Difference between revisions of "Tight Gas Fracturing Technology and Patent Report"

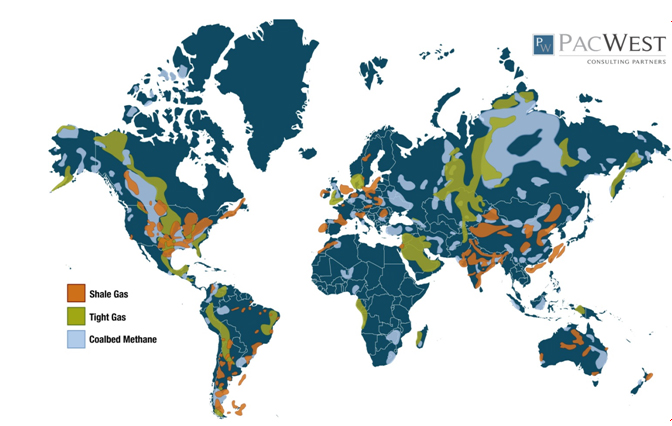

(→Map of unconventional reserves (Shale,Tight,Coalbed methane) in the world) |

(→IP Activity) |

||

| (75 intermediate revisions by the same user not shown) | |||

| Line 23: | Line 23: | ||

[[Image:Worldwide conventional oil depletion scenario.jpg|left|thumb|400px|[http://greatchange.org/ov-bentley,global_depletion.pdf]]] | [[Image:Worldwide conventional oil depletion scenario.jpg|left|thumb|400px|[http://greatchange.org/ov-bentley,global_depletion.pdf]]] | ||

| − | [[Image:Worldwide conventional gas depletion scenario.jpg|centre|thumb|400px|[http://greatchange.org/ov-bentley,global_depletion.pdf]]] | + | [[Image:Worldwide conventional gas depletion-scenario.jpg|centre|thumb|400px|[http://greatchange.org/ov-bentley,global_depletion.pdf]]] |

| Line 35: | Line 35: | ||

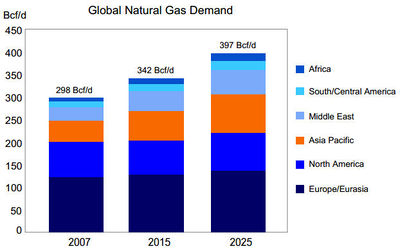

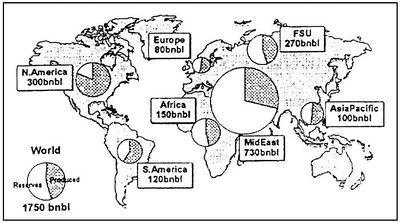

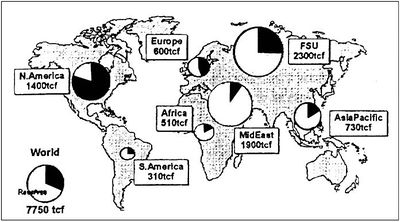

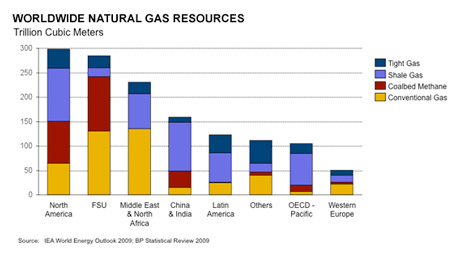

[http://www.sbc.slb.com/Our_Work/Energy_Expertise/CO2_Emissions_Clean_Energy.aspx '''Worldwide Natural gas resources] | [http://www.sbc.slb.com/Our_Work/Energy_Expertise/CO2_Emissions_Clean_Energy.aspx '''Worldwide Natural gas resources] | ||

| − | [[Image:Worldwide distribution of Natural Gas Resources.jpg|left|thumb| | + | [[Image:Worldwide distribution of Natural Gas Resources.jpg|left|thumb|600px|[http://www.sbc.slb.com/Our_Work/Energy_Expertise/CO2_Emissions_Clean_Energy.aspx Fig. 4 Worldwide distribution of Natural Gas Resources]]] |

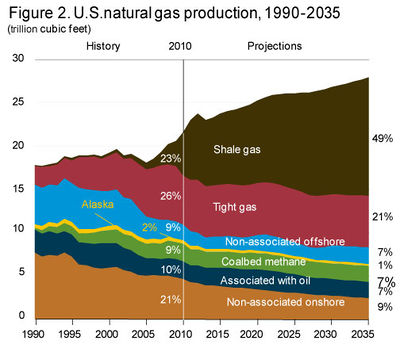

[[Image:U.S Natural Gas Production, prediction from 1990 to 2035 year.jpg|centre|thumb|400px|[http://www.sbc.slb.com/Our_Work/Energy_Expertise/CO2_Emissions_Clean_Energy.aspx Fig.5 U.S Natural Gas Production, prediction from 1990 to 2035 year]]] | [[Image:U.S Natural Gas Production, prediction from 1990 to 2035 year.jpg|centre|thumb|400px|[http://www.sbc.slb.com/Our_Work/Energy_Expertise/CO2_Emissions_Clean_Energy.aspx Fig.5 U.S Natural Gas Production, prediction from 1990 to 2035 year]]] | ||

| Line 192: | Line 192: | ||

===Taxonomy for various technical challenges in tight gas recovery=== | ===Taxonomy for various technical challenges in tight gas recovery=== | ||

| − | <mm>[[Technical challenges in tight gas | + | <mm>[[Technical challenges in tight gas recovery1.mm|Interactive Mindmap|center|title Technical challenges in tight gas recovery]]</mm> |

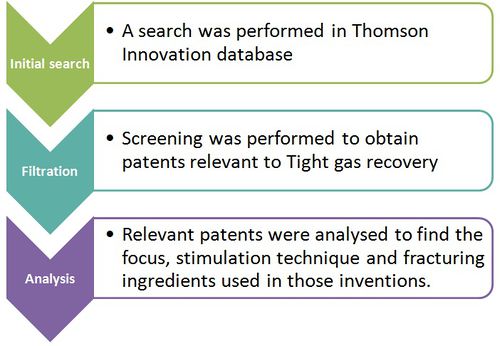

=Methodology for Patent Search= | =Methodology for Patent Search= | ||

| Line 216: | Line 216: | ||

*'''Stimulation''': Stimulation, fracturing etc. | *'''Stimulation''': Stimulation, fracturing etc. | ||

| − | [[Image:Process | + | [[Image:Process flow steps for patent analysis .jpg|centre|thumb|500px|Process-flow for patent analysis]] |

| + | |||

| + | ===Insights from patent analysis=== | ||

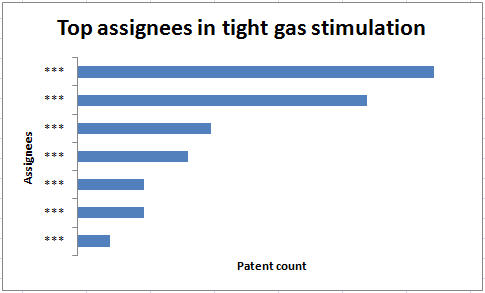

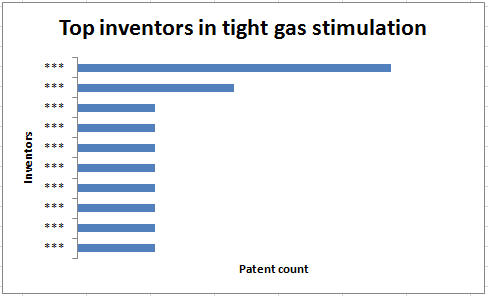

| + | All the patents obtained from the database were filtered to find out the most relevant patents, this process included going through the full text of the patent. Relevant patents related to stimulation technique for tight gas formations were found. This was followed by a detailed analysis of the relevant records. All the patents were analyzed to capture the focus of the patent, stimulation technique described in the invention and the fracturing ingredients used in the invention. The analyses of the patents lead to following observations: | ||

