PG01&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.html&r=1&f=G&l=50&s1=%2220070210651%22.PGNR.&OS=DN/20070210651&RS=DN/20070210651 US20070210651]</u></font> | ||

| + | |align = "center" bgcolor = "#DCE6F1"|09/13/07 | ||

| + | |bgcolor = "#DCE6F1"|Hitachi | ||

| + | |bgcolor = "#DCE6F1"|Power converter for doubly-fed power generator system | ||

| + | |bgcolor = "#DCE6F1"|During the ground faults, excess currents is induced in the secondary windings and flows into power converter connected to secondary side and may damage the power converter. Conventional methods of increasing the capacity of the power converter increases system cost, degrade the system and takes time to activate the system to supply power again. | ||

| + | |bgcolor = "#DCE6F1"|The generator provided with a excitation power converter connected to secondary windings of a doubly-fed generator via impedance e.g. reactor, and a diode rectifier connected in parallel to the second windings of the doubly-fed generator via another impedance. A direct current link of the rectifier is connected in parallel to a DC link of the converter. A controller outputs an on-command to a power semiconductor switching element of the converter if a value of current flowing in the power semiconductor switching element is a predetermined value or larger. | ||

| + | |-valign="top" | ||

| + | |align = "center"|8 | ||

| + | |<font color="#0000FF"><u>[http://appft1.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PG01&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.html&r=1&f=G&l=50&s1=%2220070132248%22.PGNR.&OS=DN/20070132248&RS=DN/20070132248 US20070132248]</u></font> | ||

| + | |align = "center"|06/14/07 | ||

| + | |General Electric | ||

| + | |System and method of operating double fed induction generators | ||

| + | |Wind turbines with double fed induction generators are sensitive to grid faults. Conventional methods are not effective to reduce the shaft stress during grid faults and slow response and using dynamic voltage restorer (DVR) is cost expensive. | ||

| + | |The protection system has a controlled impedance device. Impedance device has bidirectional semiconductors such triac, assembly of thyristors or anti-parallel thyristors. Each of the controlled impedance devices is coupled between a respective phase of a stator winding of a double fed induction generator and a respective phase of a grid side converter. The protection system also includes a controller configured for coupling and decoupling impedance in one or more of the controlled impedance devices in response to changes in utility grid voltage and a utility grid current. High impedance is offered to the grid during network faults to isolate the dual fed wind turbine generator. | ||

| + | |-valign="top" | ||

| + | |align = "center" bgcolor = "#DCE6F1"|9 | ||

| + | |bgcolor = "#DCE6F1"|<font color="#0000FF"><u>[http://appft1.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PG01&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.html&r=1&f=G&l=50&s1=%2220060192390%22.PGNR.&OS=DN/20060192390&RS=DN/20060192390 US20060192390]</u></font> | ||

| + | |align = "center" bgcolor = "#DCE6F1"|08/31/06 | ||

| + | |bgcolor = "#DCE6F1"|Gamesa Innovation | ||

| + | |bgcolor = "#DCE6F1"|Control and protection of a doubly-fed induction generator system | ||

| + | |bgcolor = "#DCE6F1"|A short-circuit in the grid causes the generator to feed high stator-currents into the short-circuit and the rotor-currents increase very rapidly which cause damage to the power-electronic components of the converter connecting the rotor windings with the rotor-inverter. | ||

| + | |bgcolor = "#DCE6F1"|The converter is provided with a clamping unit which is triggered from a non-operation state to an operation state, during detection of over-current in the rotor windings. The clamping unit comprises passive voltage-dependent resistor element for providing a clamping voltage over the rotor windings when the clamping unit is triggered. | ||

| + | |-valign="top" | ||

| + | |align = "center"|10 | ||

| + | |<font color="#0000FF"><u>[http://appft1.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PG01&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.html&r=1&f=G&l=50&s1=%2220050189896%22.PGNR.&OS=DN/20050189896&RS=DN/20050189896 US20050189896]</u></font> | ||

| + | |align = "center"|09/01/05 | ||

| + | |ABB Research | ||

| + | |Method for controlling doubly-fed machine | ||

| + | |Controlling the double fed machines on the basis of inverter control to implement the targets set for the machine, this model is extremely complicated and includes numerous parameters that are often to be determined. | ||

| + | |A method is provided to use a standard scalar-controlled frequency converter for machine control. A frequency reference for the inverter with a control circuit, and reactive power reference are set for the machine. A rotor current compensation reference is set based on reactive power reference and reactive power. A scalar-controlled inverter is controlled for producing voltage for the rotor of the machine, based on the set frequency reference and rotor current compensation reference. | ||

|- | |- | ||

| − | | | + | |} |

| − | + | Click '''[[Media:Doublyfed_induction_generator1.xls| here]]''' to view the detailed analysis sheet for doubly-fed induction generators patent analysis. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| + | ===Article Analysis=== | ||

| + | {|border="2" cellspacing="0" cellpadding="4" width="100%" | ||

| + | |align = "center" bgcolor = "#4F81BD" width="38"|<font color="#FFFFFF">'''S.No.'''</font> | ||

| + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''Title'''</font> | ||

| + | |align = "center" bgcolor = "#4F81BD" width="105"|<font color="#FFFFFF">'''Publication Date<br>'''(mm/dd/yyyy)</font> | ||

| + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''Journal/Conference'''</font> | ||

| + | |align = "center" bgcolor = "#4F81BD"|<font color="#FFFFFF">'''Dolcera Summary'''</font> | ||

| + | |-valign="top" | ||

| + | |align = "center" bgcolor = "#DCE6F1"|1 | ||

| + | |bgcolor = "#DCE6F1"|<font color="#0000FF"><u>[http://ieeexplore.ieee.org/search/freesrchabstract.jsp?tp=&arnumber=1709031&queryText=Study+on+the+Control+of+DFIG+and+Its+Responses+to+Grid+Disturbances&openedRefinements=*&searchField=Search+All Study on the Control of DFIG and its Responses to Grid Disturbances ]</u></font> | ||

| + | |align = "center" bgcolor = "#DCE6F1"|01/01/06 | ||

| + | |bgcolor = "#DCE6F1"|Power Engineering Society General Meeting, 2006. IEEE | ||

| + | |bgcolor = "#DCE6F1"|Presented dynamic model of the DFIG, including mechanical model, generator model, and PWM voltage source converters. Vector control strategies adapted for both the RSC and GSC to control speed and reactive power independently. Control designing methods, such as pole-placement method and the internal model control are used. MATLAB/Simulink is used for simulation. | ||

| + | |-valign="top" | ||

| + | |align = "center"|2 | ||

| + | |<font color="#0000FF"><u>[http://ieeexplore.ieee.org/search/freesrchabstract.jsp?tp=&arnumber=1649950&queryText=Application+of+Matrix+Converter+for+Variable+Speed+Wind+Turbine+Driving+an+Doubly+Fed+Induction+Generator&openedRefinements=*&searchField=Search+All Application of Matrix Converter for Variable Speed Wind Turbine Driving an Doubly Fed Induction Generator ]</u></font> | ||

| + | |align = "center"|05/23/06 | ||

| + | |Power Electronics, Electrical Drives, Automation and Motion, 2006. SPEEDAM 2006. | ||

| + | |A matrix converter is replaced with back to back converter in a variable speed wind turbine using doubly fed induction generator. Stable operation is achieved by stator flux oriented control technique and the system operated in both sub and super synchronous modes, achieved good results. | ||

| + | |-valign="top" | ||

| + | |align = "center" bgcolor = "#DCE6F1"|3 | ||