| + | |||

| + | ====Top Assignees and Inventors==== | ||

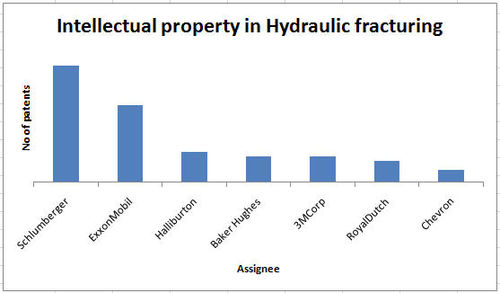

| + | Schlumberger, Exxonmobil and Halliburton feature among the top assignees. | ||

| + | [[Image:doc1.jpeg|center|500px]] | ||

| + | |||

| + | |||

| + | [[Image:doc2.jpeg|center|500px]] | ||

| + | |||

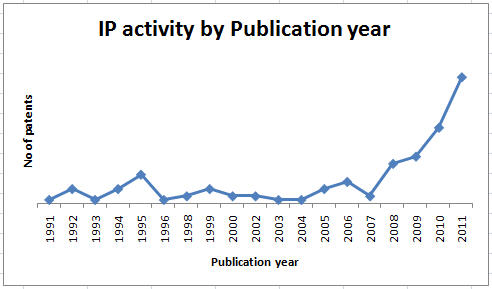

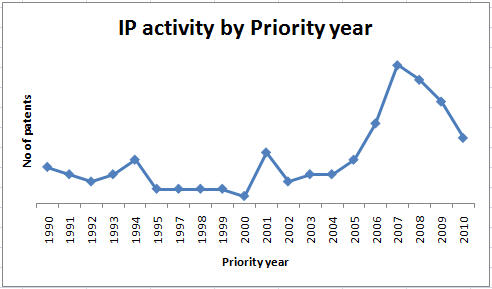

| + | ===IP Activity=== | ||

| + | |||

| + | [[Image:IP activity pub year.jpg|center|500px]] | ||

| + | |||

| + | |||

| + | [[Image:IP activity prio year.jpg|center|500px]] | ||

| + | |||

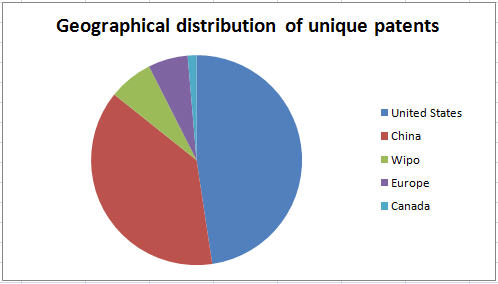

| + | ====Geographical Distribution of patents==== | ||

| + | a) By unique families | ||

| + | Since the unique family retrieved from Thomson Innovation Database was downloaded by keeping US as a first priority, hence one can see that US leads in the chart. | ||

| + | |||

| + | [[Image:docb.jpeg|center|500px]] | ||

| + | |||

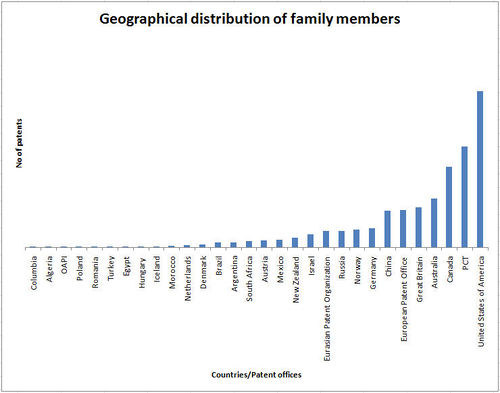

| + | b) Total patent families filed across the globe | ||

| + | |||

| + | [[Image:Patentfamilies.jpeg|center|500px]] | ||

| + | |||

| + | ==Technology and Scientific Information Search Strategy== | ||

| + | A search for extracting scientific articles was conducted. | ||

| + | |||

| + | '''Database used''': Engineering Village (Compendex) | ||

| + | |||

| + | '''Scope''': Subject/Title/Abstract | ||

| + | |||

| + | '''Years Searched''': 1990-2012 | ||

| + | |||

| + | '''Date of search''': 02nd January 2012 | ||

| + | |||

| + | '''Criteria for filtering''': Only those articles related to stimulation or fracturing techniques for tight gas recovery were considered as relevant. Articles related to modeling were considered as OFF target documents. Duplicate articles were removed. | ||

| + | |||

| + | =Taxonomy for patent analysis for tight gas recovery= | ||

| + | |||

| + | <mm>[[Tight Gas Recovery Analysis Taxonomy1.mm|800px|Interactive Mindmap|center|title Taxonomy for patent analysis]]</mm> | ||

| + | |||

| + | =Stimulation Techniques= | ||

| + | |||

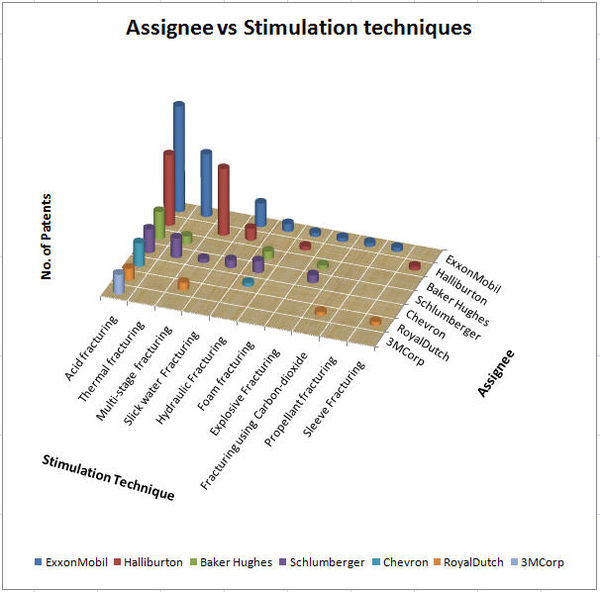

| + | ===Graphical representation of Assignee vs Stimulation techniques=== | ||

| + | [[Image:Assignee vs Stimulation Technique.jpg|center|600px]] | ||

| + | |||

| + | |||

| + | Different types of fracturing techniques are used for stimulation of tight gas reservoir. Here we have covered the patents and articles which are focusing on the application of fracturing technique for the development of the tight gas reservoir. | ||

| + | |||

| + | ==Hydraulic Fracturing== | ||

| + | |||

| + | ===Graphical Representation of Assignee's holding patents of Hydraulic fracturing=== | ||

| + | [[Image:Ass Hydraulic.jpg|center|500px]] | ||

| + | |||

| + | '''Table: Hydraulic fracturing patent of different Companies.''' | ||

| + | |||

| + | {|border="2" cellspacing="0" cellpadding="4" width="80%" | ||

| + | |align = "center" bgcolor = "#9BBB59" colspan = "4"|'''Hydraulic Fracturing''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''S.No''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Assignee''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Patent''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Comment''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59" rowspan = "2"|'''1''' | ||

| + | |align = "center" rowspan = "2"|Halliburton | ||

| + | |align = "center"|<font color="#0000FF"><u>[http://appft1.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PG01&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.html&r=1&f=G&l=50&s1=%2220110209868%22.PGNR.&OS=DN/20110209868&RS=DN/20110209868 US20110209868A1]</u></font> | ||

| + | |Fracturing of stress altered formation using signaling subsystem communicably coupled with injection tools installed in the well bore. | ||

| + | |- | ||

| + | |align = "center"|<font color="#0000FF"><u>[http://appft1.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PG01&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.html&r=1&f=G&l=50&s1=%2220090288833%22.PGNR.&OS=DN/20090288833&RS=DN/20090288833 US20090288833A1]</u></font> | ||

| + | |Fracturing of multiple ultra-shot radius laterals from a parent well | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59" rowspan = "3"|'''2''' | ||

| + | |align = "center" rowspan = "3"|Schlumberger | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''3''' | ||

| + | |align = "center"|<nowiki>### </nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''4''' | ||

| + | |align = "center"|<nowiki>### </nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''5''' | ||

| + | |align = "center"|<nowiki>### </nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | |||

| + | These sections now concentrate on the work done by the companies or institutes. | ||

| + | |||

| + | ===Halliburton=== | ||

| + | |||

| + | [http://appft1.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PG01&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.html&r=1&f=G&l=50&s1=%2220110209868%22.PGNR.&OS=DN/20110209868&RS=DN/20110209868 US20110209868A1] titled "Fracturing a '''stress-altered subterranean formation'''" by Halliburton. Fracturing of a stress- altered subterranean formation is difficult to perform. Fracturing of stress altered formation using signaling subsystem communicably coupled with injection tools installed in the well bore.'''Signaling subsystem''' adapted to transmit control signals from a well bore surface to each injection tool to change the state of the injection tool according to stress condition....[Contd] | ||

| + | |||

| + | [http://appft1.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PG01&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.html&r=1&f=G&l=50&s1=%2220090288833%22.PGNR.&OS=DN/20090288833&RS=DN/20090288833 US20090288833A1] titled "System and methods for constructing and fracture stimulating multiple ultra-short radius laterals from a parent well" by Halliburton. Hydrocarbons are often dispersed in a stacked sequence in the reservoir. The reservoir also contains water bearing zones. Conventional equipment cannot be used for drilling and stimulation of multi lateral well as they are very time consuming, and expensive in nature....[Contd] | ||

| + | |||

| + | ===Schlumberger=== | ||

| + | .....[Contd] | ||

| + | |||

| + | ===Information from the Article=== | ||

| + | |||

| + | Many authors have talked about massive hydraulic fracturing <u>Ahmed et al</u>. in 1979, <u>Hanson, in 1981 </u>and <u>Schubarth et al. in 2006</u>. '''Massive hydraulic fracturing '''(MHF) is a primary candidate for stimulating production from the tight gas reservoirs in the U.S. MHF is a more recent application that differs from hydraulic fracturing in that more fluid and proppant are pumped to create more extensive fractures in the reservoir.... [Contd] | ||

| + | |||

| + | ===Summary of Hydraulic fracturing=== | ||

| + | |||

| + | Various companies are using or developing different techniques for performing hydraulic fracturing in different operating condition and reservoirs. | ||

| + | |||

| + | ==Multi Stage Fracturing== | ||

| + | '''Table: Multi Stage Fracturing patent of different Companies.''' | ||

| + | |||

| + | {|border="2" cellspacing="0" cellpadding="4" width="80%" | ||

| + | |align = "center" bgcolor = "#9BBB59" colspan = "4"|'''Multi Stage Fracturing''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''S.No''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Assignee''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Patent''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Comment''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|1 | ||

| + | |align = "center"|'''Schlumberger''' | ||

| + | |align = "center"|<font color="#0000FF"><u>[http://appft1.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PG01&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.html&r=1&f=G&l=50&s1=%2220110024121%22.PGNR.&OS=DN/20110024121&RS=DN/20110024121 US20110024121A1]</u></font> | ||

| + | ||Fracturing multilateral wellbores in a single mobilization of fracturing unit. | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|2 | ||

| + | |align = "center"|'''####''' | ||

| + | |align = "center"|**** | ||

| + | |align = "center"|**** | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | These sections now concentrate on the work done by the companies or institutes. | ||

| + | ===Schlumberger=== | ||

| + | |||

| + | <font color="#0000FF"><u>[http://appft1.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PG01&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.html&r=1&f=G&l=50&s1=%2220110024121%22.PGNR.&OS=DN/20110024121&RS=DN/20110024121 US20110024121A1] </u></font> titled "Method and apparatus for multilateral multistage stimulation of a well" by Schlumberger. It employs a '''continuous multistage fracturing of lateral wells by wellbore isolation and focused fracturing placement'''. Fracturing multilateral wellbores in a single mobilization of fracturing unit(s) by sequentially connecting a fracturing tubing string to each lateral wellbore, directing a fracturing fluid at that specific lateral wellbore in a manner to achieve the desired fracturing and isolating those lateral wellbore after it is fractured....[Contd] | ||

| + | |||

| + | ===Information from the Articles=== | ||

| + | |||

| + | Saldungary et. al., 2008 of '''Schlumberger''', studied on Efficient Multifractured Horizontal Completion change the economic equation in Latin America; they have discussed the effect of '''Effective Multistage Fracturing System (EMFS). '''The system consists of mechanical open hole packers, are capable of withstanding high differential pressures at high operating temperatures, with specially designed fracturing ports (FracPorts), are located between the packers....[Contd] | ||

| + | |||

| + | ===Summary of Multi Stage Fracturing=== | ||

| + | |||

| + | From the patents, it's observed that Schlumberger employs a continuous multistage fracturing of lateral wells and focused fracturing placement....[Contd] | ||

| + | From the articles, it can be concluded Schlumberger, is focused on effective multistage fracturing system (EMFS)....[Contd] | ||

| + | |||

| + | ==Slickwater Fracturing== | ||

| + | |||

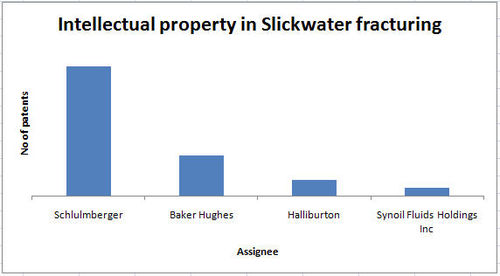

| + | ===Graphical representation of Assignee's holding patents of Slickwater fracturing === | ||

| + | [[Image:Assignee Slickwater.jpg|center|500px]] | ||

| + | |||

| + | |||

| + | '''Table: Slickwater Fracturing patent of different Companies.''' | ||

| + | |||

| + | {|border="2" cellspacing="0" cellpadding="4" width="85%" | ||

| + | |align = "center" bgcolor = "#9BBB59" colspan = "4"|'''Slickwater Fracturing''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''S.No''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Assignee''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Patent''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Comment''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59" rowspan = "2"|'''1''' | ||

| + | |align = "center" rowspan = "2"|'''Baker Hughes''' | ||

| + | |align = "center"|<font color="#0000FF"><u>[http://appft1.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PG01&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.html&r=1&f=G&l=50&s1=%2220100089580%22.PGNR.&OS=DN/20100089580&RS=DN/20100089580 US20100089580A1]</u></font> | ||

| + | |Performing fracturing method by combining proppant free stage and proppant ladden stage in two stages helps in reducing the conductivity damage. | ||

| + | |- | ||

| + | |align = "center"|<font color="#0000FF"><u>[http://patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PALL&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.htm&r=1&f=G&l=50&s1=7699106.PN.&OS=PN/7699106&RS=PN/7699106 US7699106B2]</u></font> | ||

| + | |Hydraulic fracturing treatment by using ULW (Ultra lightweight) proppant and low viscosity slick water fracturing fluid. | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59" rowspan = "2"|'''2''' | ||

| + | |align = "center" rowspan = "2"|<nowiki>### </nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''3''' | ||

| + | |align = "center"|<nowiki>### </nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | |||

| + | These sections now concentrate on the work done by the companies or institutes. | ||

| + | |||

| + | ===Baker Hughes=== | ||

| + | |||

| + | [http://appft1.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PG01&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.html&r=1&f=G&l=50&s1=%2220100089580%22.PGNR.&OS=DN/20100089580&RS=DN/20100089580 US20100089580A1] titled "Method of enhancing fracture conductivity" by Baker Hughes. In hydraulic fracturing, fracturing fluid containing gelled fluid, viscosifying polymers and surfactants used to provide fluid viscosity for proppant packing but often leads to the formation of filter cake which causes conductivity damage....[Contd] | ||

| + | |||

| + | [http://patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PALL&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.htm&r=1&f=G&l=50&s1=7699106.PN.&OS=PN/7699106&RS=PN/7699106 US7699106B2] titled "Method for reducing fluid loss during hydraulic fracturing or sand control treatment" by Baker Hughes. Hydraulic fracturing treatment using high ASG (Apparent Specific Gravity) proppant and high viscous fracturing fluid often leads to....[Contd] | ||

| + | |||

| + | ===Information from the Articles=== | ||

| + | |||

| + | Pearce et. al., 2002 of The '''Houston Exploration Co '''studied on successfully pushing the limits in tight gas fracturing. A South Texas tight gas field was fractured using '''LPF (Lower-polymer fluid) system'''. LPF system avoided the proppant damage due to less polymer residue, and improved well productivity through increased fracture conductivity....[Contd] | ||

| + | |||

| + | ===Summary of Slickwater fracturing=== | ||

| + | |||

| + | Baker Hughes focused on hydraulic fracturing treatment by using ULW (Ultra lightweight) proppant and low viscosity slick water fracturing fluid. And performing fracturing method in two stages helps in reducing the conductivity damage....[Contd] | ||

| + | |||

| + | ==Acid Fracturing== | ||

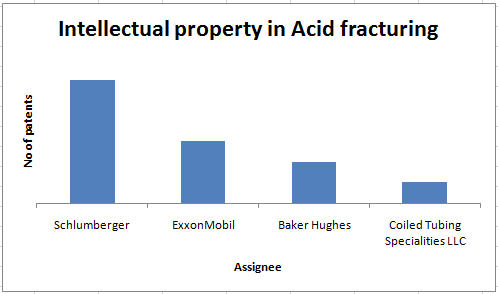

| + | ===Graphical representation of Assignee's holding patents of Acid fracturing=== | ||

| + | |||

| + | [[Image:Assignee acid.jpg|center|500px]] | ||

| + | |||

| + | |||

| + | '''Table: Acid Fracturing patent of different Companies.''' | ||

| + | |||

| + | {|border="2" cellspacing="0" cellpadding="4" width="80%" | ||

| + | |align = "center" bgcolor = "#9BBB59" colspan = "4"|'''Acid Fracturing''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''S.No''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Assignee''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Patent''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Comment''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59" rowspan = "2"|'''1''' | ||

| + | |align = "center" rowspan = "2"|'''Schlumberger''' | ||

| + | |<font color="#0000FF"><u>[http://patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PALL&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.htm&r=1&f=G&l=50&s1=7380602.PN.&OS=PN/7380602&RS=PN/7380602 US7380602B2]</u></font> | ||

| + | |Treating a subterranean carbonate with a fluid comprising of an acid, chelating agent, or betaine surfactant. | ||

| + | |- | ||

| + | |<font color="#0000FF"><u>[http://patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PALL&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.htm&r=1&f=G&l=50&s1=6828280.PN.&OS=PN/6828280&RS=PN/6828280 US6828280B2]</u></font> | ||

| + | |Stimulation of hydrocarbon production from low permeability formations by hydraulic fracturing, acid fracturing, and hydraulic fracturing followed by gravel packing in a single operation | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''2''' | ||

| + | |align = "center"|<nowiki>### </nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''3''' | ||

| + | |align = "center"|<nowiki>### </nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | These sections now concentrate on the work done by the companies or institutes. | ||

| + | |||

| + | ===Schlumberger=== | ||

| + | |||

| + | [http://patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PALL&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.htm&r=1&f=G&l=50&s1=7380602.PN.&OS=PN/7380602&RS=PN/7380602 US7380602B2] titled "Composition and method for treating a subterranean formation" by Schlumberger. Matrix acidizing treatment leads to the problem of (1) inadequate radial penetration (portions of the formation away from the wellbore in the radial direction is untouched by the acid because all of the acid reacts before it can get there); (2)....[Contd] | ||

| + | |||

| + | [http://patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PALL&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.htm&r=1&f=G&l=50&s1=6828280.PN.&OS=PN/6828280&RS=PN/6828280 US6828280B2] titled "Methods for stimulating hydrocarbon production" by Schlumberger. In hydraulic and acid fracturing, a first, viscous fluid called a "pad" is typically injected into the formation to initiate and propagate the fracture and often to contribute to fluid loss control and mainly consist of polymers. Methods are provided for stimulation of hydrocarbon production from low permeability formations by hydraulic fracturing, '''acid fracturing'''....[Contd] | ||

| + | |||

| + | ===Information from the Articles=== | ||

| + | |||

| + | Al-Ghurairi et. al., 2003 of '''Saudi Aramco''', studied on Successful Fracturing through optimizations steps for high rate deep gas wells in carbonate reservoirs of Saudi Arabia where acid fracturing treatments was applied at Khuff reservoir, gelled HCl acid system, emulsified acid (consisting of HCl acid and diesel) was tested for tight reservoirs to achieve deeper penetration....[Contd] | ||

| + | |||

| + | ===Summary of Acid fracturing=== | ||

| + | |||

| + | Schlumberger is using acid fracturing technique for subterranean carbonate with a fluid comprising of an acid, chelating agent, or betaine surfactant. And similarly along with hydraulic fracturing also acid fracturing was tried....[Contd] | ||

| + | |||

| + | ==Carbon dioxide Fracturing== | ||

| + | '''Table: Carbon dioxide Fracturing patent of different Companies.''' | ||

| + | {|border="2" cellspacing="0" cellpadding="4" width="70%" | ||

| + | |align = "center" bgcolor = "#9BBB59" colspan = "4"|'''Carbon dioxide Fracturing''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''S.No''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Assignee''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Patent''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Comment''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''1''' | ||

| + | |align = "center"|'''Schlumberger''' | ||

| + | |align = "center"|<font color="#0000FF"><u>[http://patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PALL&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.htm&r=1&f=G&l=50&s1=7726404.PN.&OS=PN/7726404&RS=PN/7726404 US7726404B2]</u></font> | ||

| + | |Use of carbon-dioxide-based fracturing fluids | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''2''' | ||

| + | |align = "center"|<nowiki>### </nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''3''' | ||

| + | |align = "center"|<nowiki>### </nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | These sections now concentrate on the work done by the companies or institutes. | ||

| + | ===Schlumberger=== | ||

| + | |||

| + | [http://patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PALL&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.htm&r=1&f=G&l=50&s1=7726404.PN.&OS=PN/7726404&RS=PN/7726404 US7726404B2] titled "Use of carbon-dioxide-based fracturing fluids" by Schlumberger. Conventional hydraulic and slickwater fracturing leads to the problem of fluid leak off, well damage and water blocks. Treatment of shale-containing subterranean formation is carried out by forming a '''carbon dioxide treatment fluid''' having a viscosity of less than about 10 mPa-s at a shear rate of about 100 s.sup.-1. and comprising of 90% by weight carbon dioxide and a surfactant....[Contd] | ||

| + | |||

| + | ===Summary of Carbon dioxide Fracturing=== | ||

| + | |||

| + | Schlumberger has developed carbon-dioxide-based fracturing fluids and shows CO<sub>2</sub> has ability to displace methane from the shale-containing formations....[Contd]<br> | ||

| + | Articles say Schlumberger has developed new CO<sub>2</sub> viscoelastic surfactant (VES) system, which is known as ClearFRAC....[Contd] | ||

| + | |||

| + | ==Foam Fracturing== | ||

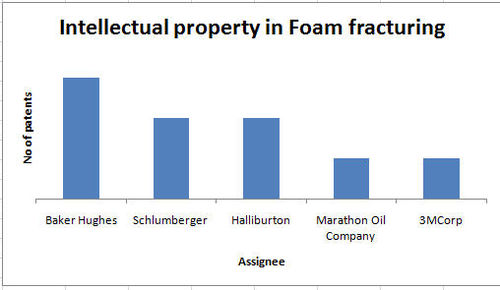

| + | ===Graphical representation of assignee’s holding patents of foam fracturing=== | ||

| + | [[Image:Ass foam.jpg|center|500px]] | ||

| + | |||

| + | '''Table: Foam Fracturing patent of different Companies.''' | ||

| + | {|border="2" cellspacing="0" cellpadding="4" width="102%" | ||

| + | |align = "center" bgcolor = "#9BBB59" colspan = "4"|'''Foam Fracturing''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''S.No''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Assignee''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Patent''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Comment''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59" rowspan = "2"|'''1''' | ||

| + | |align = "center" rowspan = "2"|Halliburton | ||

| + | |align = "center"|<font color="#0000FF"><u>[http://patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PALL&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.htm&r=1&f=G&l=50&s1=5990052.PN.&OS=PN/5990052&RS=PN/5990052 US5990052A]</u></font> | ||

| + | |Foamed fracturing fluid | ||

| + | |- | ||

| + | |align = "center"|<font color="#0000FF"><u>US5310002A</u></font> | ||

| + | |Microemulsion generating component and foaming agent component function to enhance the ability of the compositions to remove any blocks of fluids interlocked with gas in formations | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''2''' | ||

| + | |align = "center"|<nowiki>### </nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''3''' | ||

| + | |align = "center"|<nowiki>### </nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | ===Halliburton=== | ||

| + | |||

| + | [http://patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PALL&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.htm&r=1&f=G&l=50&s1=5990052.PN.&OS=PN/5990052&RS=PN/5990052 US5990052A] titled "Foamed fracturing fluid" by Halliburton. Fracturing fluids must provide an optimal balance between minimizing fluid leakage, filtercake buildup thickness and filtercake removal as it impairs the permeability and conductivity of the formation. Need of a foamed fracturing fluid that has the performance advantages of crosslinked gel foams but which deposits a filtercake which can be substantially completely removed after the fracturing operation is completed....[Contd] | ||

| + | |||

| + | <font color="#0000FF"><u>US5310002A </u></font>titled "Gas well treatment compositions and methods" by Halliburton <font color="#FF0000">(Also in foam)</font>. Treatment fluids or fracturing fluids remaining in the pores of the formation and water blocks leads to kind of damage that impairs subsequent hydrocarbon production from the formation. The microemulsion generating component and foaming agent component function to enhance the ability of the compositions to remove any blocks....[Contd] | ||

| + | |||

| + | ===Information from the Articles=== | ||

| + | Walser et. al., 2001 of '''BJ Services Company '''USA, studied on Production response from Southeastern New Mexico Morrow wells stimulated with binary foam. Stimulation and fracturing of Morrow formation in south eastern New Mexico was performed with binary foam fracturing fluid. Stimulation fluid contains liquid CO<sub>2</sub>, gaseous nitrogen, gelled 2% KCl water, methanol and hydrated polymer are added in the base gelled water....[Contd] | ||

| + | |||

| + | ===Summary of Foam Fracturing=== | ||

| + | |||

| + | Halliburton disclosed a new crosslinked foamed fracturing fluids and also using foam agent in combination with microemulsion to remove any blocks of fluids in the reservoir....[Contd] | ||

| + | |||

| + | ==Explosive Fracturing== | ||

| + | '''Table: Explosive Fracturing patent of different Companies.''' | ||

| + | {|border="2" cellspacing="0" cellpadding="4" width="80%" | ||

| + | |align = "center" bgcolor = "#9BBB59" colspan = "4"|'''Explosive Fracturing''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''S.No''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Assignee''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Patent''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Comment''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|1 | ||

| + | |'''ExxonMobil''' | ||

| + | |align = "center"|<font color="#0000FF"><u>[http://www.wipo.int/pctdb/en/wo.jsp?WO=2011115723 WO2011115723A1]</u></font> | ||

| + | |System and method for fracturing rock in tight reservoirs by explosive fracturing | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|2 | ||

| + | |align = "center"|<nowiki>### </nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | |||

| + | These sections now concentrate on the work done by the companies or institutes. | ||

| + | ===ExxonMobil=== | ||

| + | |||

| + | [http://www.wipo.int/pctdb/en/wo.jsp?WO=2011115723 WO2011115723A1] titled "System and method for fracturing rock in tight reservoirs" by ExxonMobil. A conventional hydraulic and explosive fracturing lead to pervasive, isotropic permeability increase in the rock of the formation but does not create a spatially extensive network of fractures.'''Explosion fracturing is done in the lateral wells by using a squash head charge'''....[Contd] | ||

| + | |||

| + | ===Information from the Articles=== | ||

| + | |||

| + | Cui et. al., 2006 PetroChina studied In-fracture Explosive Hydraulic fracturing fluid and its rheological study. An experimental test was performed using In Fracture Explosive Hydraulic Fracturing Fluid (IFEHFF) which is a combination of hydraulic fracturing fluid properties and an explosion fluid (TNT). According to simulator calculation, the system can generate fractures with desired geometry and suspend explosive evenly in the fractures. | ||

| + | |||

| + | ===Summary of Explosive Fracturing=== | ||

| + | |||

| + | Both Exxonmobil has worked on increasing the permeability of the formation by inducing explosive fracturing. Exxonmobil has adopted a technique of drilling lateral wells and placing the squash head charge in the wells....[Contd] | ||

| + | |||

| + | ==Sleeve fracturing== | ||

| + | |||

| + | {|border="2" cellspacing="0" cellpadding="4" width="80%" | ||

| + | |align = "center" bgcolor = "#9BBB59" colspan = "4"|'''Sleeve fracturing''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''S.No''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Assignee''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Patent''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Comment''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|1 | ||

| + | |align = "center"|'''Coiled Tubing Specialties''' | ||

| + | |align = "center"|<font color="#0000FF"><u>[http://appft1.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PG01&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.html&r=1&f=G&l=50&s1=%2220110290561%22.PGNR.&OS=DN/20110290561&RS=DN/20110290561 US20110290561A1 ]</u></font> | ||

| + | ||Downhole Hydraulic Jetting Assembly, and Method for Stimulating a Production Wellbore | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | |||

| + | |||

| + | ===Coiled Tubing Specialties=== | ||

| + | |||

| + | [http://appft1.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PG01&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.html&r=1&f=G&l=50&s1=%2220110290561%22.PGNR.&OS=DN/20110290561&RS=DN/20110290561 US20110290561A1] titled "Downhole Hydraulic Jetting Assembly, and Method for Stimulating a Production Wellbore" by Coiled Tubing Specialties. Need of a method for forming lateral boreholes from a parent wellbore for hydrocarbon recovery from the formation. It provides a new stimulation technique for hydrocarbon-producing formation....[Contd] | ||

| + | |||

| + | ===Information from the Articles=== | ||

| + | |||

| + | Rahim et. al., 2011 of '''Saudi Aramco '''studied on success criteria for Multistage Fracturing of tight gas in Saudi Arabia. Open Hole Multi Stage (OHMS) fracturing was used to improve hydrocarbon production from the deep gas carbonate sandstone wells in Saudi Arabia. Here authors talk about dual sleeve hydraulic fracturing device....[Contd] | ||

| + | |||

| + | ===Summary of Sleeve Fracturing=== | ||

| + | ....[Contd] | ||

| + | |||

| + | ==Hydrocarbon recovery by using biogenic materials combined with Pneumatic fracturing== | ||

| + | |||

| + | {|border="2" cellspacing="0" cellpadding="4" width="80%" | ||

| + | |align = "center" bgcolor = "#9BBB59" colspan = "4"|'''Hydrocarbon recovery by using biogenic materials combined with pneumatic fracturing''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''S.No''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Assignee''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Patent''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Comment''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|1 | ||

| + | |align = "center"|'''Groundwater Services Inc''' | ||

| + | |align = "center"|<font color="#0000FF"><u>[http://www.wipo.int/pctdb/en/wo.jsp?WO=2008041990 WO2008041990A1]</u></font> | ||

| + | ||Stimulating anaerobic biologic production of methane from non-liquid hydrocarbon-bearing subsurface formations | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | These sections now concentrate on the work done by the companies or institutes. | ||

| + | |||

| + | ===Groundwater Services Inc.=== | ||

| + | [http://www.wipo.int/pctdb/en/wo.jsp?WO=2008041990 WO2008041990A1] titled "Methods and systems for '''stimulating biogenic''' production of natural gas in a subterranean formation" by Groundwater Services Inc. A new method and systems for stimulating anaerobic biologic production of methane from non-liquid hydrocarbon-bearing subsurface formations. It comprises of subsurface formation comprising a hydrocarbon;....[Contd] | ||

| + | |||

| + | ===Information from the Article=== | ||

| + | |||

| + | '''Lan et. al., 2010 '''of '''Drilling Research Institute of Shengli Oilfield''', Dongying, Shandong studied on application of '''bio-enzymatic '''completion fluid in the tight sand gas reservoirs of ordos Daniudi Gas field. Solid free brine completion fluid shows a little effect on the formation damage, water blocking and solid slugging with small particle. An environment acceptable and nontoxic bio-enzymatic completion fluid was prepared and tested in 15 horizontal wells of Ordos Dainiudi gas field....[Contd] | ||

| + | |||

| + | ===Summary of Hydrocarbon recovery by using biogenic materials combined with Pneumatic fracturing=== | ||

| + | ....[Contd] | ||

| + | |||

| + | ==Chemical reaction induced pressure pulses fracturing== | ||

| + | |||

| + | {|border="2" cellspacing="0" cellpadding="4" width="80%" | ||

| + | |align = "center" bgcolor = "#9BBB59" colspan = "4"|'''Chemical reaction induced pressure pulses fracturing''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''S.No''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Assignee''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Patent''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Comment''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|1 | ||

| + | |align = "center"|'''Univ Louisiana State''' | ||

| + | |align = "center"|<font color="#0000FF"><u>[http://patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PALL&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.htm&r=1&f=G&l=50&s1=5083615.PN.&OS=PN/5083615&RS=PN/5083615 US5083615A]</u></font> | ||

| + | ||The pressure pulses are generated by the reaction of aluminum alkyl with either water, or alcohol, or acid. | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | These sections now concentrate on the work done by the companies or institutes. | ||

| + | ===Univ Louisiana State=== | ||

| + | |||

| + | [http://patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PALL&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.htm&r=1&f=G&l=50&s1=5083615.PN.&OS=PN/5083615&RS=PN/5083615 US5083615A] titled "Aluminum alkyls used to create multiple fractures" by Univ Louisiana State. The pressure rise after fracturing is the important parameter in determining the fracture pattern. The time required for the pressure rise is found to be longest in hydraulic fracturing. So to control the fracture pattern the pressure rise time has to be controlled....[Contd] | ||

| + | |||

| + | ==Propellant Fracturing== | ||

| + | |||

| + | {|border="2" cellspacing="0" cellpadding="4" width="100%" | ||

| + | |align = "center" bgcolor = "#9BBB59" colspan = "4"|'''Propellant Fracturing''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''S.No''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Inventor''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Patent''' | ||

| + | |align = "center" bgcolor = "#9BBB59"|'''Comment''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#9BBB59"|1 | ||

| + | |align = "center"|'''Carter E. E''' | ||

| + | |<font color="#0000FF"><u>[http://patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PALL&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.htm&r=1&f=G&l=50&s1=5083615.PN.&OS=PN/5083615&RS=PN/5083615 US20110247816A1]</u></font> | ||

| + | ||Method and apparatus for increasing well productivity by using solid rocket propellant in the slots. | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | |||

| + | '''Carter E. E''' | ||

| + | [http://appft1.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d=PG01&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.html&r=1&f=G&l=50&s1=%2220110247816%22.PGNR.&OS=DN/20110247816&RS=DN/20110247816 US20110247816A1] titled "Method and Apparatus for Increasing Well Productivity" by Carter E. E.,Method and apparatus for increasing well productivity by using explosives such as '''solid rocket propellant''' are typically a mixture of ammonium perchlorate and....[Contd] | ||

| + | |||

| + | ==High pressure & high temperature (HPHT) fracturing== | ||

| + | |||

| + | '''Information from the Articles''' | ||

| + | |||

| + | Bartko et.al., 2009 of '''Saudi Aramco '''studied first application of high density fracturing fluid to stimulate a high pressure & high temperature tight gas producer sandstone formation of Saudi Arabia. High pressure and High Temperature fracturing was performed by using a new fluid system containing '''sodium bromide (Nabr brine), carboxymethylhydroxypropyl guar (CMHPG) gelling agent, zirconium cross linker and gel stabilizer'''. The new high density fracturing fluid can be used for high temperature fracturing as it can be stable upto 350 oF. Positive results obtained on field application of this new fluid system in Sarah and Qusaiba formation basin like lower injection rates, delay crosslinking time, good proppant transport capabilities, lower horsepower requirements and a safer work environment....[Contd] | ||

| + | |||

| + | |||

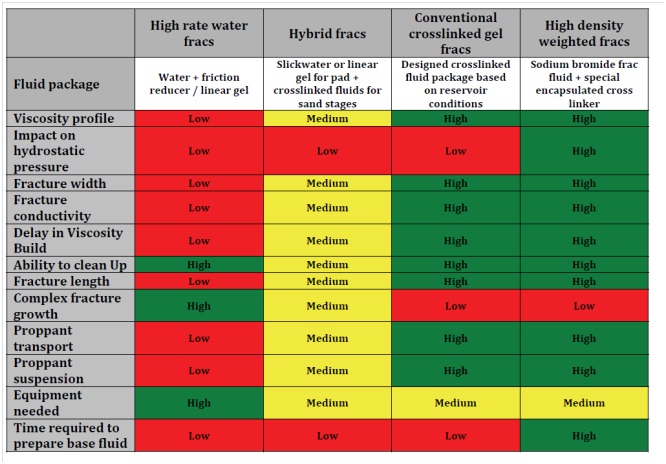

| + | Table shows the comparison made by the author between different fracturing fluids. High density weighted fracs (Sodium bromide frac fluid <nowiki>+</nowiki> special cross linker) shows higher conductivity and lower fracture complex growth as compared to other fluids while high rate water frac shows lower fracture conductivity and higher fracture complex growth. | ||

| + | [[Image:Comparison between different fracturing fluids.jpg|centre|thumb|800px|Comparison between different fracturing fluids]] | ||

| + | |||

| + | '''Summary of High pressure & high temperature (HPHT) fracturing''' | ||

| + | |||

| + | Saudi Aramco in 2009 used sodium bromide (Nabr brine)for fracturing wells....[Contd] | ||

| + | |||

| + | |||

| + | =Fracturing Fluids and Additives used= | ||

| + | |||

| + | '''Fracturing Fluid''' | ||

| + | |||

| + | Water based fracturing fluids has been widely used whereas hydrofluoric acids and hydrochloric acids are also commonly employed to dissolve some types of rock, wherein hydrochloric acids are very effective in carbonates. | ||

| + | |||

| + | |||

| + | {|border="2" cellspacing="0" cellpadding="4" width="80%" | ||

| + | |align = "center" bgcolor = "#C5BE97" colspan = "5"|'''Fracturing fluid''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#C5BE97"|'''Acid''' | ||

| + | |align = "center" bgcolor = "#C5BE97"|'''Hydrocarbon fluid''' | ||

| + | |align = "center" bgcolor = "#C5BE97"|'''Gas''' | ||

| + | |align = "center" bgcolor = "#C5BE97"|'''<nowiki>### </nowiki>''' | ||

| + | |align = "center" bgcolor = "#C5BE97"|'''<nowiki>### </nowiki>''' | ||

| + | |- | ||

| + | |align = "center"|15% Hydrochloric acid | ||

| + | |align = "center"|Metal associated-phosphate ester gelled oils, oil, frac oils, gelled oil | ||

| + | |align = "center"|Carbon dioxode | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | | | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | | | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | | | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | |} | ||

| + | |||

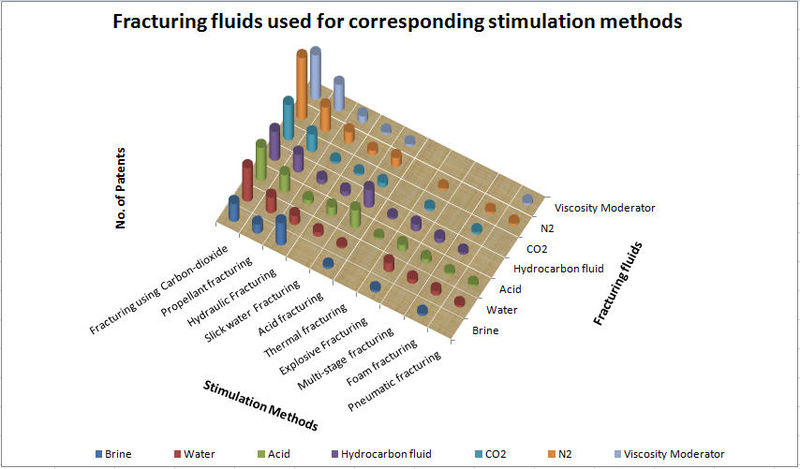

| + | ===Graphical representation of Fracturing fluids used for corresponding stimulation methods=== | ||

| + | |||

| + | [[Image:Fracturing fluids.jpg|center|800px]] | ||

| + | |||

| + | The combination of various fluids used for performing fracturing of reservoirs satisfactorily is shown in the above graph. | ||

| + | |||

| + | ==Proppant== | ||

| + | |||

| + | '''Proppant''': Allows the fractures to remain open so the gas can escape. | ||

| + | |||

| + | {|border="2" cellspacing="0" cellpadding="4" width="80%" | ||

| + | |align = "center" bgcolor = "#B2A1C7" colspan = "6"|'''Proppants''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#B2A1C7"|'''Sand''' | ||

| + | |align = "center" bgcolor = "#B2A1C7"|'''Resin-coated''' | ||

| + | |align = "center" bgcolor = "#B2A1C7"|'''Man-made ceramics''' | ||

| + | |align = "center" bgcolor = "#B2A1C7"|'''<nowiki>### </nowiki>''' | ||

| + | |align = "center" bgcolor = "#B2A1C7"|'''<nowiki>### </nowiki>''' | ||

| + | |align = "center" bgcolor = "#B2A1C7"|'''<nowiki>### </nowiki>''' | ||

| + | |- | ||

| + | |align = "center"|Sand grains | ||

| + | |align = "center"|Resin-coated sand,resin-coated sintered bauxite, resin coated ceramics | ||

| + | |align = "center"|Ceramic beads | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | | | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | | | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | | | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | | | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | |||

| + | The proppant materials have greatly improved and the technology for specially engineered proppants continues to advance. The most widely used proppant so far is naturally occurring sand for eg. white and brown sands(Ottawa, Brady respectively), quartz sand grains. To increase the strength of the proppants resin coated proppants has been come up which are Resin-coated sand, resin-coated sintered bauxite, resin coated ceramics. Ultralight weight proppants which can easily be transported by slickwater is used currently. | ||

| + | |||

| + | |||

| + | '''Ultra lightweight proppant preparation-'''Below are the additives employed by '''Baker Hughes Incorporated''' to prepare porous particulate material for use as lightweight material in liquid carbon dioxide-based well treatment systems. | ||

| + | |||

| + | |||

| + | {|border="2" cellspacing="0" cellpadding="4" width="80%" | ||

| + | |align = "center" bgcolor = "#C2D69A"|'''Additives''' | ||

| + | |align = "center" bgcolor = "#C2D69A"|'''Role''' | ||

| + | |align = "center" bgcolor = "#C2D69A"|'''<nowiki>### </nowiki>''' | ||

| + | |- | ||

| + | |align = "center"|Chemical treatment | ||

| + | |align = "center"|Nylon, polyethylene, polystyrene chemicals | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | |||

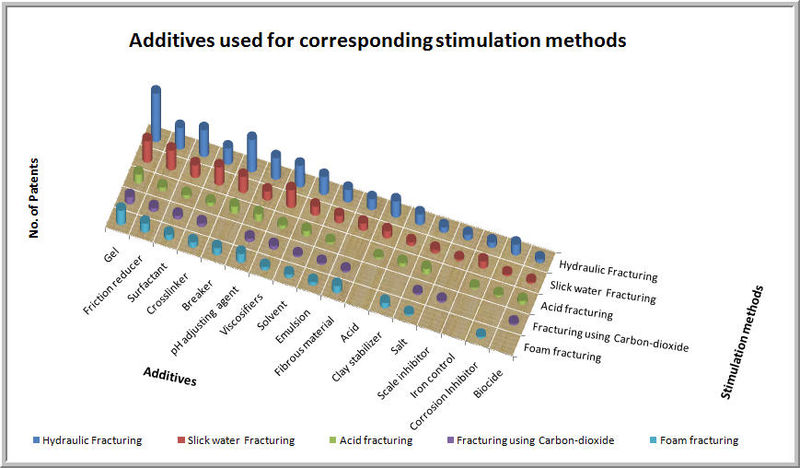

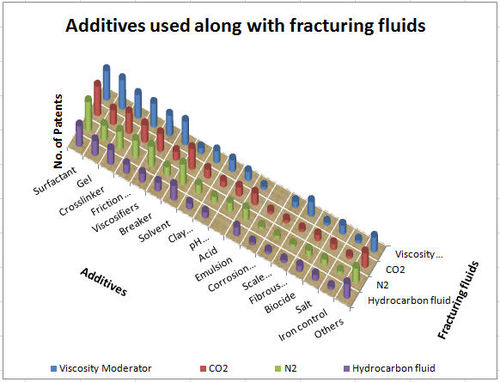

| + | ===Graphical representation of Additives used for corresponding stimulation techniques=== | ||

| + | [[Image:Additive used.jpg|800px|center]] | ||

| + | |||

| + | Hydraulic and slickwater fracturing employs viscosifiers for thickening the fracturing fluid which helps in proppant placement but the amount used in slickwater is less as compared to hydraulic as seen in the graph. The highest amount of breakers are used in hydraulic and slickwater fracturing as it degrades the polymers present in the well after fracturing. Friction reducers are mainly employed in slickwater fracturing. | ||

| + | |||

| + | The Role of the different additives used and the compounds employed for the corresponding additives are mentioned below. | ||

| + | |||

| + | ==Acid== | ||

| + | |||

| + | '''Acid:''' Helps dissolve minerals and initiate cracks in the rock. | ||

| + | |||

| + | {|border="2" cellspacing="0" cellpadding="4" width="80%" | ||

| + | |align = "center" bgcolor = "#EAF1DD" colspan = "3"|'''Acid''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''Inorganic /mineral acid''' | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''Simple organic acid''' | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''Organic aromatic acid''' | ||

| + | |- | ||

| + | |align = "center"|HCl | ||

| + | |align = "center"|Carboxylic acid | ||

| + | |align = "center"|Chlorobenzoic acid | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | ==Biocides== | ||

| + | |||

| + | '''Biocides''' are added to the mixing tanks with the gelling agents to kill bacteria which otherwise can cause problems of plugging (inhibiting the flow of gas), corrosion failures of downhole equipment, solid deposition (or scale), break down the gelling agent reducing its viscosity and ability to carry proppant. Multifunctional material comprising aldehydes; formaldehyde; dialdehydes; glutaraldehyde; hemiacetals;....[Contd] | ||

| + | |||

| + | |||

| + | ==Breaker== | ||

| + | '''Breaker''': It allows a delayed break down of the frac gel. | ||

| + | |||

| + | |||

| + | {|border="2" cellspacing="0" cellpadding="4" width="80%" | ||

| + | |align = "center" bgcolor = "#EAF1DD" colspan = "6"|'''Breaker''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#EAF1DD" colspan = "4"|'''Oxidative''' | ||

| + | |align = "center" bgcolor = "#EAF1DD" rowspan = "2"|'''<nowiki>### </nowiki>''' | ||

| + | |align = "center" bgcolor = "#EAF1DD" rowspan = "2"|'''<nowiki>### </nowiki>''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''Sulfate group''' | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''Chromate group''' | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''<nowiki>### </nowiki>''' | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''<nowiki>### </nowiki>''' | ||

| + | |- | ||

| + | |align = "center"|Ammonium persulfate – GBW 5 | ||

| + | |align = "center"|Potassium dichromate | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | | | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | The proper breaker selection for a given gel system is very important to the success of the fracturing treatment. The high viscosity frac fluid must sufficiently degrade with time to allow for high fracture fluid recovery rates on the flowback and cause minimal damage to the formation. Widely used oxidative breakers are sulfates, chromates, borates,....[Contd] | ||

| + | |||

| + | ==Corrosion inhibitor== | ||

| + | '''Corrosion inhibitor''': It prevents corrosion of equipment (pipe, pump etc) | ||

| + | |||

| + | Compounds for performing the function of corrosion inhibitors employed in fracturing treatments are Azoles, quaternary amines, formic acid....[Contd] | ||

| + | |||

| + | ==Crosslinker== | ||

| + | '''Crosslinker''': It helps in maintain the viscosity of frac fluids. | ||

| + | |||

| + | |||

| + | {|border="2" cellspacing="0" cellpadding="4" width="80%" | ||

| + | |align = "center" bgcolor = "#EAF1DD" colspan = "6"|'''Crosslinker''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''Borates''' | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''Zirconium''' | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''<nowiki>### </nowiki>''' | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''<nowiki>### </nowiki>''' | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''<nowiki>### </nowiki>''' | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''<nowiki>### </nowiki>''' | ||

| + | |- | ||

| + | |align = "center"|Borate crosslinked polymer, borate crosslinked guar | ||

| + | |align = "center"|Zirconium lactate, zirconium lactate triethanolamine and zirconium diisopropylamine lactate | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | Widely used crosslinkers are boron based and zirconium based compounds such as borate crosslinked polymer....[Contd] | ||

| + | |||

| + | ==Friction Reducers== | ||

| + | |||

| + | '''Friction Reducers''': It helps in reducing the friction of the frac fluid. | ||

| + | |||

| + | {|border="2" cellspacing="0" cellpadding="4" width="80%" | ||

| + | |align = "center" bgcolor = "#EAF1DD" colspan = "4"|'''Friction reducer''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''Polyacrylamide''' | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''Other acrylate based compound''' | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''<nowiki>### </nowiki>''' | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''<nowiki>### </nowiki>''' | ||

| + | |- | ||

| + | |align = "center"|Hydrolyzed polyacrylamide | ||

| + | |align = "center"|Polyacrylates | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"| | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | Amongst various friction reducers like acrylate based compounds (polyisobutyl methacrylate, polymethyl methacrylate),....[Contd] | ||

| + | |||

| + | ==Gel== | ||

| + | '''Gel''': It helps to suspend proppant/sand in the frac. fluids | ||

| + | |||

| + | {|border="2" cellspacing="0" cellpadding="4" width="80%" | ||

| + | |align = "center" bgcolor = "#EAF1DD" colspan = "5"|'''Gel''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''Guar/Guar gum''' | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''Cellulose and its derivatives''' | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''<nowiki>### </nowiki>''' | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''<nowiki>### </nowiki>''' | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''<nowiki>### </nowiki>''' | ||

| + | |- | ||

| + | |align = "center"|Borate crosslinked guar | ||

| + | |align = "center"|Hydroxyethyl cellulose (HEC), Carboxymethyl hydroxyethyl cellulose (CMHEC), Carboxymethyl cellulose (CMC) | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | Crosslinked Gel Fluids consisting of Guar and its derivatives such as borate cross-linked guar gel,....[Contd] | ||

| + | |||

| + | |||

| + | ==Viscosifiers== | ||

| + | |||

| + | '''Viscosifiers''': Helps in maintaining the viscosity of frac. fluids. | ||

| + | |||

| + | {|border="2" cellspacing="0" cellpadding="4" width="80%" | ||

| + | |align = "center" bgcolor = "#EAF1DD" colspan = "3"|'''Viscosifiers''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''Synthetic polymers''' | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''Polysaccharides''' | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''<nowiki>### </nowiki>''' | ||

| + | |- | ||

| + | |align = "center"|Polyvinyl polymers, substituted polyvinyl polymers, polyvinyl acetate | ||

| + | |align = "center"|Cellulose ethers, galactomannans | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"| | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | Most widely used viscosifiers are polysachharides such as guar based compounds (hydroxypropyl guar (HPG),....[Contd] | ||

| + | |||

| + | ==Clay stabilizer== | ||

| + | '''Clay stabilizer''': Prevents formation clays from swelling''' '''and includes''' '''compounds like''' '''sodium salicylate''', '''potassium chloride, sodium chloride, ....[Contd] | ||

| + | |||

| + | ==Surfactant== | ||

| + | '''Surfactant''': Used to increase the viscosity of the fracture fluid | ||

| + | |||

| + | {|border="2" cellspacing="0" cellpadding="4" width="80%" | ||

| + | |align = "center" bgcolor = "#EAF1DD" colspan = "5"|'''Surfactant''' | ||

| + | |- | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''Viscoelastic''' | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''Cationic/Anionic''' | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''<nowiki>### </nowiki>''' | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''<nowiki>### </nowiki>''' | ||

| + | |align = "center" bgcolor = "#EAF1DD"|'''<nowiki>### </nowiki>''' | ||

| + | |- | ||

| + | |align = "center"|Erucylamidopropyl betaine | ||

| + | |align = "center"|Erucylamidopropyl betaine and oleylamidopropyl betaine, oleylamidopropyl betaine | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |align = "center"|<nowiki>****</nowiki> | ||

| + | |- | ||